High-intensity biological ink material for 3D printing

A technology of bio-ink and 3D printing, which is applied in additive processing, medical science, prosthesis, etc., can solve the problems of insufficient strength, soft tissue bionic printing, etc., achieve good biocompatibility and biodegradability, and improve hydrogel Strength, effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

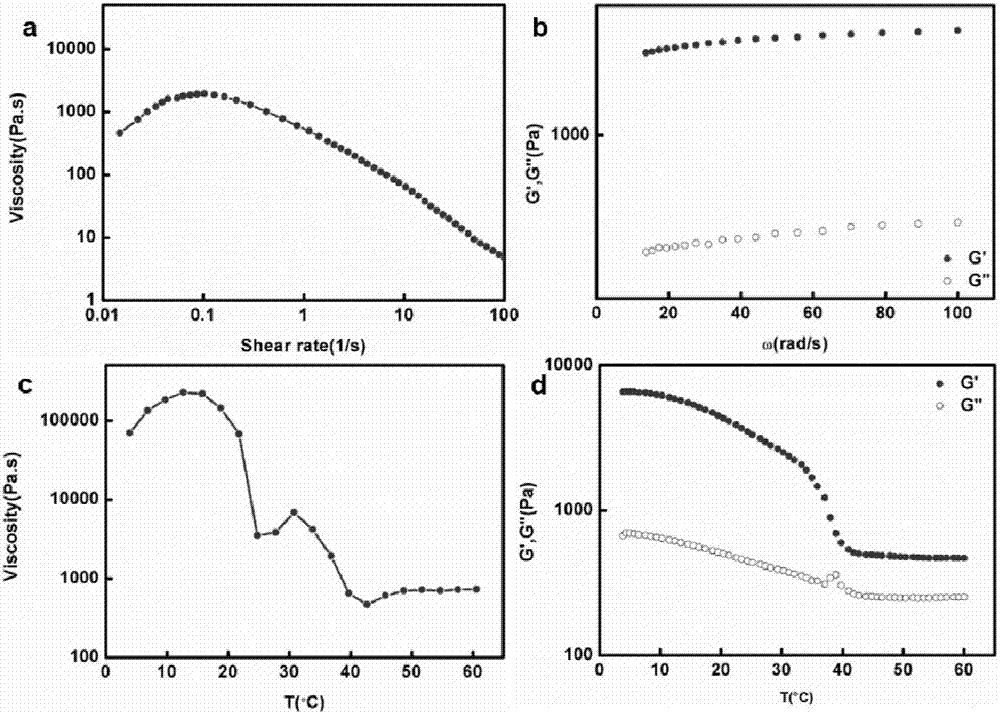

Method used

Image

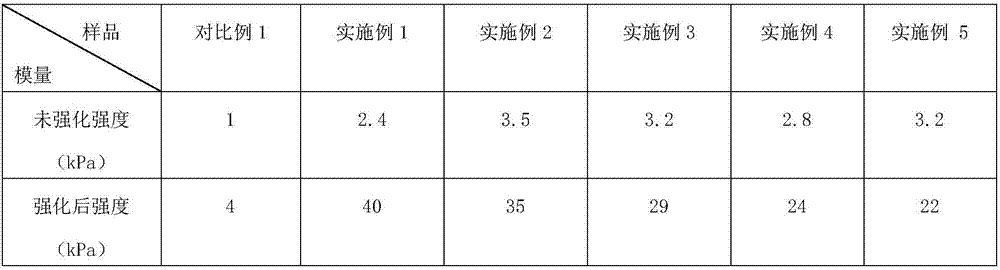

Examples

Embodiment 1

[0030] 1) adding the gelatin solution to the alginic acid aqueous solution with a mass concentration of 20%, so that the mass content of the gelatin is 2%;

[0031] 2) The silk protein solution is added to the glycerol solution with a concentration of 200 mg / ml, so that the mass fraction of silk protein in the mixed solution is 30%, and mixed evenly.

[0032] 3) Add the solution in step 1 above to the solution in step 2, and mix evenly at 80° C. for 10 minutes to obtain a bio-ink.

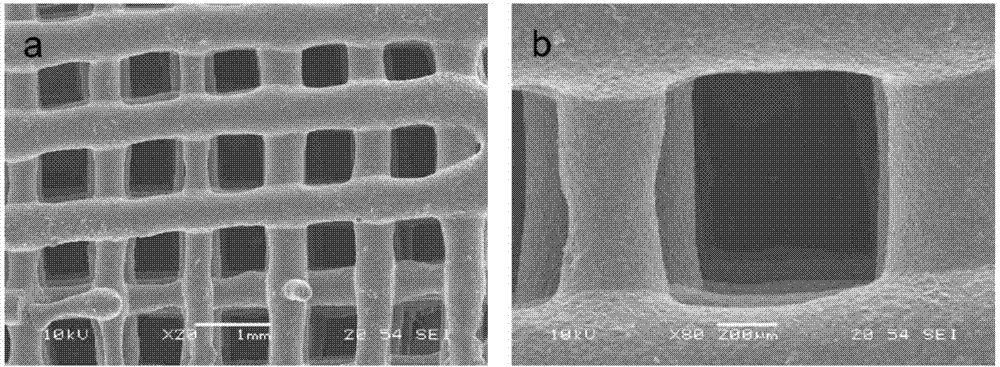

[0033] 4) The model used is Regenovo – WS bioprinter, put the above bio-ink into the printing syringe, select a needle with a diameter of 0.21mm, print air pressure of 0.40MPa, print speed of 5mm / s, set the temperature of the syringe to 40°C, and the temperature of the platform to 40°C , using air pressure to squeeze the hydrogel onto the grid support with a three-dimensional deposition size of 15*15*3mm, a square filling shape, and a filling angle of 90° on the platform.

[0034] 5) Place the s...

Embodiment 2

[0040] 1) Prepare an alginic acid solution with a mass concentration of 10%, measure 10ml of the above-mentioned alginic acid solution, add it to 5ml of 400mg / ml gelatin solution and mix evenly at 40°C.

[0041] 2) Prepare a xylitol solution with a concentration of 1 g / ml, pipette 5 ml of the above xylitol solution and add it to the silk protein solution, so that the silk protein mass fraction in the mixed solution is 20%, and make it evenly mixed.

[0042] 3) Add the mixed solution of sodium alginate and gelatin in step 1 to the solution of xylitol and silk protein in step 2 and mix evenly at 40°C to obtain a hydrogel.

[0043] 4) The model used is Regenovo3D Bioprinter TM For a bioprinter, put the above-mentioned hydrogel in the printing syringe, select a needle with a diameter of 0.41mm, print air pressure at 0.1MPa, print speed at 10mm / s, set the temperature of the syringe at 40°C, and the temperature of the platform at -5°C , using air pressure to squeeze the hydrogel on...

Embodiment 3

[0046] 1) Prepare an alginic acid solution with a mass concentration of 5%, measure 10ml of the above-mentioned alginic acid solution and add it to 5ml of 400mg / ml gelatin solution, and add 5ml of hyaluronic acid with a mass fraction of 2% and 5ml with a concentration of 1mg / ml of collagen solution, mix evenly at 40°C.

[0047] 2) Prepare a propylene glycol solution with a concentration of 1 g / ml, pipette 5 ml of the above propylene glycol solution and add it to the silk protein solution, so that the mass fraction of silk protein in the mixed solution is 15%, and make it evenly mixed.

[0048] 3) Add the mixed solution of alginic acid and gelatin in the above step 1 to the propylene glycol and silk protein in step 2, and mix uniformly at 40° C. to obtain a hydrogel.

[0049] 4) The model used is Regenovo –Pro bioprinter, put the above hydrogel in the printing syringe, select a needle with a diameter of 0.34mm, print air pressure at 0.15MPa, print speed at 10mm / s, set the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com