A kind of selenium-containing nonionic interfacial emulsifier and its preparation method and application

A non-ionic, emulsifying agent technology, applied in chemical instruments and methods, organic chemistry, transportation and packaging, etc., can solve the problem that it is difficult to eliminate the emulsifying properties of non-ionic interfacial emulsifiers, achieve superior emulsifying performance, simple preparation method, and easy synthesis The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

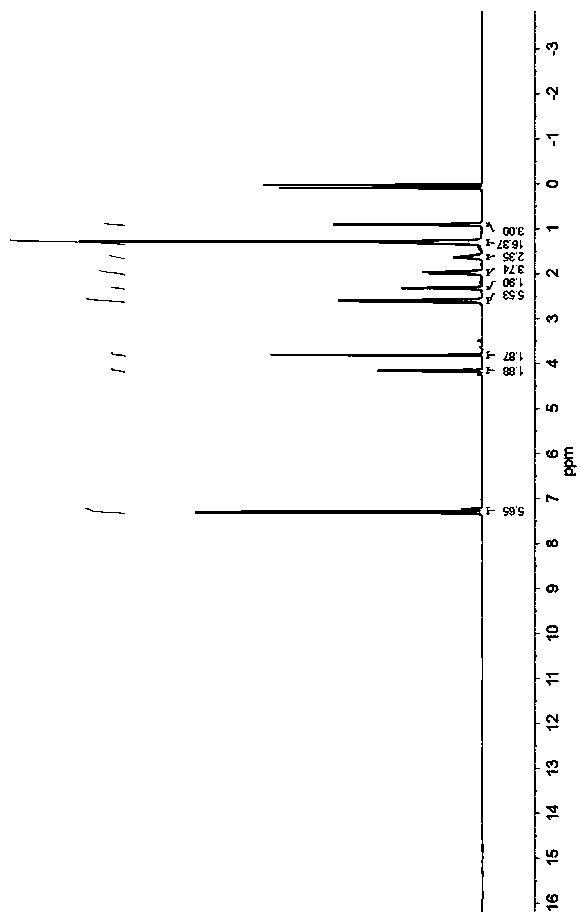

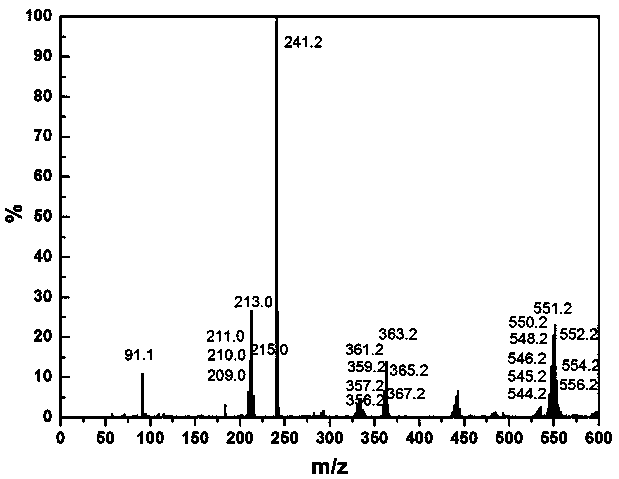

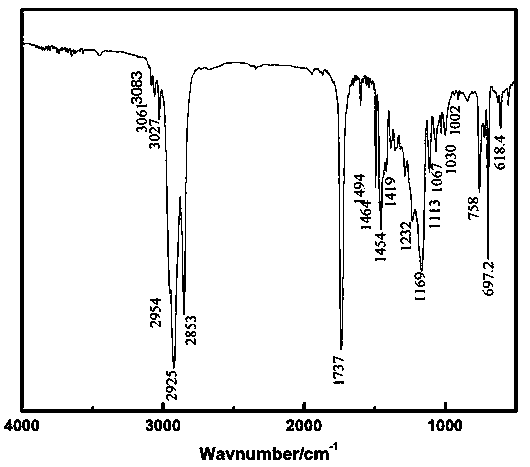

[0036] In this example, C 6 h 5 CH 2 Se(CH 2 ) 2 Se(CH 2 ) 2 The preparation method of OH is as follows:

[0037] Take 4.0 g of dibenzyldiselenide (0.012 mol) and dissolve it in 35 mL of tetrahydrofuran under the protection of nitrogen, add 2.2 g of sodium borohydride (0.048 mol) in ice water solution dropwise under the condition of ice-water bath, and react under ice-water bath for 30 Minutes later, add dropwise bromodichloroethane (or bromotrichloropropane, or bromotetrachloropropane) dissolved in tetrahydrofuran in advance in the above-mentioned system according to chlorobromoalkane: dibenzyl diselenide molar ratio 1:2.1 butane), after 0.5 hour reaction in an ice-water bath, extracted with dichloromethane to obtain the organic phase, dehydrated and evaporated the solvent, the silica gel column was eluted with a mixed solvent of 1:10 volume ratio of ethyl acetate and sherwood oil to obtain C 6 h 5 CH 2 Se(CH 2 ) 2 Cl yellow liquid, C 6 h 5 CH 2 Se(CH 2 ) 2 Cl...

Embodiment 2

[0045] In this example, C 6 h 5 CH 2 Se(CH 2 ) 3 Se(CH 2 ) 3 The preparation method of OH is as follows:

[0046] Take 4.0 g of dibenzyldiselenide (0.012 mol) and dissolve it in 35 mL of tetrahydrofuran under the protection of nitrogen, add 2.2 g of sodium borohydride (0.048 mol) in ice water solution dropwise under the condition of ice-water bath, and react under ice-water bath for 30 Minutes later, add dropwise bromodichloroethane (or bromotrichloropropane, or bromotetrachloropropane) dissolved in tetrahydrofuran in advance in the above-mentioned system according to chlorobromoalkane: dibenzyl diselenide molar ratio 1:2.1 butane), after 0.5 hour reaction in an ice-water bath, extracted with dichloromethane to obtain the organic phase, dehydrated and evaporated the solvent, the silica gel column was eluted with a mixed solvent of 1:10 volume ratio of ethyl acetate and sherwood oil to obtain C 6 h 5 CH 2 Se(CH 2 ) 3 Cl yellow liquid, C 6 h 5 CH 2 Se(CH 2 ) 3 Th...

Embodiment 3

[0055] This embodiment C 6 h 5 CH 2 Se(CH 2 ) 4 Se(CH 2 ) 4 The preparation method of OH is as follows:

[0056] Take 4.0 g of dibenzyldiselenide (0.012 mol) and dissolve it in 35 mL of tetrahydrofuran under the protection of nitrogen, add 2.2 g of sodium borohydride (0.048 mol) in ice water solution dropwise under the condition of ice-water bath, and react under ice-water bath for 30 Minutes later, add dropwise bromodichloroethane (or bromotrichloropropane, or bromotetrachloropropane) dissolved in tetrahydrofuran in advance in the above-mentioned system according to chlorobromoalkane: dibenzyl diselenide molar ratio 1:2.1 butane), after 0.5 hour reaction in an ice-water bath, extracted with dichloromethane to obtain the organic phase, dehydrated and evaporated the solvent, the silica gel column was eluted with a mixed solvent of 1:10 volume ratio of ethyl acetate and sherwood oil to obtain C 6 h 5 CH 2 Se(CH 2 ) 4 Cl yellow liquid, C 6 h 5 CH 2 Se(CH 2 ) 4 Cl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| foam stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com