Siloxane bridged trapezoidal polysiloxane, preparation method and application thereof

A technology of siloxane bridge and polysiloxane is applied in the field of siloxane bridge ladder polysiloxane, which can solve the problems of low temperature resistance, low adjustable degree of refractive index, and inconvenient industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0280]

[0281] 1,1,5,5-tetramethoxy-1,5-diphenyl-3,3-diphenyltrisiloxane (274.4g, 0.5mol), 1,1,5,5-tetra Methoxy-1,5-bis(3-methacryloyloxypropyl)-3,3-diphenyltrisiloxane (324.5g, 0.5mol) and tetrahydrofuran (50mL) were placed under mechanical stirring 1. In a three-necked flask with a constant pressure dropping funnel, add DBU (1,8-diazabicyclo[5.4.0]undec-7-ene, 1.0 mL) and water (90 mL) under stirring at room temperature. The reaction was carried out at room temperature for 16 hours, then washed with dilute acid until neutral, concentrated, and purified by vacuum drying to obtain the siloxane bridging ladder polysiloxane with the structure shown above, wherein R 1 = R 2 = phenyl, R 3 = R 4 = 3-methacryloyloxypropyl, A 1 =A 2 =A 3 =A 4 = phenyl, Z 1 = Z 2 = Z 3 = Z 4 = hydrogen, m=1, x / y=1, z=0. The yield of the obtained siloxane bridging ladder polysiloxane random copolymer was 92%.

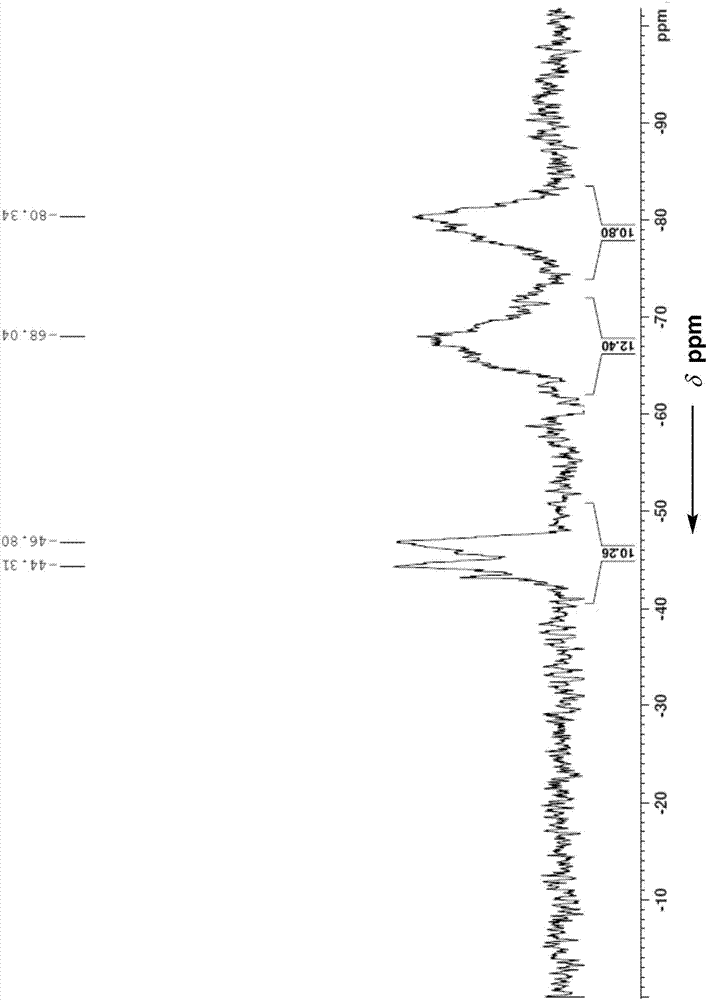

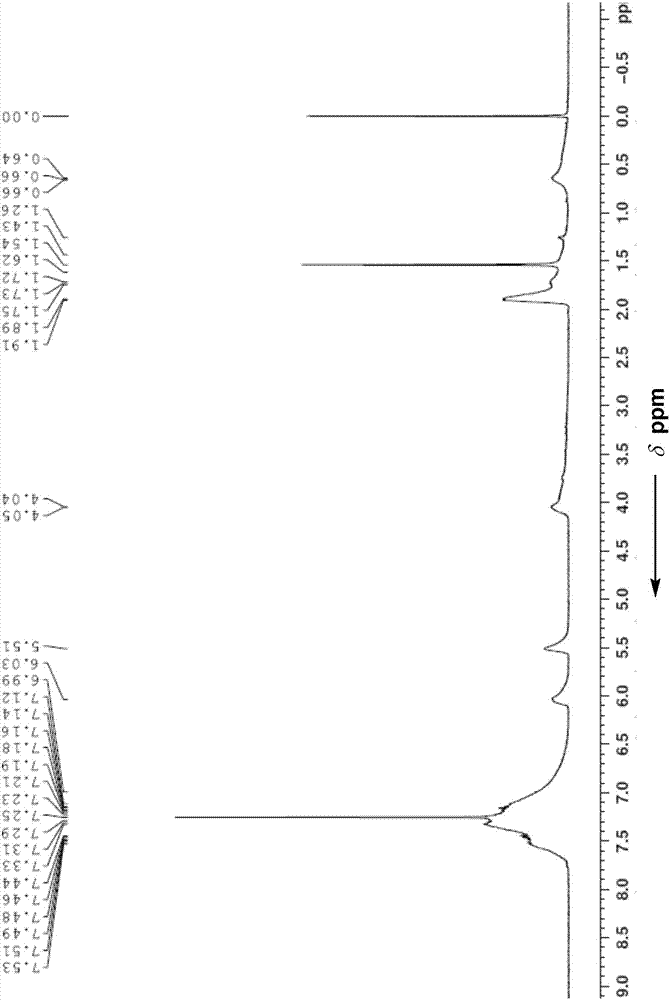

[0282] The resulting siloxane bridging ladder polysiloxane random copolyme...

Embodiment 2

[0284] 1,1,5,5-tetramethoxy-1,5-dimethyl-3,3-diphenyltrisiloxane (212.3g, 0.5mol), 1,1,5,5-tetra Methoxy-1,5-divinyl-3,3-diphenyltrisiloxane (224.3g, 0.5mol) and tetrahydrofuran (50mL) were placed in a three-neck flask with mechanical stirring and a constant pressure dropping funnel , and stirred at room temperature, DBN (1,5-diazabicyclo[4.3.0]non-5-ene, 0.9 mL) and water (90 mL) were added. The reaction was carried out at room temperature for 16 hours, then washed with dilute acid to neutrality, concentrated and vacuum-dried for purification to obtain the siloxane bridging ladder polysiloxane random copolymer of the structure of the aforementioned formula (II), wherein R 1 = R 2 = methyl, R 3 = R 4 = Vinyl, A 1 =A 2 =A 3 =A 4 = phenyl, Z 1 = Z 2 = Z 3 = Z 4 = Hydrogen, m=1, mean value of x+y is 14, x / y=1, z=0.

[0285]

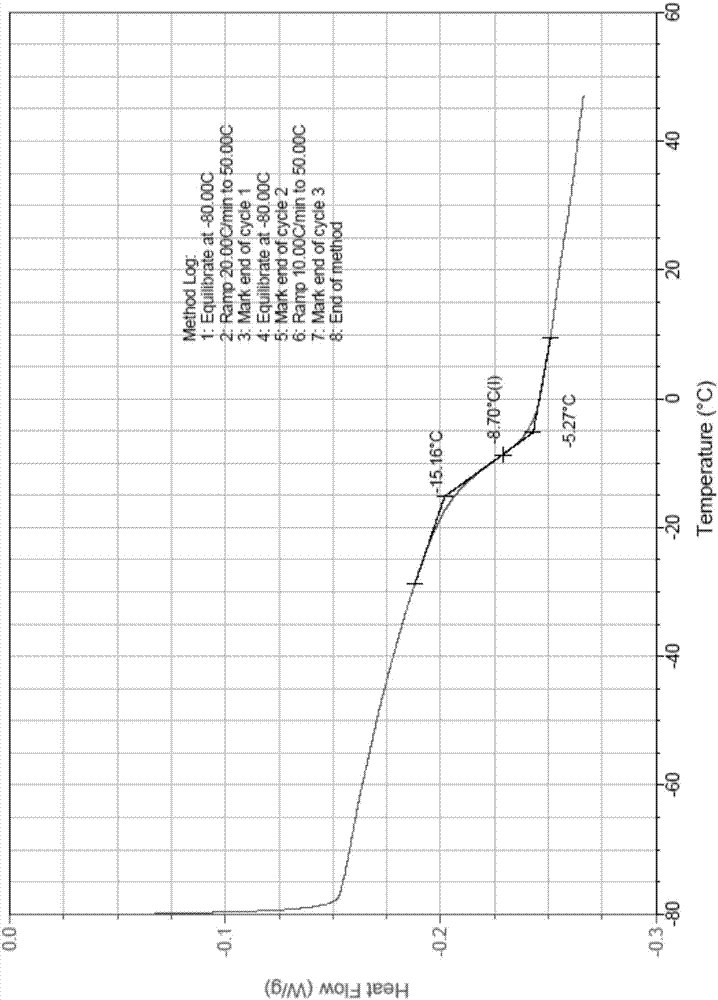

[0286] The obtained siloxane bridging ladder polysiloxane random copolymer was a colorless transparent solid with a yield of 87%. The refrac...

Embodiment 3

[0288] 1,1,5,5-tetramethoxy-1,5-dimethyl-3,3-diphenyltrisiloxane (212.3g, 0.5mol), 1,1,5,5-tetra Methoxy-1,5-divinyl-3,3-diphenyltrisiloxane (224.3g, 0.5mol), 1,1,5,5-tetramethoxy-1,5-diphenyl Diphenyl-3,3-diphenyltrisiloxane (274.4g, 0.5mol) and tetrahydrofuran (50mL) were placed in a three-necked flask with mechanical stirring and a constant pressure dropping funnel, and under stirring at room temperature, potassium tert-butoxide was added (0.2g), water (135mL). The reaction was carried out at room temperature for 16 hours, then washed with dilute acid to neutrality, concentrated and vacuum-dried for purification to obtain the siloxane bridging ladder polysiloxane random copolymer of the structure of the aforementioned formula (II), wherein R 1 = R 2 = methyl, R 3 = R 4 = Vinyl, R 5 = R 6 = phenyl, A 1 =A 2 =A 3 =A 4 =A 5 =A 6 = phenyl, Z 1 = Z 2 = Z 3 = Z 4 =hydrogen, m=1, its molecular weight was analyzed by VPO (vapor pressure osmometer) test, and the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com