High-performance cleanser special for military aircraft engines and preparation method

A military aircraft and engine technology, applied in chemical instruments and methods, surface-active detergent compositions, detergent compositions, etc., can solve the problems of ineffective cleaning, high utilization rate of military engines, and large wear and tear , to enhance oil fluidity, reduce fuel consumption and engine wear, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

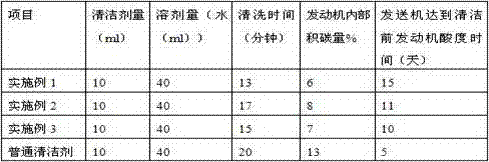

Examples

Embodiment 1

[0024] Each part of chemical supplies of the present embodiment is 20g, and chemical solution is 20ml.

[0025] A special cleaner for military aircraft engines with high performance in this embodiment comprises the following components: 5 parts of higher fatty acid sodium, 4 parts of sodium sulfate, 2 parts of epoxy sodium phosphate, 4 parts of fatty acyl-peptide condensate, benzene 2 parts of triazole, 3 parts of triethanolamine, 4 parts of nano-cerium oxide, 5 parts of monochlorotoluene, and 1 part of dichloromethane and 1 fluorodichloroethane.

[0026] The preparation method of the above-mentioned special cleaning agent for military aircraft engines of the present embodiment, the specific preparation method is as follows:

[0027] (1) Add 5 parts of monochlorotoluene to the reactor, take 5 parts of higher fatty acid sodium, 4 parts of sodium sulfate, 2 parts of epoxy sodium phosphate, 3 parts of sodium citrate, 3 parts of alkanolamide, fatty acyl- Add 4 parts of peptide co...

Embodiment 2

[0031] Each part of chemicals in this embodiment is 100g, and the chemical solution is 100ml.

[0032] A special cleaning agent for military aircraft engines with high performance, including the following components: 4 parts of high fatty acid sodium, 3 parts of sodium sulfate, 3 parts of epoxy sodium phosphate, 5 parts of sodium citrate, 1 part of alkanolamide, fatty acyl - 3 parts of peptide condensate, 3 parts of benzotriazole, 4 parts of triethanolamine, 2 parts of nano silicon oxide, 3 parts of monochlorotoluene.

[0033] The cleaning agent in this embodiment also includes 2 parts of dichloromethane and 2 parts of fluorodichloroethane.

[0034] The preparation method of the above-mentioned special cleaning agent for military aircraft engines of the present embodiment, the specific preparation method is as follows:

[0035] (1) Add 3 parts of monochlorotoluene to the reactor, take 4 parts of higher fatty acid sodium, 3 parts of sodium sulfate, 3 parts of epoxy sodium phos...

Embodiment 3

[0039] Each part of chemicals in this embodiment is 200g, and the chemical solution is 200ml.

[0040] A special cleaning agent for military aircraft engines with high performance, including the following components: 6 parts of sodium fatty acid, 5 parts of sodium sulfate, 1 part of epoxy sodium phosphate, 2 parts of sodium citrate, 4 parts of alkanolamide, fatty acyl - 5 parts of peptide condensate, 1 part of benzotriazole, 3 parts of triethanolamine, 5 parts of nano manganese oxide, 6 parts of monochlorotoluene.

[0041] The cleaning agent in this embodiment also includes 1 part each of dichloromethane and fluorodichloroethane.

[0042] The preparation method of the above-mentioned high-efficiency military aircraft engine special cleaning agent of the present embodiment, the specific preparation method is as follows:

[0043] (1) Add 6 parts of monochlorotoluene into the reactor, take 6 parts of higher fatty acid sodium, 5 parts of sodium sulfate, 1 part of epoxy sodium pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com