Complex enzyme preparation for waste paper making technology and reparation method

A composite enzyme preparation, waste paper making technology, applied in microorganism-based methods, biochemical equipment and methods, and paper making, etc., can solve problems such as inability to adapt, and achieve the effects of reducing pulp strength, reducing cleaning times, and reducing the frequency of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of the composite enzyme preparation of the present invention is as follows: the raw material enzyme preparations are subjected to pretreatment respectively, and then mixed uniformly in proportion, then an appropriate amount of preservative and enzyme protective agent are added, sterilized by a diatomaceous earth filter, and then passed through the determination Enzyme activity, quantitative packaging, and become a product.

[0085] The invention also discloses a papermaking process of waste paper, in which the compound enzyme preparation is continuously added through a metering pump into the hydraulic pulper in waste paper pulping, and the compound enzyme preparation is added according to the standard of 100 grams per ton of dry raw material;

[0086] The components and mass percentages of the compound enzyme preparation are as follows:

[0087] Neutral endo-pectate lyase (enzyme activity ≥ 20000u / ml): 25%-35%;

[0088] Endo-cellulase (enzyme act...

Embodiment 1

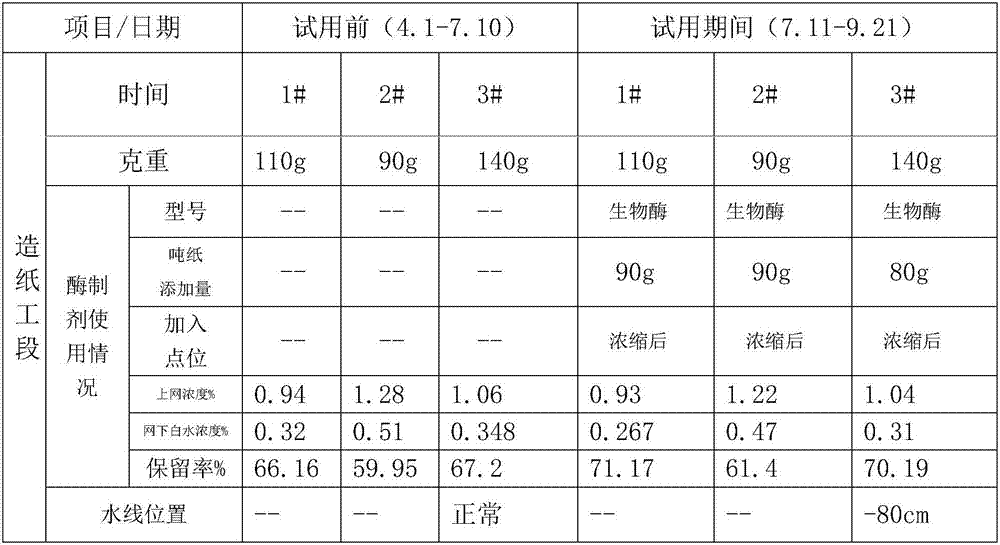

[0102] On July 11, 2017, Dongguan Xufeng Paper Co., Ltd. began to try out the compound enzyme preparation of the present invention. It was added and used at 11:00 am on July 11, and the trial ended on September 21. After more than 60 days of application Test, the specific test data are shown in the table below:

[0103] Table 1 Test data

[0104]

[0105] Among them: due to the failure of the retention aid adding pump during September 12-September 16, the data during the period were not included in the statistics.

[0106] The test data in Table 1 above shows that:

[0107] 1. The concentration of the Internet is reduced, and the load of the network department is reduced;

[0108] 2. The concentration of white water under the screen is reduced, and the retention rate is significantly improved, which is beneficial to sludge reuse;

[0109] 3. The water line is shortened, and the filterability is enhanced, which is beneficial to save steam.

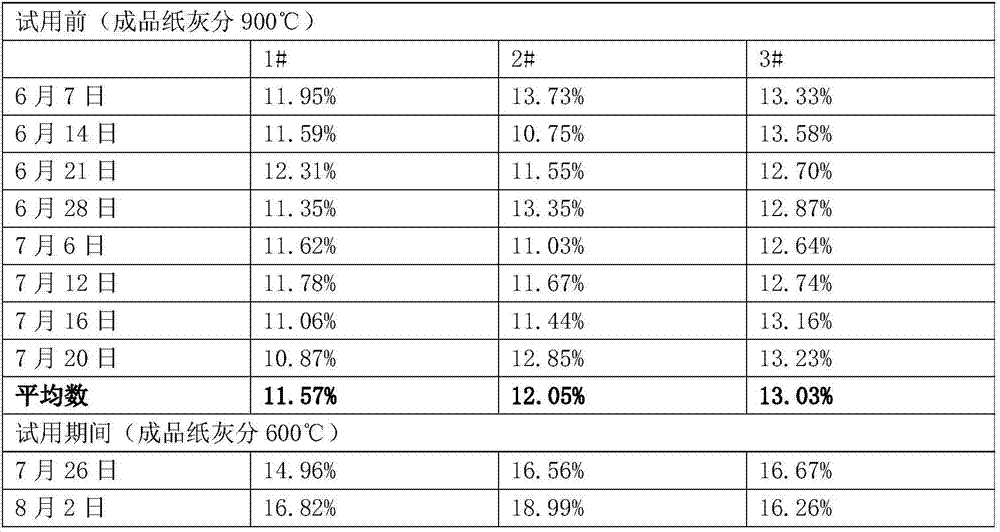

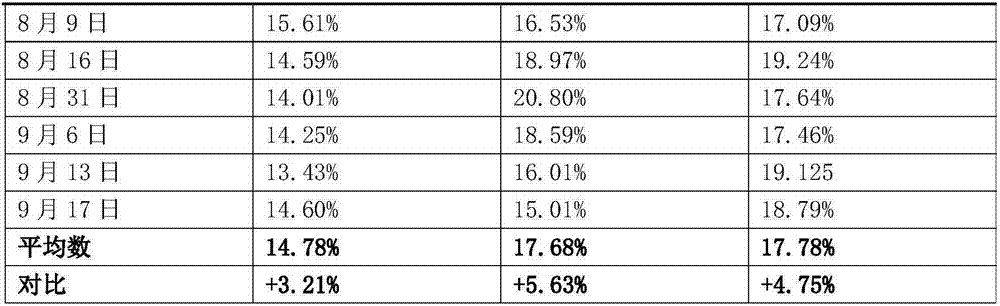

[0110] Table 2 Comparison of ...

Embodiment 2

[0124]On April 28, 2017, Guangzhou Huadu Changxing Paper Co., Ltd. began to try out a series of papermaking enzyme products provided by the present invention ---, as of June 2, after 35 days of continuous application tests, the specific test data are as follows:

[0125] Table 4 Test data comparison

[0126]

[0127] Table 5: Analysis of economic benefits per ton of paper after using papermaking enzymes (estimation)

[0128]

[0129] Note: Papermaking enzymes are calculated at 80,000 yuan / ton (excluding tax).

[0130] From the above data analysis, it can be known that the composite enzyme preparation of the present invention can achieve the following effects:

[0131] 1. The sticky matter is significantly reduced, and the sticky matter in the drying section is significantly reduced, and the paper breakage caused by this is reduced;

[0132] 2. The speed difference of the wire section is significantly reduced, the dehydration of the wire section is obviously improved, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com