Immersed dunaliella salina liquid ultrafiltration system and dunaliella salina liquid concentration method

An ultrafiltration system and immersion technology, applied in the field of salina cultivation, can solve the problems of reducing biomass, increasing the total amount of culture medium, damage and rupture, etc., to increase the concentration of salina, improve harvesting efficiency, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

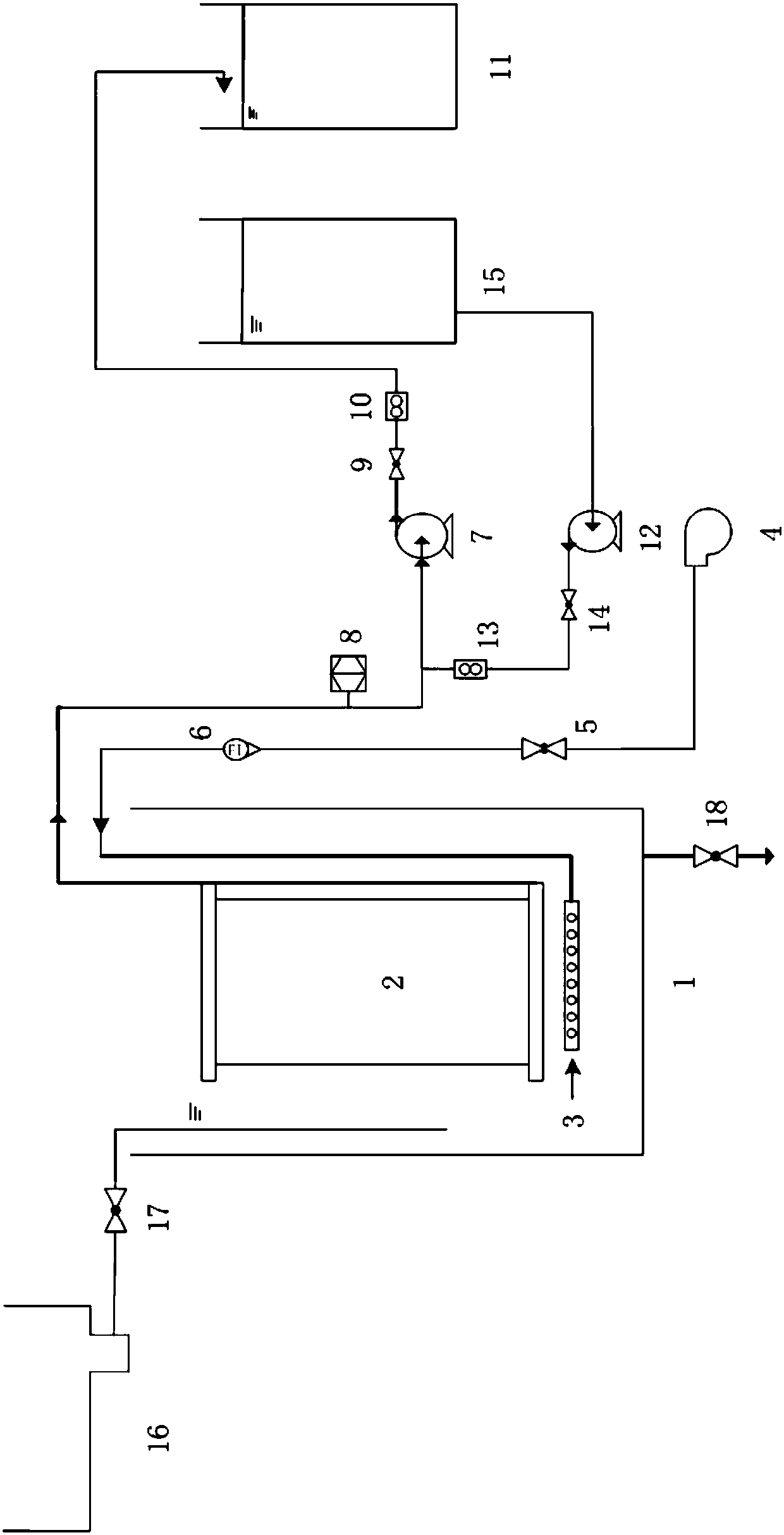

[0039] like figure 1 As shown, a salina liquid submerged ultrafiltration system includes a runway pool 16, a submerged ultrafiltration membrane module 2, a concentration pool 1, a water production system, an aeration system and a backwash system, wherein,

[0040] The liquid outlet below the runway pool 16 communicates with the pipeline of the concentration pool, and the pipeline is provided with a water inlet valve 17;

[0041] The concentration pool 1 is provided with the submerged ultrafiltration membrane module 2 inside. The submerged ultrafiltration membrane in the module adopts a hollow fiber ultrafiltration membrane with a filtration accuracy of 0.03-0.1 μm, and the membrane frame adopts UPVC, ABS, etc. Anti-corrosion materials to prevent corrosion and avoid affecting algae growth;

[0042] The water production system is composed of a water production centrifugal pump 7, a water production regulating valve 9, a water production flowmeter 10, a water production pressure g...

Embodiment 2

[0047] A method for concentrating algae liquid, realizing the concentration of algae liquid through the submerged ultrafiltration system described in embodiment 1, the specific method is as follows:

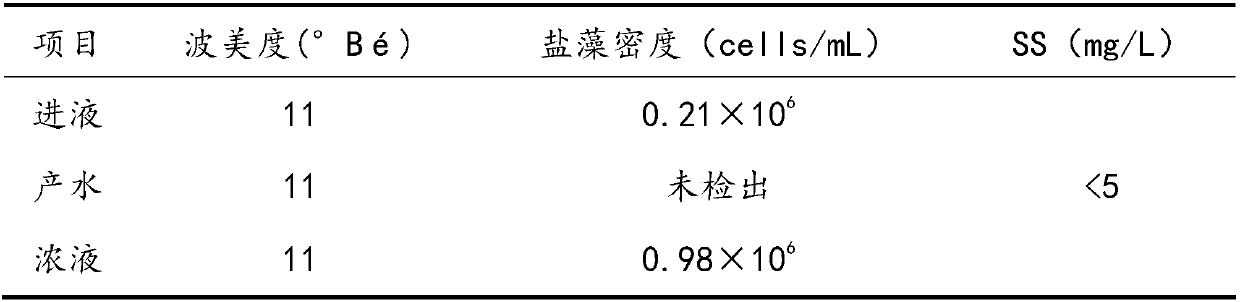

[0048] (1) Salina grows to 5×10 in the raceway pond 16 of 12 ° Bé 5 cells / ml, and then flow into the concentration pool 1 by gravity, and the flow rate can be controlled by the water inlet valve 17 of the runway pool;

[0049] (2) The submerged ultrafiltration membrane is in the concentration pool 1, and the concentration rate of the concentration pool is 2-8. The concentration rate can be controlled by the total amount of culture solution and the average water production in the runway pool entering the concentration pool. When the concentration pool 1 After reaching the 2.0-meter liquid level, the water production system starts to concentrate. After the concentration process starts, the water production regulating valve 9 is opened, and the water production centrifugal pump 7 is...

Embodiment 3

[0055] The design water production is about 80m3 / d.

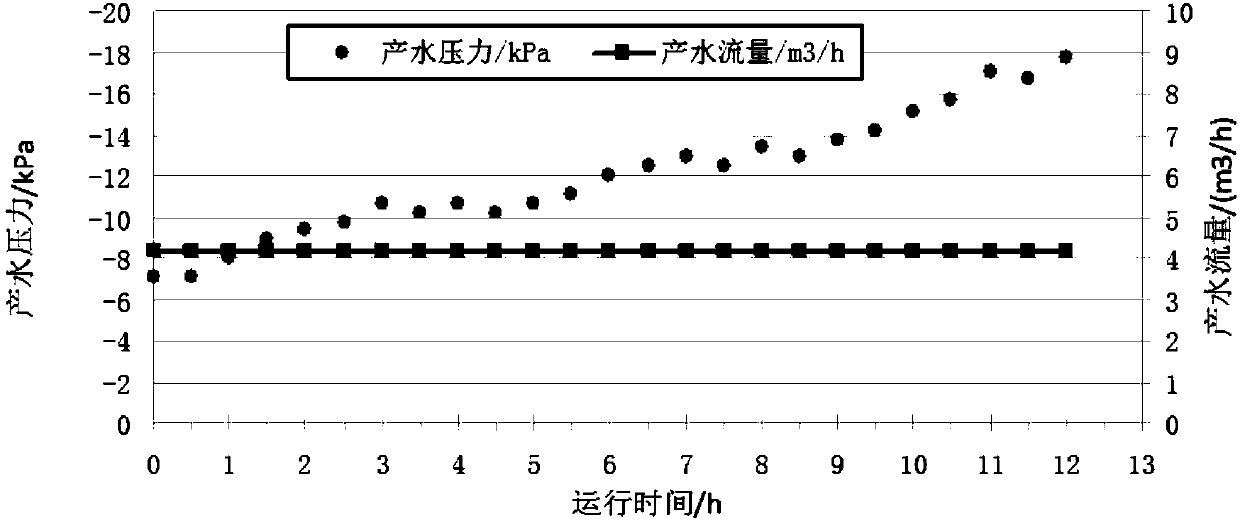

[0056] The designed operating flux is 6.7LMH, and the operating pressure is -5 to -20kPa.

[0057] The system plans to adopt the operation mode of 8 stops and 2 stops, that is, water production for 8 minutes and aeration for 2 minutes.

[0058] The effective volume of the concentration pool is 10m 3 , Concentration tank size: length × width × height = 2.0 × 2.5 × 2.5m, super high 0.5m.

[0059] Adopt 40 curtains 12.5m 2 Curtain ultrafiltration membrane with an average pore size of 0.1μm and a total membrane area of 500m 2 .

[0060] A total of 4 sets of formwork were made, and each set of formwork was composed of 10 curtain films. The water collection pipe, aeration pipe and frame structure are all made of drinking water grade UPVC material. Considering the corrosive characteristics of brine, the main body of the membrane pool adopts PP structure.

[0061] See Example 1 for the specific structure, and Example 2 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com