A preparation method of silane-modified graphene oxide flame-retardant film composite material

A flame-retardant film and silane modification technology, which is applied in the field of preparation of green flame-retardant organosilicon functionalized graphene film composite materials, can solve environmental pollution and other problems, improve physical properties, protect structural stability, and inhibit thermal degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 120 mg graphene oxide and prepare 3 mg.mL -1 Uniformly dispersed aqueous solution, add 120 mg of silane coupling agent KH570 (γ-methacryloxypropyltrimethoxysilane) under stirring, magnetically stir for 1 h, ultrasonic for 10 min, and exhaust the air bubbles under vacuum. The above aqueous solution was reacted in an oven at 90 °C for 24 h under airtight conditions to obtain silanized graphene oxide hydrogel. The hydrogel was dried in air at 40°C for 24 h to form a film to obtain the silane-modified graphene oxide flame-retardant film composite material 1.

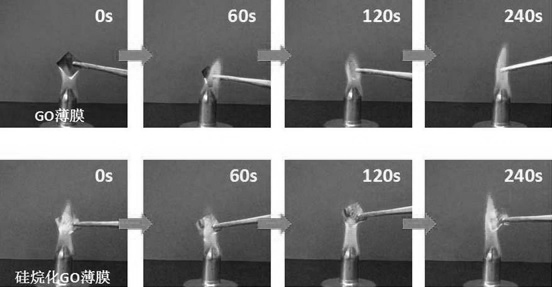

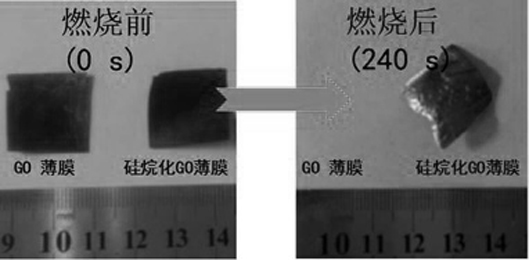

[0023] The obtained silane-modified graphene oxide flame-retardant film composite material 1 has good mechanical properties and can be bent; when the film is exposed to the flame of an alcohol lamp, the surface-modified silane molecules can effectively protect graphene oxide and significantly inhibit the graphite oxide thermal degradation of alkenes. Such as figure 1 As shown, the overall size of the film is b...

Embodiment 2

[0025] Take 120 mg graphene oxide and prepare 8 mg.mL -1 Uniformly dispersed aqueous solution, add 120 mg of silane coupling agent KH570 (γ-methacryloxypropyltrimethoxysilane) under stirring, magnetically stir for 1 h, ultrasonic for 10 min, and exhaust the air bubbles under vacuum. The above aqueous solution was reacted in an oven at 90 °C for 24 h under airtight conditions to obtain silanized graphene oxide hydrogel. The hydrogel was dried in air at 50 °C for 20 h to form a film, and the silane-modified graphene oxide flame-retardant film composite material 2 was obtained.

[0026] The obtained silane-modified graphene oxide flame-retardant film composite material 2 has good mechanical properties and can be bent; when the film is exposed to the flame of an alcohol lamp, the surface-modified silane molecules can effectively protect the graphene oxide and significantly inhibit the graphite oxide Thermal degradation of alkene; the overall size of the sample remains basically u...

Embodiment 3

[0028] Take 200 mg graphene oxide and prepare 1 mg.mL -1 To the uniformly dispersed aqueous solution, add 20 mg of silane coupling agent KH550 (γ-aminopropyltriethoxysilane) under stirring, magnetically stir for 1 h, ultrasonically for 10 min, and exhaust the air bubbles under vacuum. The above aqueous solution was reacted in an oven at 90 °C for 12 h under airtight conditions to obtain silanized graphene oxide hydrogel. The hydrogel was dried in air at 60 °C for 12 h to form a film, and the silane-modified graphene oxide flame-retardant film composite material 3 was obtained.

[0029] The obtained silane-modified graphene oxide flame-retardant film composite material 3 has good mechanical properties and can be bent; when the film is exposed to the flame of an alcohol lamp, the surface-modified silane molecules can effectively protect the graphene oxide and significantly inhibit the graphite oxide Thermal degradation of alkene; the overall size of the sample remains basically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com