Temperature-sensitive hydrogel water retaining agent , and preparation method and application thereof

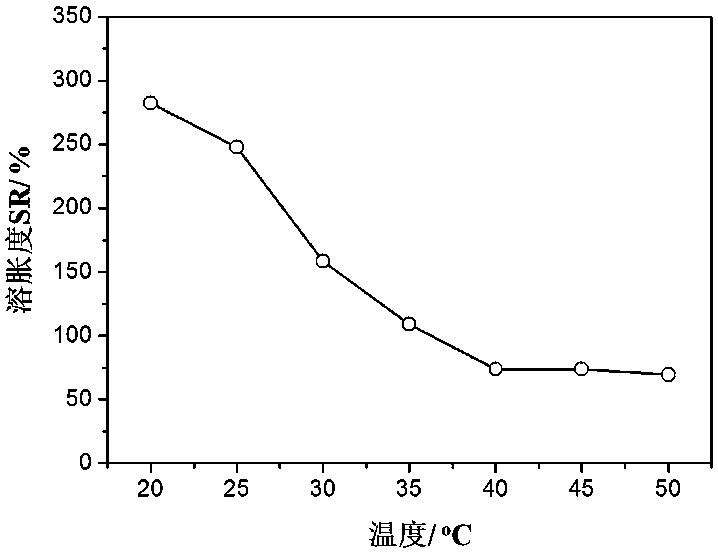

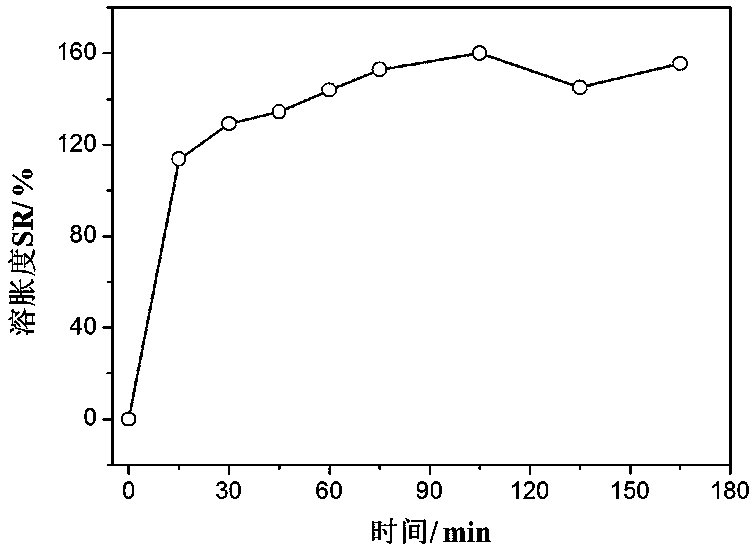

A temperature-sensitive hydrogel and water-retaining agent technology, which can be used in applications, chemical instruments and methods, other chemical processes, etc., can solve the problems of single nature and function of water-retaining agents, difficult to popularize and apply on a large scale, and restricting the application of water-retaining agents. Achieve the effect of being conducive to wide-scale popularization and application, fast water absorption and water release rate, and excellent temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of thermosensitive hydrogel water retaining agent, it comprises the following steps:

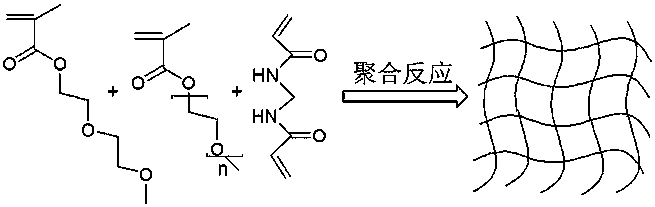

[0026] At 20°C, add 3.5720g of 2-methyl-2-acrylic acid-2-(2-methoxyethoxy)ethyl ester and 0.1800g of polyethylene glycol methyl ether methacrylic acid to a 25mL beaker Esters (average molecular weight: 300), 0.0616g N,N'-methylenebisacrylamide and 15mL deionized water, after stirring for 20min with nitrogen gas, add 0.0200g initiator ammonium persulfate, continue stirring with nitrogen gas for 10min, Add 0.0400g of tetramethylethylenediamine to initiate the reaction, leave it sealed at 20°C, and react for 24 hours to fully polymerize; the reaction process for synthesizing the thermosensitive hydrogel is as follows: figure 1 shown;

[0027] Place the obtained white hydrogel polymer in a 50°C water bath to shrink and release water and pour it out, then add excess deionized water, and after fully swelling at 20°C, place it in ...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of thermosensitive hydrogel water retaining agent, it comprises the following steps:

[0041] At 20°C, add 3.6472g 2-methyl-2-acrylic acid-2-(2-methoxyethoxy)ethyl ester, 0.0600g polyethylene glycol methyl ether methacrylic acid to a 25mL beaker Esters (average molecular weight: 300), 0.0616g N,N'-methylenebisacrylamide and 15mL deionized water, after stirring for 20min with nitrogen gas, add 0.0200g initiator ammonium persulfate, continue stirring with nitrogen gas for 10min, Add 0.0400g of tetramethylethylenediamine to initiate the reaction, leave it sealed at 20°C, and react for 24 hours to fully polymerize;

[0042] Place the obtained white temperature-sensitive hydrogel polymer in a 50°C water bath to make it shrink to release water and pour it out, then add excess deionized water, fully swell at 20°C, place it in a 50°C water bath to make it Shrink again to release water. Repeated washing in this way f...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of thermosensitive hydrogel water retaining agent, it comprises the following steps:

[0046] At 20°C, 3.6848g of 2-methyl-2-propenoic acid-2-(2-methoxyethoxy)ethyl ester, 0.0616g of N,N'-methylenebis Acrylamide and 15mL deionized water were stirred with nitrogen gas for 20 minutes, then 0.0200 g of initiator ammonium persulfate was added, and after nitrogen gas flow was continued for 10 minutes, 0.0400 g of tetramethylethylenediamine was added to initiate the reaction. Seal and stand still, react for 24h to make it fully polymerized;

[0047] Place the obtained white temperature-sensitive hydrogel polymer in a 50°C water bath to make it shrink to release water and pour it out, then add excess deionized water, fully swell at 20°C, place it in a 50°C water bath to make it Shrink again to release water. Repeated washing in this way for 3 to 5 times to remove impurities such as incompletely reacted monomers and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com