Modified dicyclopentadiene hydrogenated petroleum resin and preparation method thereof

A technology for hydrogenating petroleum resin and dicyclopentadiene, which is applied in the field of modified dicyclopentadiene hydrogenated petroleum resin and its preparation, can solve problems such as the limitation of use range, achieves promotion of mixing and dispersion, improvement of thermal stability, good compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through specific embodiments.

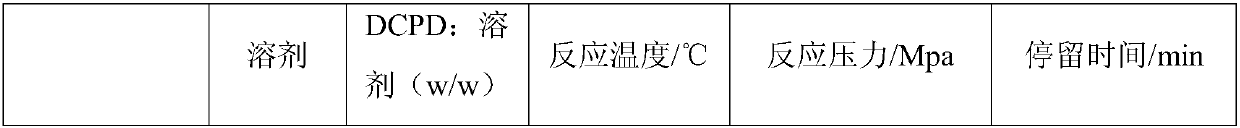

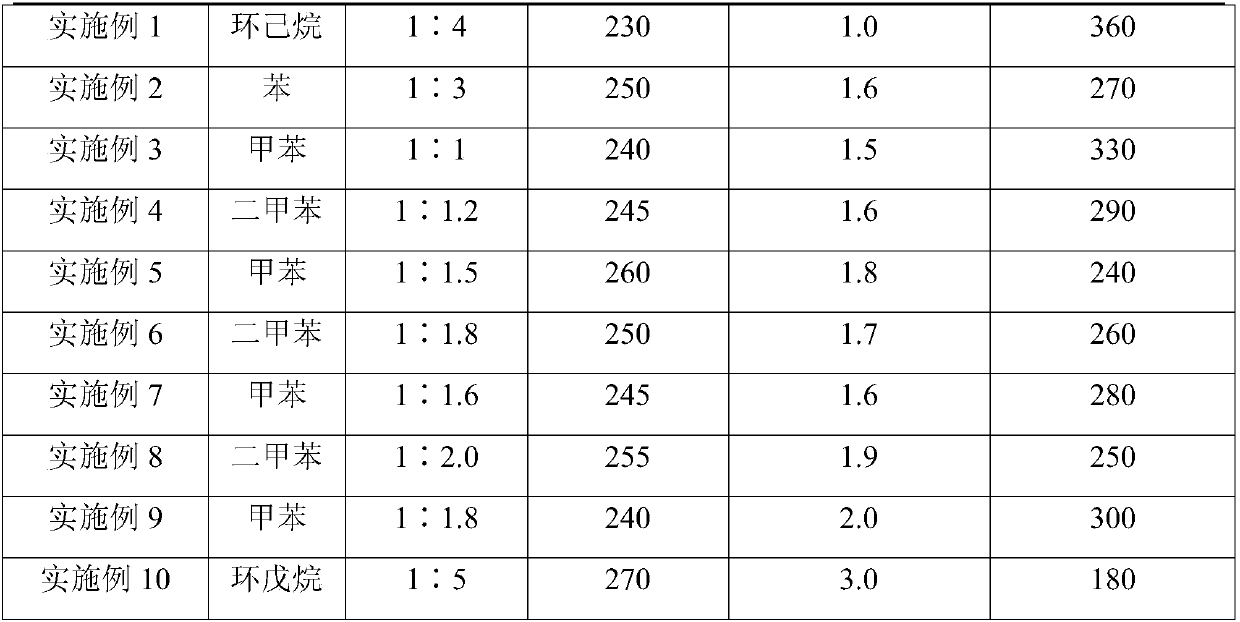

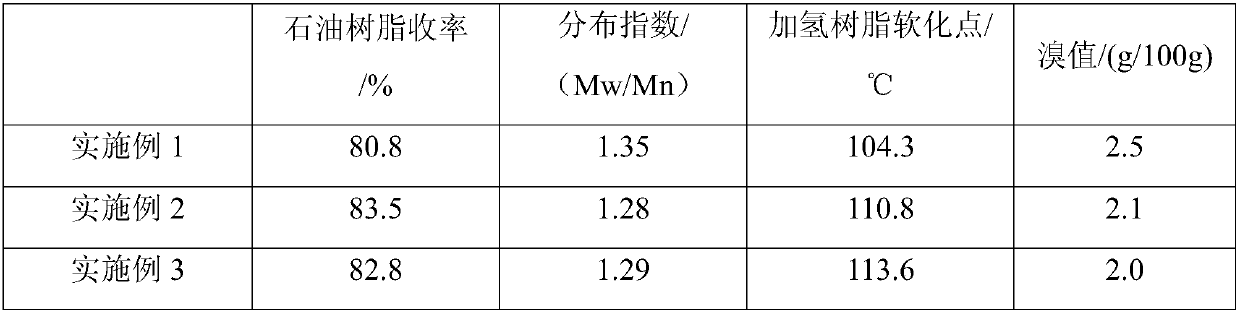

[0017] Embodiment 1~10 carries out the preparation of hydrogenated petroleum resin according to the following steps: reaction raw material is the material rich in DCPD, and its main composition is shown in Table 1, and each step process condition is shown in Table 2 (step 1), table 3 (step 1) and Table 3 (step 2). After the reaction, the resin samples were weighed and analyzed for various indicators (softening point, molecular weight distribution and bromine value, etc.). The results are shown in Table 5. The molecular weight distribution index (M) of the resin product was determined by gel chromatography w / M n ), the softening point was analyzed by the ring and ball method GB / 2294, and the bromine value was analyzed by the iodometric method (SWB2301-62).

[0018] 1) After the DCPD raw material is mixed with the organic solvent, it enters the reactor, and conducts thermal polymeriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com