Soil conditioner drying device with sterilization function

A soil conditioner and drying device technology, applied in drying, dryer, heating device and other directions, can solve the problems of incomplete drying process, affecting soil conditioner, and poor drying efficiency, so as to improve the drying efficiency. Efficiency and quality, increased contact area, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

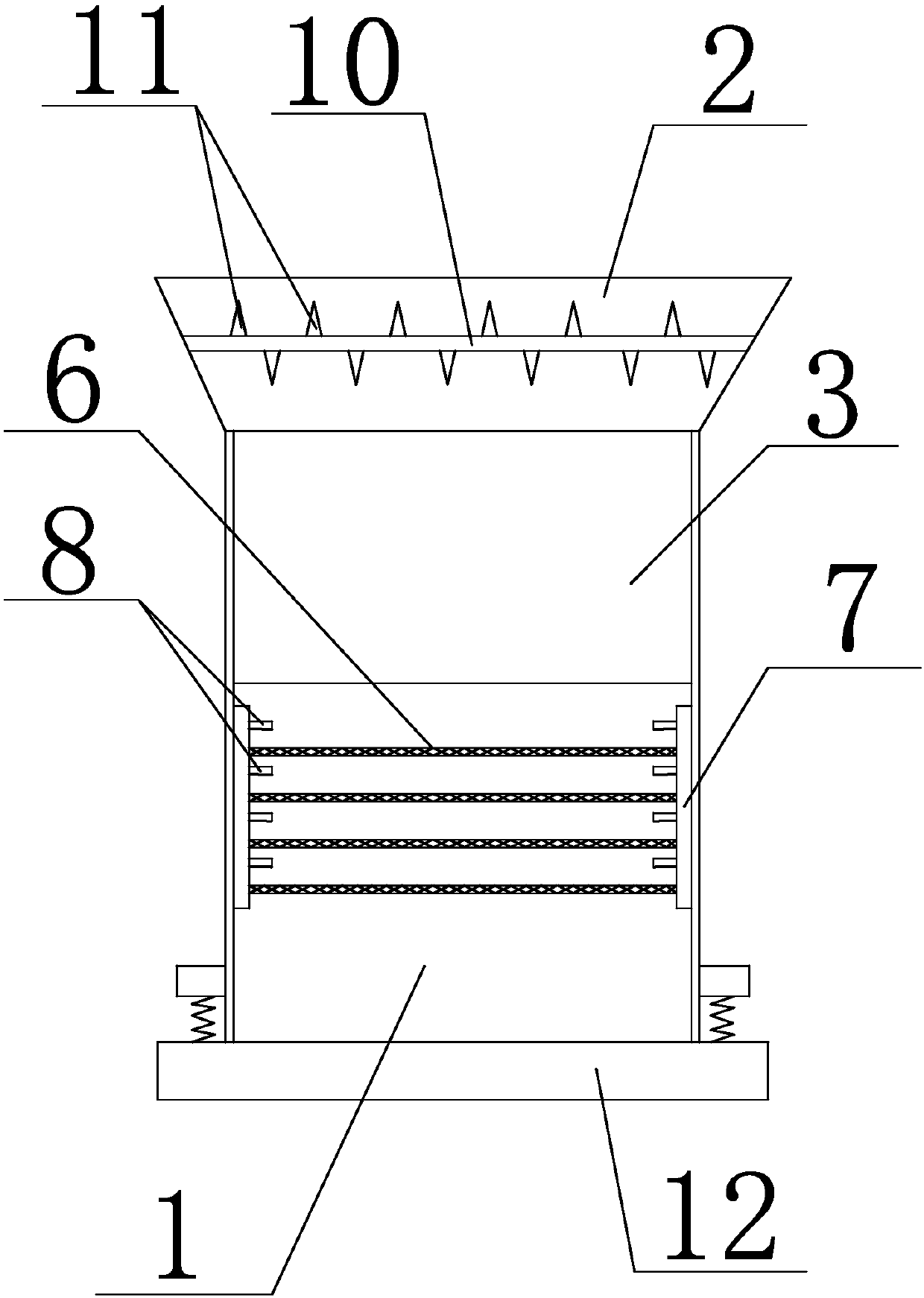

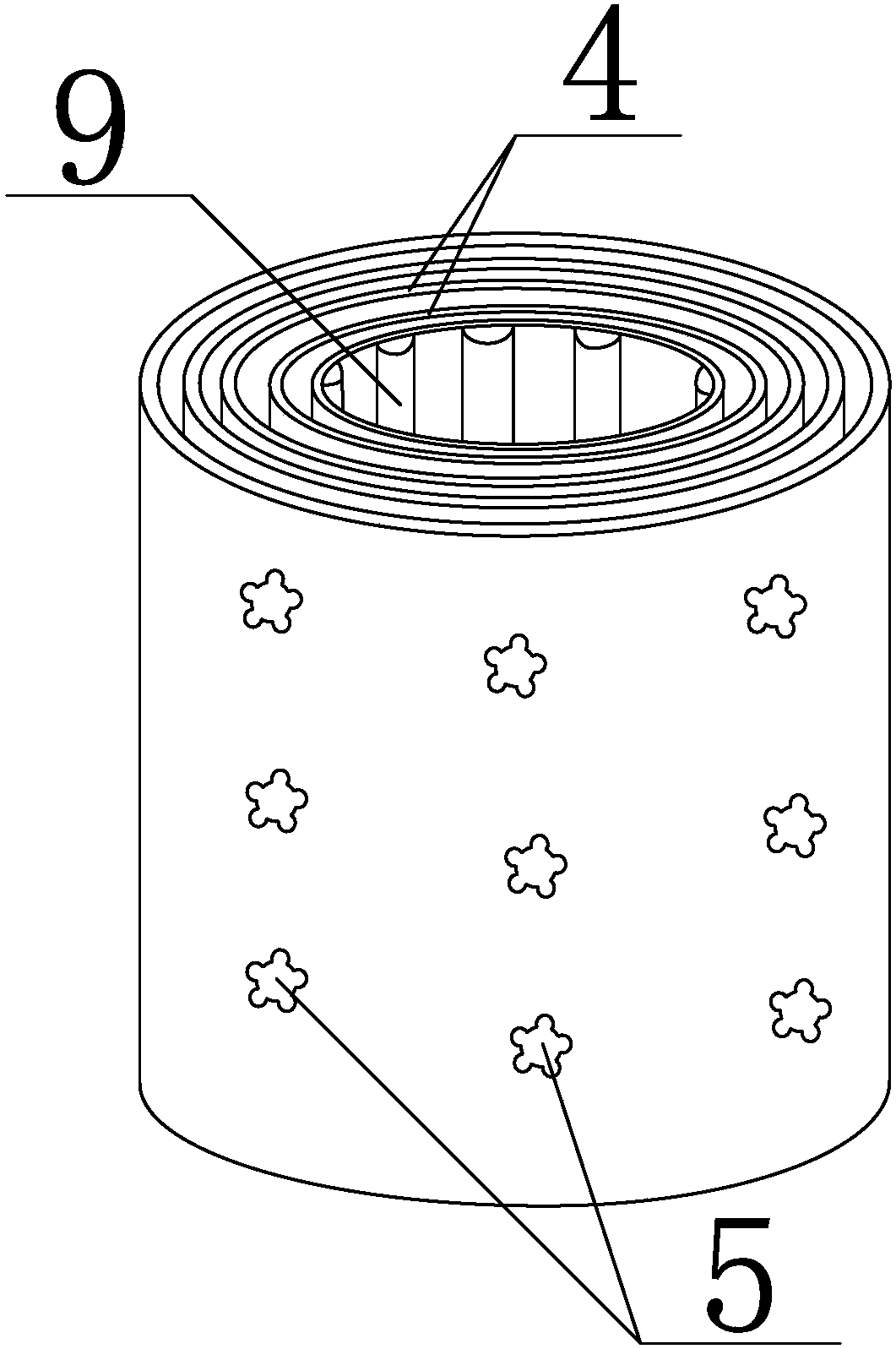

[0022] Such as figure 1 and figure 2 As shown, the soil conditioner drying device with sterilization function of the present invention includes a drying cylinder 1, the top of the drying cylinder 1 is open and is provided with a hopper 2, and a drying cylinder 1 is provided below the hopper 2. Drying device 3, the drying device 3 includes a plurality of cylindrical drying heating plates 4 with openings at both ends of the upper and lower ends sequentially sleeved from the inside to the outside, and the diameter of the drying heating plates 4 gradually increases from the inside to the outside, The drying heating plate 4 is connected to the power supply; the drying heating plate 4 is provided with convection holes 5, and the drying cylinder 1 below the drying device 3 is provided with a plurality of vibrating screens 6 from top to bottom. A plurality of ultraviolet lamps 7 are sequentially arranged on the inner wall of the surrounding drying cylinder 1 along the circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com