Integrated packaging structure of IGBT chip and phase-transformation soaking plate

An integrated packaging and vapor chamber technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices. The effect of enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below.

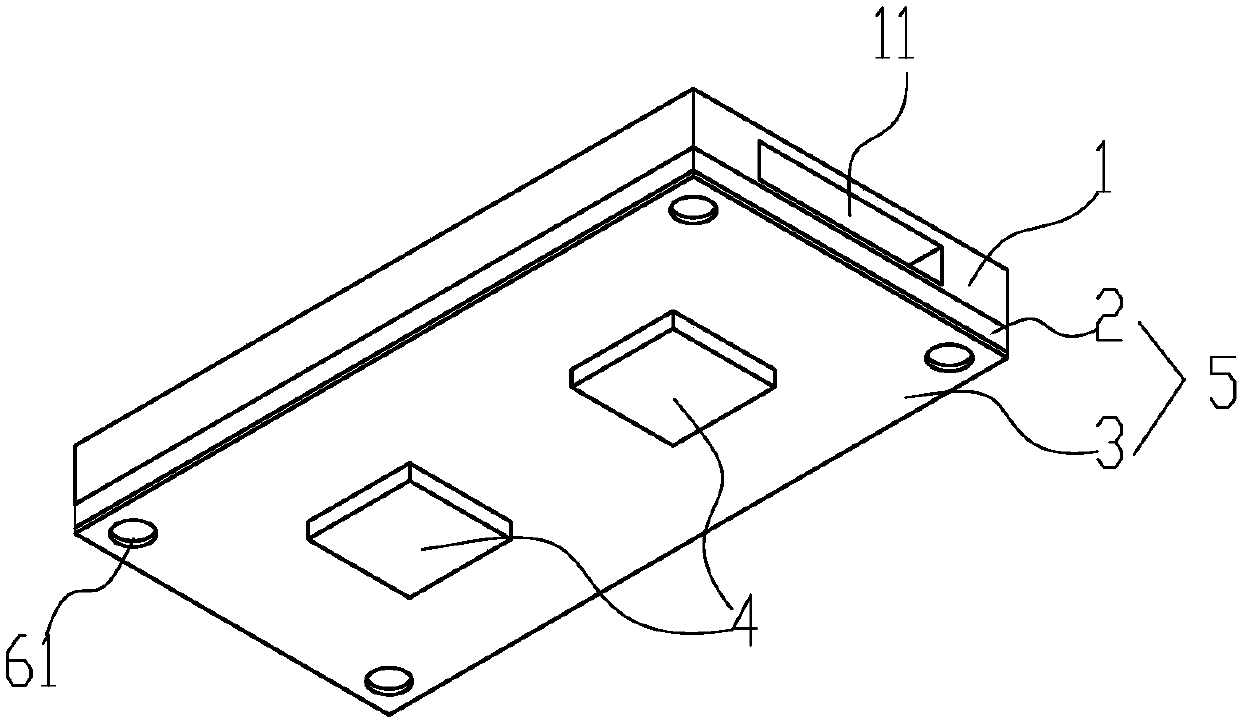

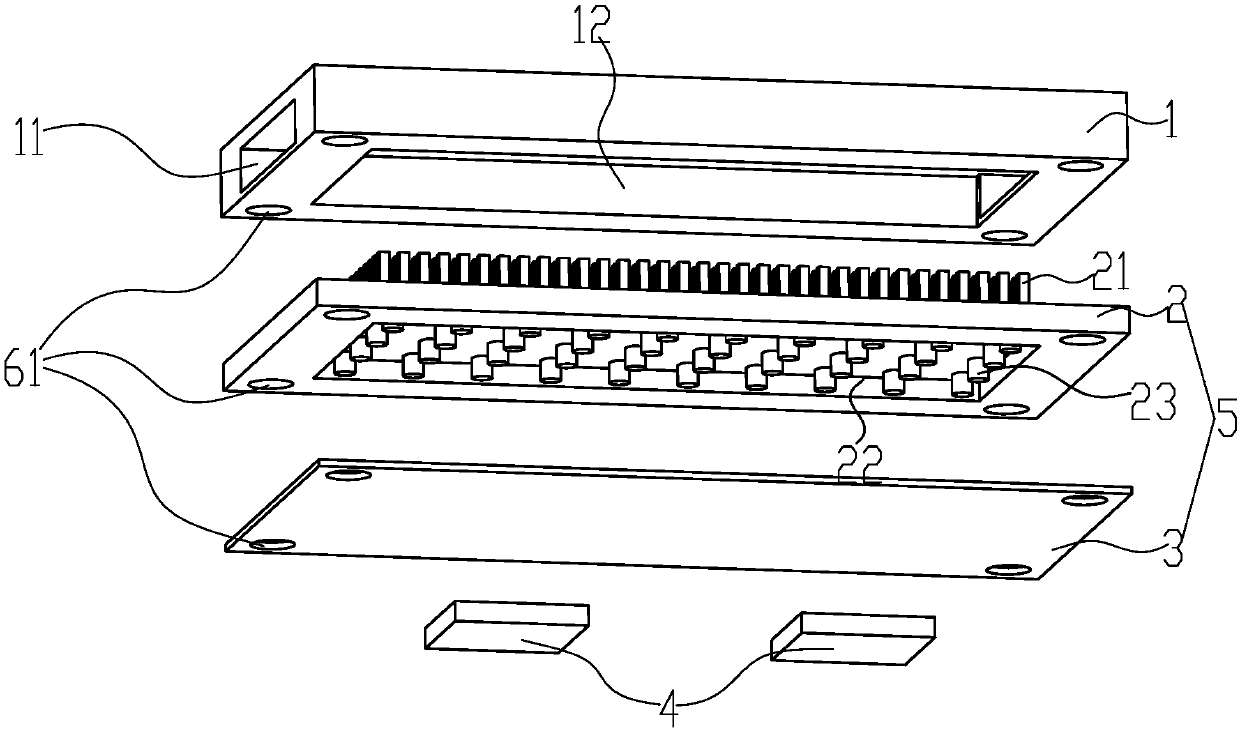

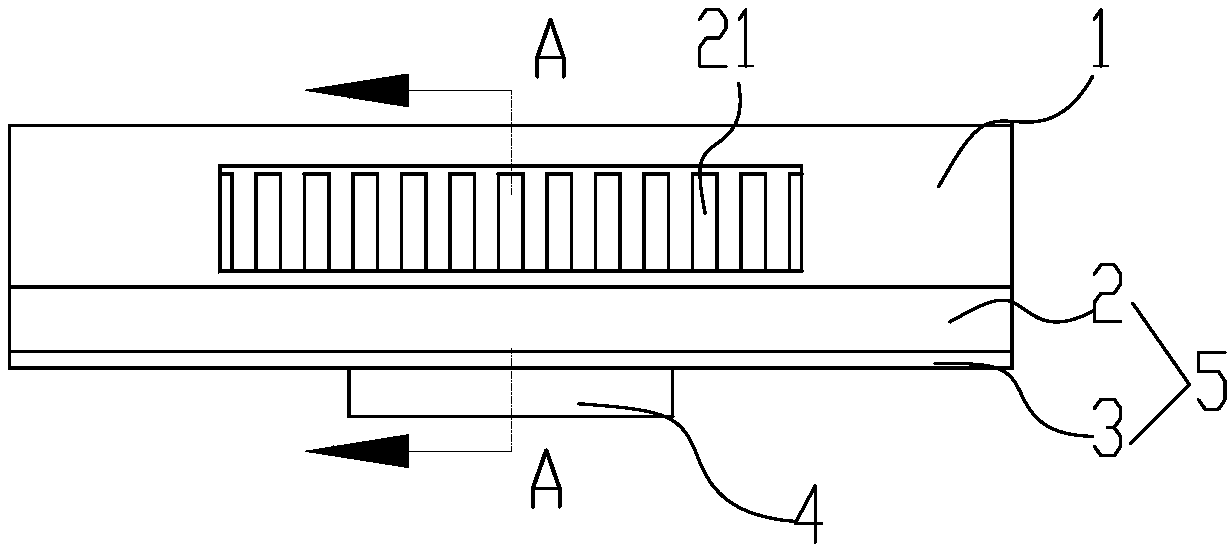

[0044] Such as Figure 1 to Figure 4 As shown, the integrated packaging structure of the IGBT chip and the phase change chamber includes the end cover 1, the upper shell plate 2, the bottom plate 3 and the IGBT chip 4 that are sequentially fixed together. The IGBT chip 4 is welded on the bottom surface of the bottom plate 3, and the upper The side of the shell plate 2 close to the end cover 1 is provided with several columnar fins 21, the end cover 1 and the upper shell plate 2 enclose a heat exchange space for heat exchange, and several columnar fins 21 are located in the heat exchange space, The heat exchange space is provided with at least one coolant inlet and outlet 11, and the upper shell plate 2 is provided with several support columns 23 on the side close to the bottom plate 3, and the upper shell plate 2 and the bottom plate 3 form a closed cavity of the chamber, and A support column 23 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com