Water quality improver and preparation method thereof

A technology of water quality improver and adsorbent, which is applied in the field of water quality improver and its preparation, which can solve the problems of insufficient dissolved oxygen, increase of water body nutrition, economic loss, etc., and achieve the effects of significant removal, increased transparency, and increased dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

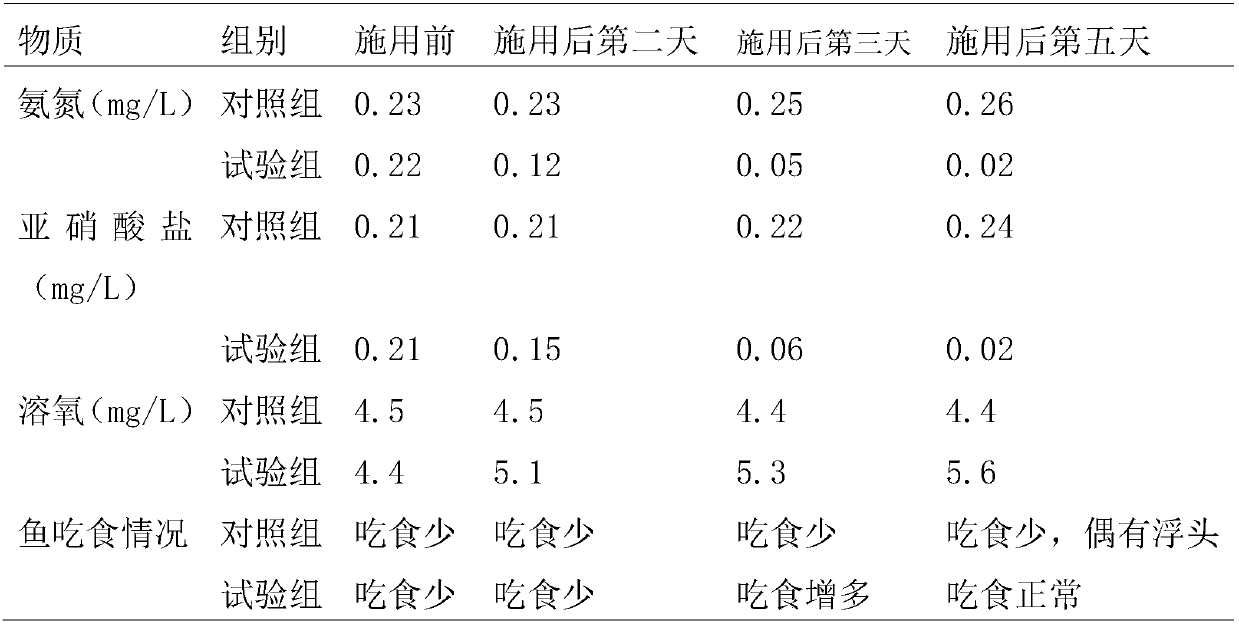

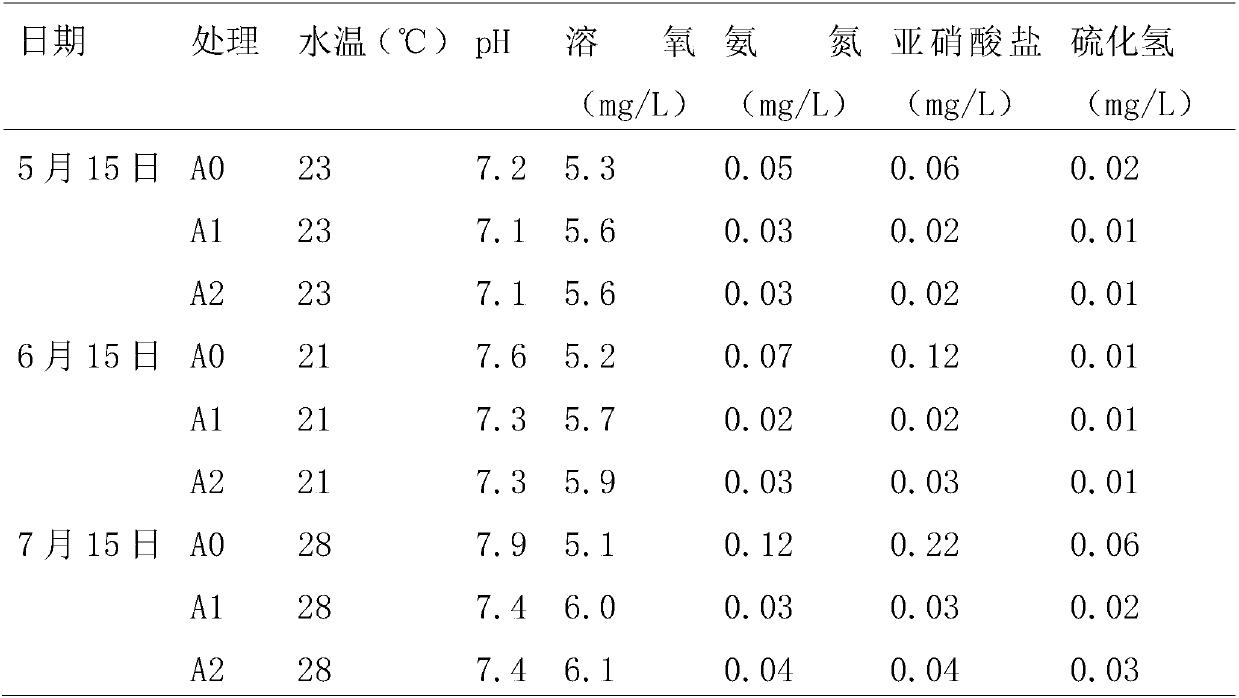

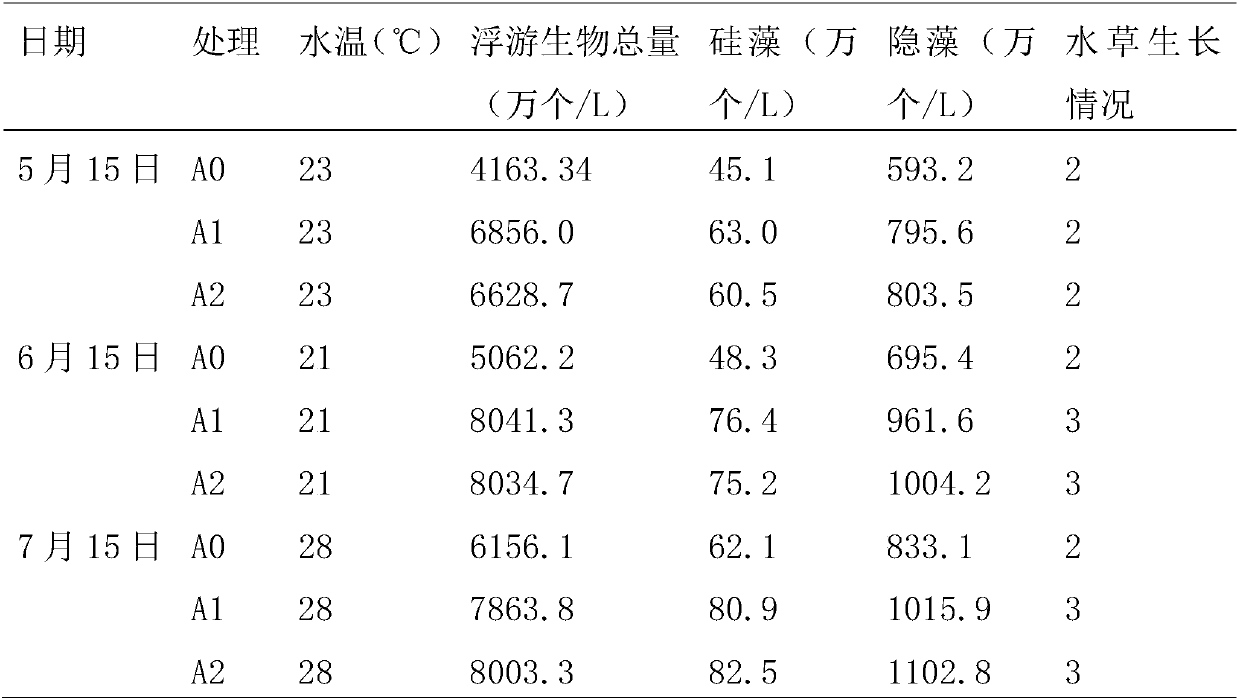

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of water quality improving agent, comprises the following steps:

[0032]Take aluminum sulfate, sodium phate, sodium metasilicate, zeolite powder and adsorbent, and mix 30 to 45 parts of aluminum sulfate, 5 to 10 parts of sodium humate, and 5 to 10 parts of sodium metasilicate in parts by weight. 20-30 parts of zeolite powder and 5-40 parts of adsorbent. Mix the above components uniformly to obtain the water quality improver.

[0033] Specifically, under dry conditions, 30-45 parts by weight of aluminum sulfate, 5-10 parts of sodium humate, 5-10 parts of sodium metasilicate, 20-30 parts of zeolite powder and 5-40 parts of adsorbent Add it to the reaction kettle at one time, stir and mix evenly under the condition of 5°C-45°C to obtain a water quality improver, and stir at a stirring speed of 40-80 revolutions per minute for 20-40 minutes and mix evenly. For reaction temperature, generally get final produc...

Embodiment 1

[0037] A water quality improver comprises the following components in parts by weight: 30 parts of aluminum potassium sulfate, 5 parts of sodium humate, 5 parts of sodium metasilicate, 20 parts of zeolite powder, 20 parts of activated carbon and 20 parts of bentonite.

[0038] The water quality improver of the present embodiment, its preparation method is as follows:

[0039] Under dry conditions, add 30 parts by weight of aluminum potassium sulfate, 5 parts of sodium humate, 5 parts of sodium metasilicate, 20 parts of zeolite powder, 20 parts of activated carbon and 20 parts of bentonite into the reaction kettle at one time. Under the conditions, the mixture was stirred for 40 minutes at a stirring speed of 40 rpm to obtain a water quality improver.

Embodiment 2

[0041] A water quality improver, comprising the following components in parts by weight: 25 parts of aluminum potassium sulfate, 20 parts of aluminum ammonium sulfate, 10 parts of sodium humate, 10 parts of sodium metasilicate, 30 parts of modified zeolite powder and modified 5 parts of activated carbon.

[0042] The water quality improver of the present embodiment, its preparation method is as follows:

[0043] Under dry conditions, add 25 parts by weight of aluminum potassium sulfate, 20 parts of aluminum ammonium sulfate, 10 parts of sodium humate, 10 parts of sodium metasilicate, 30 parts of modified zeolite powder and 5 parts of modified activated carbon into the reactor at one time In the process, under the condition of 45° C., stir with a stirring speed of 80 revolutions per minute for 20 minutes and mix evenly to obtain a water quality improver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com