System and method for separating and recycling propylene in epoxypropane production process with HPPO (Hydrogen Peroxide Direct Oxidation Process) method

A technology for the separation and recovery of propylene oxide, which is applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of large power consumption, large compressor operating load, and many separation equipment, so as to reduce operating costs and equipment investment and improve Equipment connection and operation process, the effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

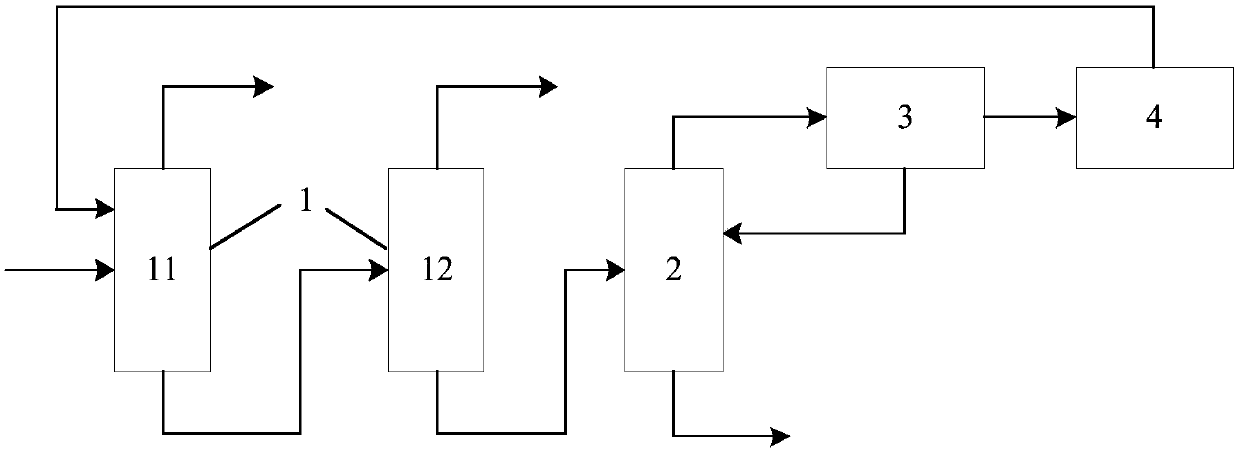

[0043] This embodiment provides a separation and recovery system for propylene in the process of producing propylene oxide by the HPPO method, and its equipment connection schematic diagram is as follows figure 1 As shown, the system includes a rectification tower 1, a packed tower 2, a subcooler 3 and a compressor 4; wherein, the bottom outlet of the rectification tower 1 is connected to the feed port of the packed tower 2, and the packing The top discharge port of tower 2 is connected with the feed port of subcooler 3, and the gas phase discharge port of described subcooler 3 is connected with the feed port of compressor 4, and the liquid phase discharge port of described subcooler 3 The port is connected with the reflux port of the packed tower 2, and the discharge port of the compressor 4 is connected with the feed port of the rectifying tower 1.

[0044] The rectification tower 1 comprises a first rectification tower 11 and a second rectification tower 12, the bottom outl...

Embodiment 2

[0047] This embodiment provides a separation and recovery system for propylene in the process of producing propylene oxide by the HPPO method, the system includes a rectification tower 1, a packed tower 2, a subcooler 3 and a compressor 4; wherein the rectification tower 1 The bottom discharge port is connected with the feed port of the packed tower 2, the top discharge port of the packed tower 2 is connected with the feed port of the subcooler 3, and the gas phase discharge port of the subcooler 3 is connected with the compressor 4 is connected to the feed port, the liquid phase discharge port of the subcooler 3 is connected to the reflux port of the packed tower 2, and the discharge port of the compressor 4 is connected to the feed port of the rectification tower 1.

[0048] The rectification tower 1 comprises a first rectification tower 11 and a second rectification tower 12, the bottom outlet of the first rectification tower 11 is connected with the feed inlet of the second...

Embodiment 3

[0051] This embodiment provides a separation and recovery system for propylene in the process of producing propylene oxide by the HPPO method, the system includes a rectification tower 1, a packed tower 2, a subcooler 3 and a compressor 4; wherein the rectification tower 1 The bottom discharge port is connected with the feed port of the packed tower 2, the top discharge port of the packed tower 2 is connected with the feed port of the subcooler 3, and the gas phase discharge port of the subcooler 3 is connected with the compressor 4 is connected to the feed port, the liquid phase discharge port of the subcooler 3 is connected to the reflux port of the packed tower 2, and the discharge port of the compressor 4 is connected to the feed port of the rectifying tower 1, that is, the There is only one rectifying tower 1 mentioned above.

[0052] The packed column 2 and the compressor 4 are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com