Method for synthetizing 2-trifluoromethyl oxazole compound

A technology of trifluoromethyloxazole and a synthetic method, applied in directions such as organic chemistry, can solve the problems of unobtainable raw materials, harsh conditions, complicated steps and the like, and achieves the effects of good adaptability, easy operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

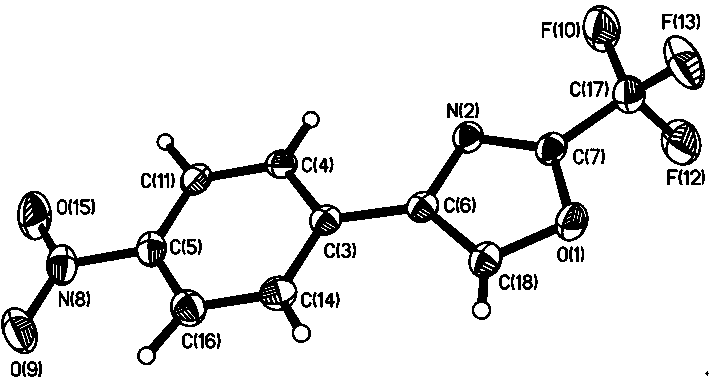

Image

Examples

Embodiment 1

[0020] Put a polytetrafluoroethylene magnet in a 25 mL reaction tube, add 1.0 mmol acetophenone O-acetyl oxime, 2.0 mmol trifluoroacetic anhydride, 1.0 mmol tellurium powder, 0.2 mmol iodine and 3.0 mL toluene, 120 °C After stirring and reacting in a closed system for 4 h, the resulting reaction solution was extracted three times with ethyl acetate, the organic phases were combined, washed with water and then evaporated to remove the organic solvent; the obtained crude product was purified by silica gel column chromatography using n-pentane as the eluent. 4-Phenyl-2-(trifluoromethyl)oxazole was isolated (95% yield). 1 H NMR (400 MHz, CDCl 3 ) δ 8.03 (s, 1H), 7.79 (d, J = 7.6 Hz, 2H), 7.44(dt, J = 22.5, 7.0 Hz, 3H). 19 F NMR (376 MHz, CDCl 3 ) δ -65.9 (s, 3F). 13 C NMR (101 MHz, CDCl 3 ) δ 150.9 (q, J = 44.0 Hz), 142.1 (s), 135.4 (q, J = 1.2 Hz), 129.2 (s), 129.1 (s), 128.9 (s), 125.8 (s), 116.5 (q, J = 270.7 Hz). GC-MS m / z 213 (M + ).

Embodiment 2

[0022] Put a PTFE magnet in a 25 mL reaction tube, add 1.0 mmol 4-methylacetophenone O-acetyl oxime, 2.0 mmol trifluoroacetic anhydride, 1.0 mmol tellurium powder, 0.2 mmol iodine and 3.0 mL Toluene, stirred and reacted in a closed system at 120°C for 4 h, the resulting reaction solution was extracted three times with ethyl acetate, the organic phases were combined, washed with water, and then rotary evaporated to remove the organic solvent; the obtained crude product used n-pentane as the eluent, passed Silica gel column chromatography gave 4-(p-tolyl)-2-(trifluoromethyl)oxazole (98% yield). 1 H NMR (400 MHz, CDCl 3 ) δ 8.00 (s, 1H), 7.68 (d, J = 8.2 Hz, 2H),7.28 (d, J = 8.3 Hz, 2H), 2.42 (s, 3H). 19 F NMR (376 MHz, CDCl 3 ) δ -65.8 (s,3F). 13 C NMR (101 MHz, CDCl 3 ) δ 150.9 (q, J = 43.9 Hz), 142.1 (s), 139.1 (s), 134.9 (q, J = 1.2 Hz), 129.6 (s), 126.40 (s), 125.7 (s), 116.5 (q, J = 270.6Hz), 21.3 (s).. GC-MS m / z 227 (M + ).

Embodiment 3

[0024] Put a polytetrafluoroethylene magnet in a 25 mL reaction tube, add 1.0 mmol 4-methylthioacetophenone O-acetyl oxime, 2.0 mmol trifluoroacetic anhydride, 1.0 mmol tellurium powder, 0.2 mmol iodine and 3.0 mL of toluene, stirred and reacted in a closed system at 120°C for 4 h, the resulting reaction solution was extracted three times with ethyl acetate, the organic phases were combined, washed with water and then evaporated to remove the organic solvent; the obtained crude product was obtained with n-pentane as eluent, 4-(p-Methylthiobenzene)-2-(trifluoromethyl)oxazole was obtained by silica gel column chromatography (yield 73%). 1 H NMR (400 MHz, CDCl 3 ) δ 8.02 (s, 1H), 7.82 – 7.63 (m, 2H), 7.32 (d, J = 8.2 Hz, 2H), 2.54 (s, 3H). 19 F NMR (376 MHz, CDCl 3 ) δ -65.8 (s,3F). 13 C NMR (101 MHz, CDCl 3 ) δ 150.9 (q, J = 44.2 Hz), 141.7 (s), 140.0 (s), 135.1 (d, J = 0.9 Hz), 126.50\ (s), 126.2 (s), 125.8 (s), 116.5 (q, J = 270.6Hz), 15.5 (s). GC-MS m / z 259 (M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com