Waterproof finishing solution for polyamide fiber fabric and padding method of polyamide fiber fabric

A polyamide fiber and waterproof finishing technology, which is applied in the field of textile manufacturing, can solve the problems of not being able to find a waterproof method for polyamide fiber fabrics, and achieve the effects of avoiding delamination of the flame-retardant coating, significant effect, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

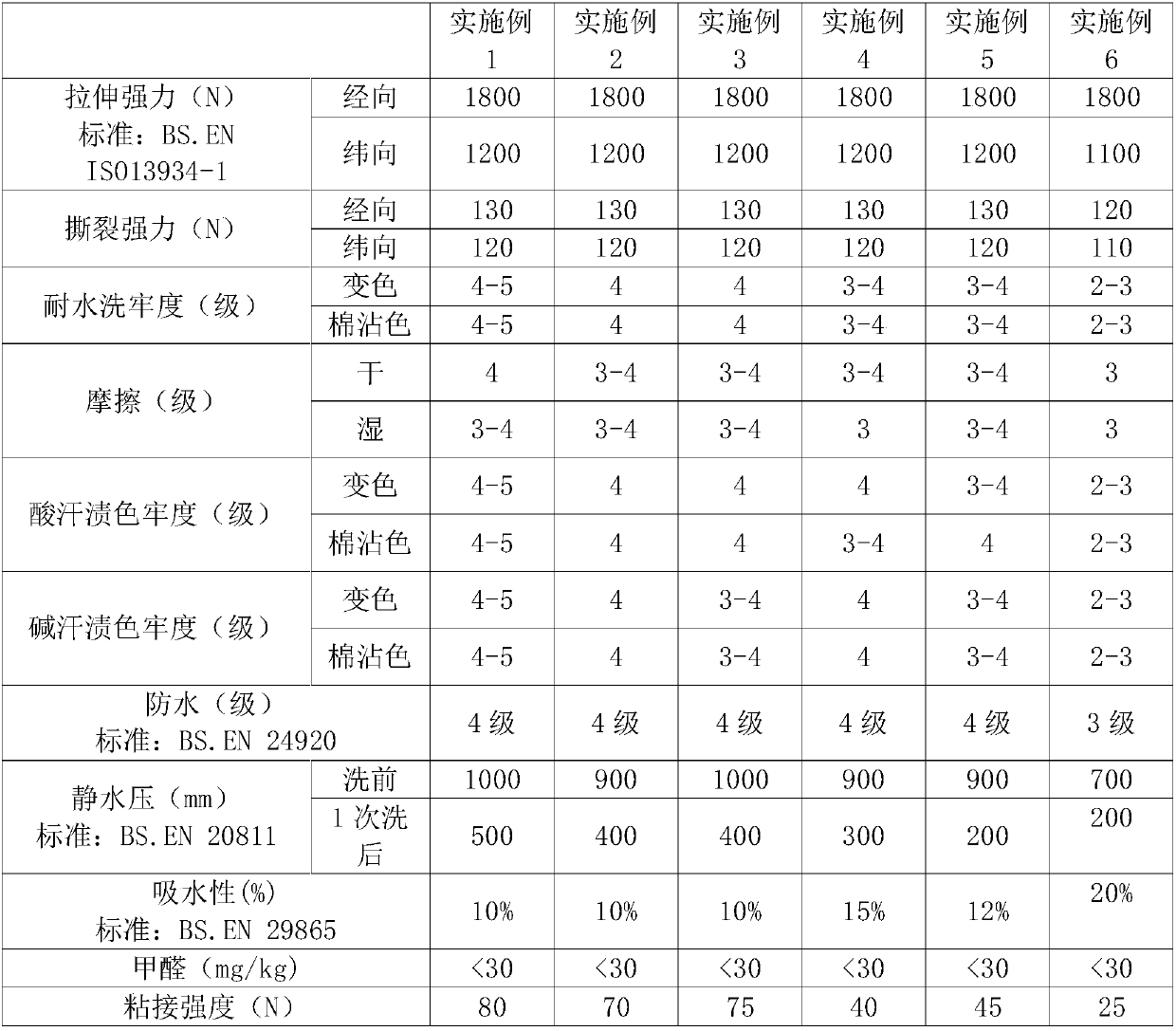

Examples

Embodiment 1

[0025] A polyamide fiber fabric, the specific preparation process includes: gray cloth→cloth turning→cold pad-batch→scouring→setting→dyeing→printing→baking→steaming→soaping→color fixing→waterproof tentering→ Calendering→reverse gluing tenter→calendering→inspection→finished product.

[0026] Among them, the parameters in each step are set as follows:

[0027] During cold pad-batch treatment, use 40g / L caustic soda and 8g / L hydrogen peroxide to pad-roll the gray cloth, and roll and stack it for 12 hours after pad-rolling.

[0028] When scouring, first carry out immersion, and then carry out steaming. Among them, the immersion method is five immersion and five rolling, the liquid carrying rate is 80%, and the tension of the washing machine is set to 4Mpa; the auxiliary agents for immersion include desizing and refining agent YZ-1118, chelating agent, caustic soda, hydrogen peroxide, and water glass. The concentration of desizing and scouring agent is 4g / L, the concentration of ...

Embodiment 2

[0042]The difference between this embodiment and Embodiment 1 is that the composition and proportioning of the waterproof finishing liquid in this embodiment are different, and the specific settings are as follows:

[0043] The mass ratio of the waterproofing agent DM-3680K, waterproofing agent DM-3665, waterproofing agent DM-1000 and waterproofing agent DTM648-2 is 2:2:1:1. The addition amount of magnesium chloride is 5.5g / L.

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that the composition and proportioning of the waterproof finishing liquid in this embodiment are different, and the specific settings are as follows:

[0046] The mass ratio of the waterproofing agent DM-3680K, waterproofing agent DM-3665, waterproofing agent DM-1000 and waterproofing agent DTM648-2 is 1:4:2:2. The addition amount of magnesium chloride is 4.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com