Preparation method of amino modified TiO2 leather fiber

A kind of leather fiber, amino modification technology, applied in the direction of light fast fiber, fiber treatment, textile and paper making, etc., can solve the problem of aging of finishing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides an amino-modified TiO 2 The preparation method of leather fiber, comprises the following steps:

[0016] 1) Use silane coupling agent (3-aminopropyltriethoxysilane) to TiO 2 surface chemical modification to make TiO 2 Amino groups on the surface: add 3-5g TiO 2 Add a silane coupling agent with a volume fraction of 0.5-1%, mix and stir for 2-3 hours, and control the temperature at 60-80° C. After the reaction is completed, filter and dry at 110° C. for 10-20 minutes.

[0017] 2) Utilize sodium chloroacetate to carry out carboxylation to leather fiber, make leather fiber have more reactive groups:

[0018] 2.1) Add 20-30 g of chloroacetic acid and 15-20 mL of water into a three-necked flask, stir to dissolve, and at the same time add 30-50% sodium hydroxide solution dropwise to neutralize to obtain sodium chloroacetate;

[0019] 2.2) Soak 3-5g of leather in 100-200mL of deionized water, soak for 10-12h, then put it in a water bath constant tempe...

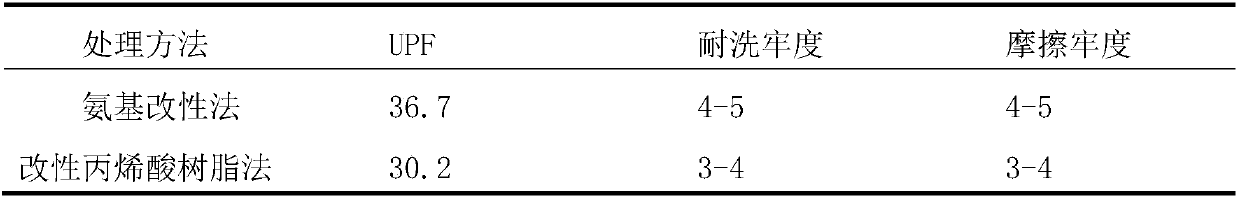

Embodiment 1

[0027] (1) 3g TiO 2 Add a silane coupling agent with a volume fraction of 0.5%, mix and stir for 3 hours, and control the temperature at 60°C. After the reaction is completed, filter and dry at 110°C for 15 minutes.

[0028] (2) Add 20 g of chloroacetic acid and 15 mL of water into a three-necked flask, stir to dissolve, and simultaneously add 30% sodium hydroxide solution dropwise for neutralization to obtain sodium chloroacetate. Then soak 3g of leather in 100mL of deionized water, soak for 10h, then put it in a water bath constant temperature oscillator and shake for 4h. Sodium chloroacetate is added to the remoistened leather for reaction at a temperature of 45°C, with NaHCO 3 The pH value of the adjustment system was maintained at 7.5, and the reaction was carried out for 6 hours.

[0029] (3) Put the product prepared in the above (1) and above (2) into a 100mL beaker, add 0.05g / mL zirconium sulfate solution, the pH of the system is 1.5, and stir for 3h. After the reac...

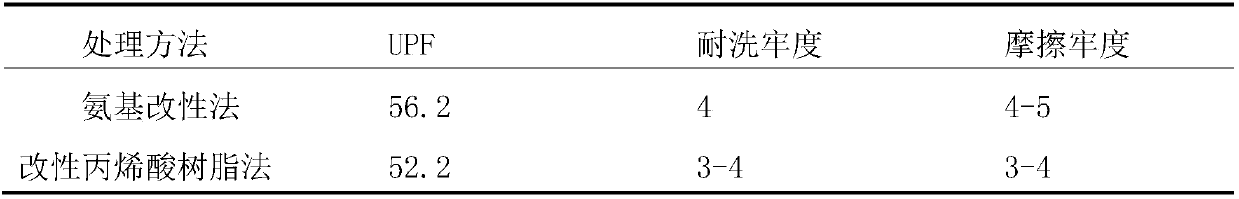

Embodiment 2

[0036] (1) 5g TiO 2 Add a silane coupling agent with a volume fraction of 1%, mix and stir for 3 hours, and control the temperature at 60° C. After the reaction is completed, filter and dry at 110° C. for 15 minutes.

[0037] (2) Add 22 g of chloroacetic acid and 15 mL of water into a three-necked flask, stir to dissolve, and simultaneously add 30% sodium hydroxide solution dropwise for neutralization to obtain sodium chloroacetate. Then soak 3g of leather in 100mL of deionized water, soak for 10h, then put it in a water bath constant temperature oscillator and shake for 4h. Sodium chloroacetate is added to the remoistened leather for reaction at a temperature of 45°C, with NaHCO 3 Adjust the pH value of the system to keep it at 8, and react for 6 hours.

[0038] (3) Put the product prepared in the above (1) and above (2) into a 100mL beaker, add 0.07g / mL zirconium sulfate solution, the pH of the system is 1.5, and stir for 4h. After the reaction, filter, wash with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com