Numerical simulation method for selective laser repair process

A technology of laser repair and numerical simulation, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high laser power, uneven stress distribution, fast cooling rate, etc., and achieve low analysis cost and accuracy High, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

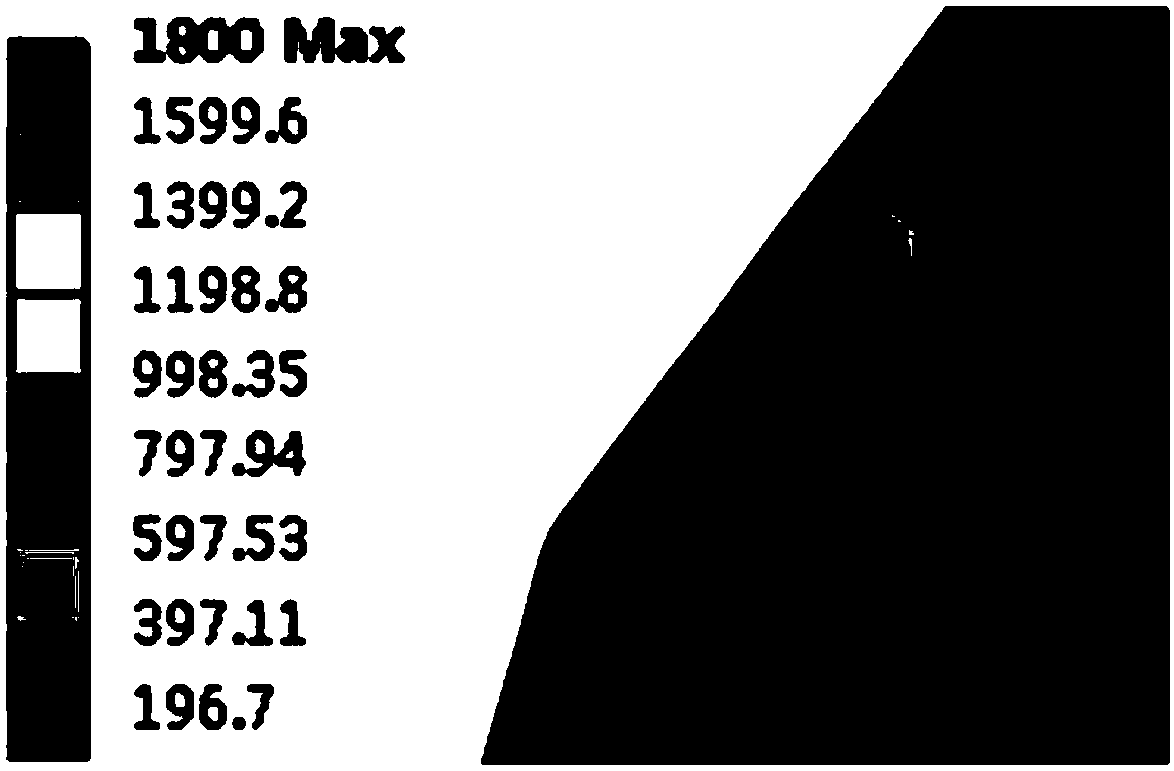

[0051]Step 1: Establish a 3D model of the repaired part of the first-class turbine blade and the groove of the repaired zone in 3D software; carry out mesh division of different mesh types and different sizes of cells for the entire area of the repaired model; laser repair and close-up The repair area (repair heat-affected zone) is divided into fine grids and analyzed with full hexahedron elements (the smallest mesh unit is 0.1mm), which not only improves the calculation accuracy compared with tetrahedron, but also reflects the regularity of additive manufacturing; the repair area In the rest of the transition area with the original model, the mesh size increases with the distance from the repaired area, and the hybrid mesh of tetrahedron and hexahedron is used for division (that is, the division is based on the hexahedron overall module algorithm, and the grid gap is added. Tetrahedral grid, the triangular vertices of the tetrahedral grid are docked with the nearest hexahedr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com