Composite electrode material, preparation method thereof and application of material

A composite electrode, mixed solution technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., to achieve the effect of improving electrical conductivity and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

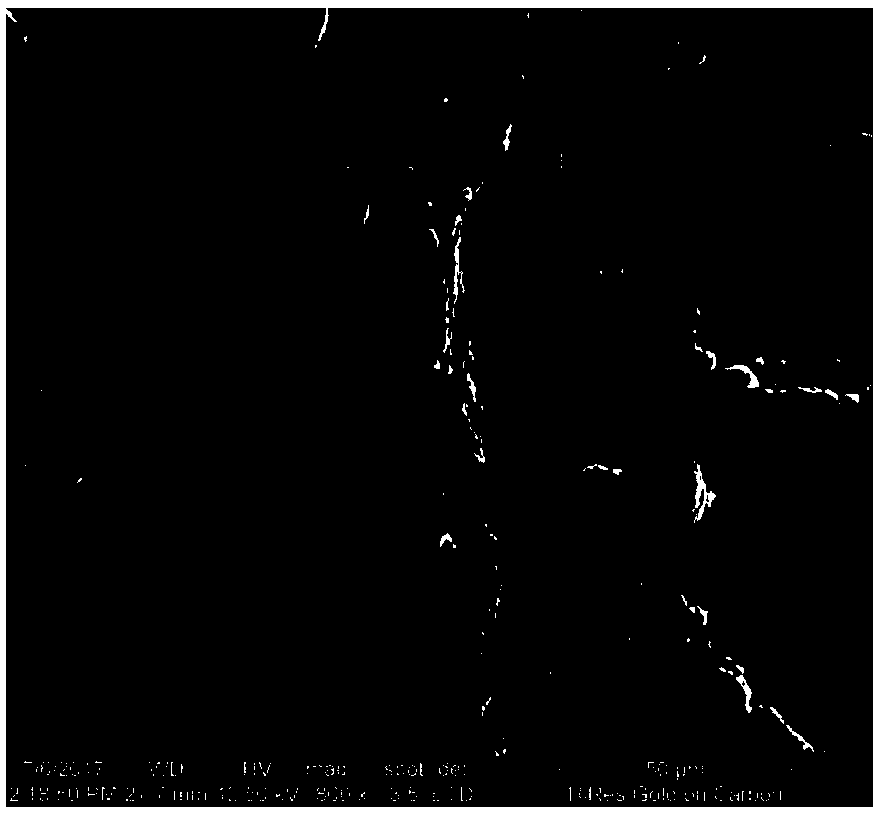

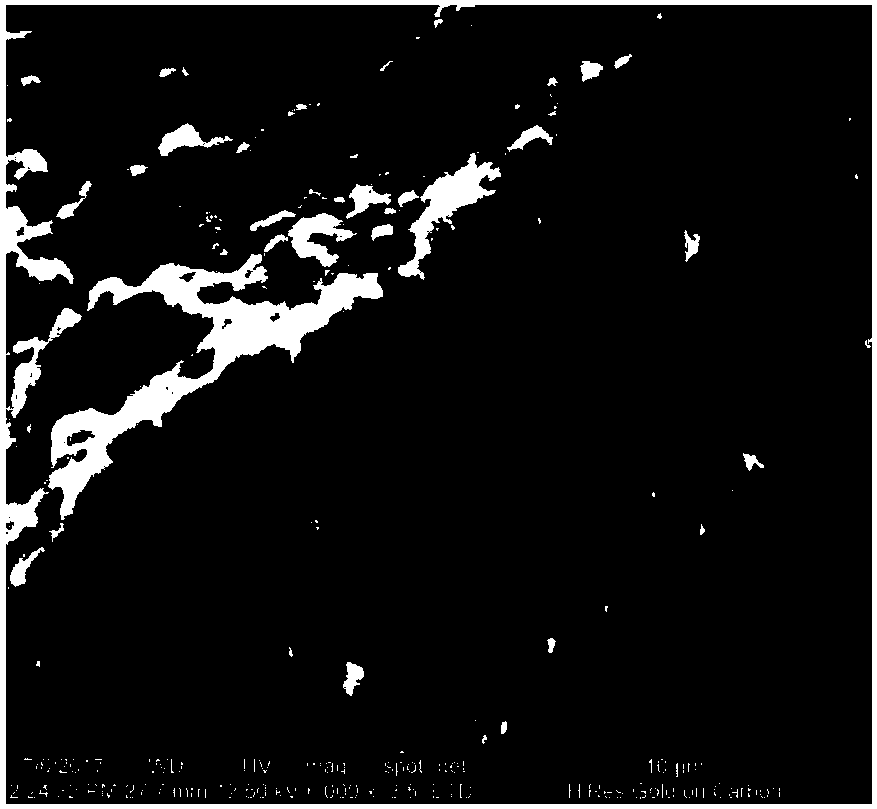

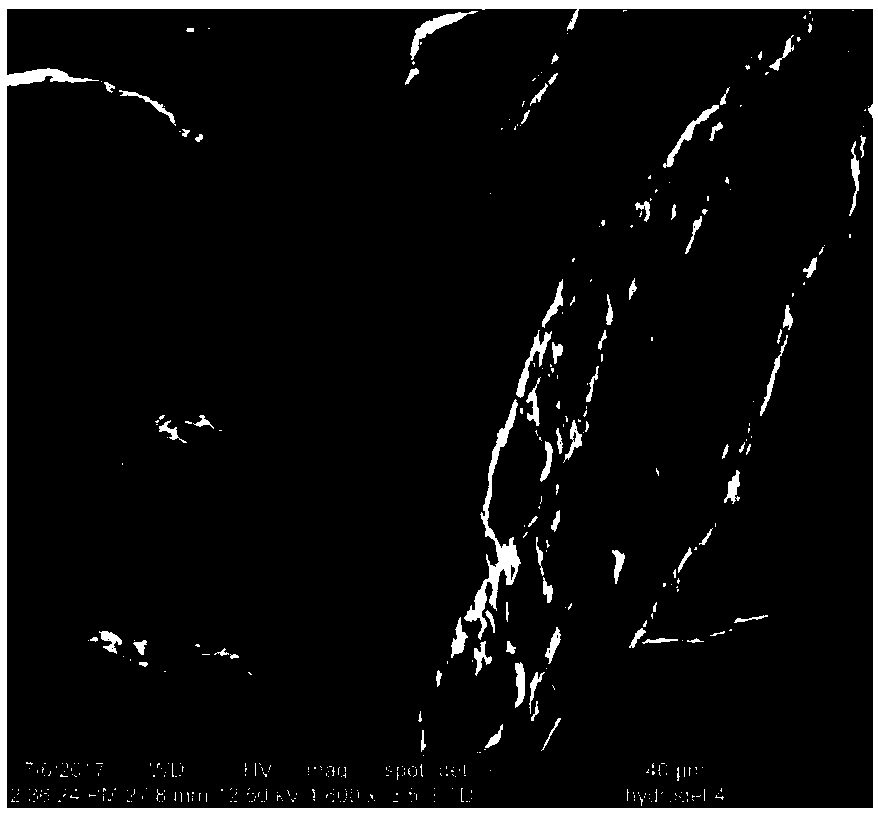

[0063] Mix nano-silica powder (particle size: 50-100nm), carbon nanotubes, and polyvinylpyrrolidone in 100ml of water at a mass ratio of 100mg:100mg:100mg, then ultrasonically disperse for 30min with an ultrasonic breaker, and add 2g of sodium alginate to continue the mechanical process. After stirring for 2 hours, add 1.5 g of copper hydroxide and mechanically stir for 30 minutes, then add 3 g of gluconolactone, stir evenly, let stand for 24 hours, and then freeze-dry for 24 hours. The freeze-dried product was heated to 400° C. for carbonization in a tube furnace for 2 h, and nitrogen was used as a protective gas in the tube furnace. After the furnace was cooled down to room temperature, the silicon-carbon composite electrode material was obtained. figure 1 , figure 2 From the SEM image of its material, it can be seen from the figure that the freeze-dried material presents a three-dimensional grid shape, and the average layer thickness is 8-10 μm. image 3 It is the SEM pi...

Embodiment 2

[0065] Mix nano-silica powder (particle size 50-100nm), carbon nanotubes, and polyvinylpyrrolidone in 100ml of water according to the mass ratio of 200mg:100mg:100mg, then use an ultrasonic breaker to ultrasonically disperse for 30min, then add 2g of sodium alginate to continue After mechanical stirring for 2 hours, add 1.5g of copper hydroxide and mechanically stir for 30 minutes, then add 3g of gluconolactone, stir evenly, let stand for 24 hours, and then freeze-dry for 24 hours. The freeze-dried product was heated to 400° C. for carbonization in a tube furnace for 2 h, and nitrogen was used as a protective gas in the tube furnace. After the furnace was cooled down to room temperature, the silicon-carbon composite electrode material was obtained. Figure 6 --8 In order to obtain the SEM characterization results of the material, compared with Example 1, with the increase in the quality of nano-silicon powder, the three-dimensional grid-like structure does not change, and copp...

Embodiment 3

[0067] Mix nano-silica powder (particle size: 50-100nm), carbon nanotubes, and polyvinylpyrrolidone in 100ml of water according to the mass ratio of 100mg:200mg:200mg, then use an ultrasonic breaker to ultrasonically disperse for 30min, then add 2g of sodium alginate to continue After mechanical stirring for 2 hours, add 1.5g of copper hydroxide and mechanically stir for 30 minutes, then add 3g of gluconolactone, stir evenly, let stand for 24 hours, and then freeze-dry for 24 hours. The freeze-dried product was heated to 400° C. for carbonization in a tube furnace for 2 h, and nitrogen was used as a protective gas in the tube furnace. After the furnace was cooled down to room temperature, the silicon-carbon composite electrode material was obtained. Figure 9 --11 is the SEM characterization result of the obtained material. As the mass of carbon nanotubes increases, the three-dimensional grid-like structure of the composite electrode material becomes a honeycomb structure. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com