Preparation method of different valence cobalt-carbon nanometer composite materials

A nanocomposite material and composite material technology, applied in different valence cobalt-carbon series nanocomposite materials and its preparation field, can solve the problems of increased energy consumption, high reserves, limited water splitting efficiency, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

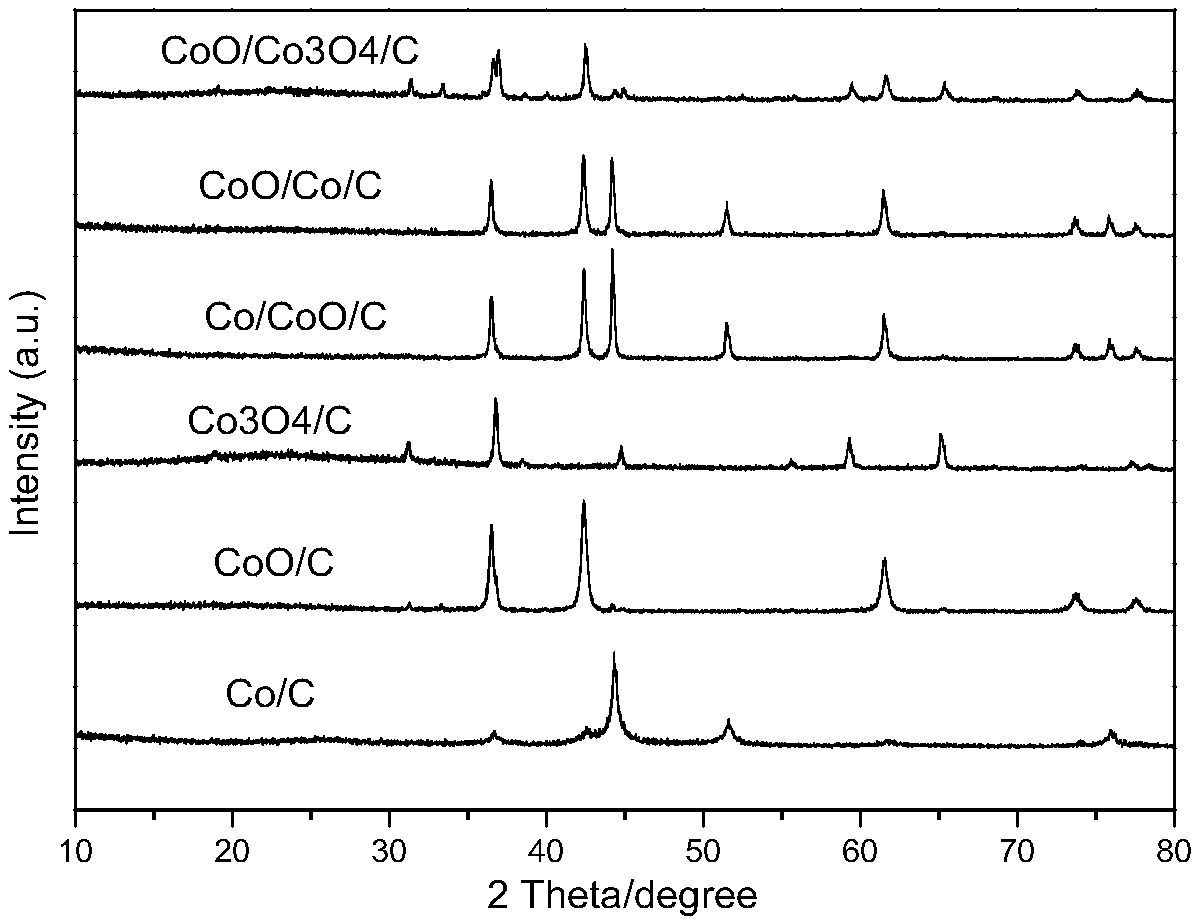

Embodiment 1

[0018] Mix cobalt salts and imidazole ligands in a molar ratio of 1:3.667 in a mixed solvent of methanol and ethanol (v:v=1:1), stir the mixed solution for 30 minutes, and let stand at room temperature for 24 hours. The resulting product is washed, Filter and dry at 80°C for later use. The cobalt-carbon nanocomposite material can be obtained by pyrolyzing the prepared zeolite imidazole metal organic framework material as a precursor at a high temperature of 600 degrees for 3 hours in an inert atmosphere.

Embodiment 2

[0020] Mix cobalt salts and imidazole ligands in a molar ratio of 1:3.667 in a mixed solvent of methanol and ethanol (v:v=1:1), stir the mixed solution for 30 minutes, and let stand at room temperature for 24 hours. The resulting product is washed, Filter and dry at 80°C for later use. The prepared zeolite imidazole-based metal-organic framework material is used as a precursor and decomposed by hydrothermal heat at 140 degrees for 9 hours to obtain tricobalt tetroxide-carbon nanocomposite material.

Embodiment 3

[0022] Mix cobalt salts and imidazole ligands in a molar ratio of 1:3.667 in a mixed solvent of methanol and ethanol (v:v=1:1), stir the mixed solution for 30 minutes, and let stand at room temperature for 24 hours. The resulting product is washed, Filter and dry at 80°C for later use. Weigh 50 mg of zeolite imidazole metal organic framework material as a precursor and disperse it in 50 ml of ethanol aqueous solution, add 3 mL of 1M sodium borohydride aqueous solution to the ice-water bath, stir for 5 minutes, and then place it in a hydrothermal reaction kettle for 7 hours at 150 degrees to react. A cobaltous hydroxide-carbon nanocomposite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com