Preparation method of enhanced viscosity reduction type polycarboxylic acid plasticizer

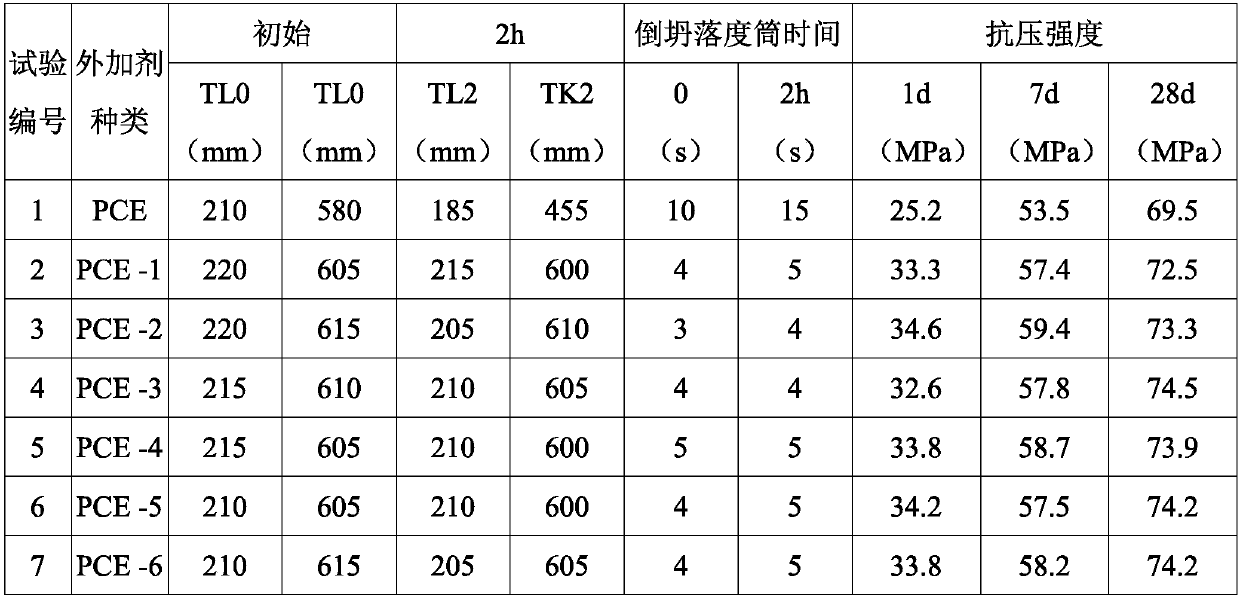

A plasticizer and polycarboxylic acid technology, applied in the field of construction admixtures, can solve the problems of high viscosity of freshly mixed concrete, frequent pumping accidents, difficult pumping, etc., achieve high water reduction rate, improve early strength and The effects of late strength and excellent slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Acylation reaction: Mix 514.00g of maleic anhydride, 100.00g of monoethanolamine, 5.00g of hydroquinone and 6.00g of periodic acid. Under the protection of nitrogen, heat up to 65°C and keep it warm for 4 hours. Or the method of logical nitrogen band water is removed water, after reaction finishes, be down to room temperature, obtain the first mixture that contains acylated product and unreacted maleic anhydride;

[0028] (2) Esterification reaction: 198.00g hydroxyethyl acrylate, 100.00g 2-amino-4-methyl-5-phospho-3-pentenoic acid ethyl ester, 5.20g hydroquinone and 4.20g dinitrobenzene Mix formic acid, under the protection of nitrogen, raise the temperature to 60°C and keep it warm for 3 hours. During this period, remove the water by vacuuming or nitrogen with water. the second mixture of

[0029] (3) Monomer blending: 18.00g of the first mixture prepared in step (1), 5.00g of the second mixture prepared in step (2), 4.00g of 3-trimethylsiloxy-2-butenoic acid Me...

Embodiment 2

[0033] (1) Acylation reaction: Mix 434.00g of acrylic acid, 100.00g of diethanolamine, 4.50g of phenothiazine and 5.30g of dinitrobenzoic acid. Under the protection of nitrogen, heat up to 60°C and keep it warm for 4 hours. During this period, use vacuum or Water is removed by nitrogen gas with water, and the reaction is cooled to room temperature after completion of the reaction to obtain the first mixture containing acylated product and unreacted acrylic acid;

[0034] (2) Esterification reaction: 249.00g hydroxypropyl acrylate, 100.00g 2-amino-4-methyl-5-phospho-3-pentenoic acid, 4.00g hydroquinone and 4.00g periodic acid were mixed, Under the protection of nitrogen, raise the temperature to 65°C and keep it warm for 2 hours. During this period, remove the water by vacuuming or blowing nitrogen with water. After the reaction, cool down to room temperature to obtain the second mixture containing the esterification product and unreacted hydroxypropyl acrylate. ;

[0035] (3)...

Embodiment 3

[0039] (1) Acylation reaction: Mix 290.00g of methacrylic acid, 100.00g of triethanolamine, 2.30g of diphenylamine and 3.00g of periodic acid. Under the protection of nitrogen, heat up to 70°C for 3 hours. The method of nitrogen band water is removed water, and after reaction finishes, be down to room temperature, obtain the first mixture that contains acylated product and unreacted methacrylic acid;

[0040] (2) Esterification reaction: 210.00g hydroxyethyl methacrylate, 100.00g 2-amino-4-methyl-5-phospho-3-pentenoic acid ethyl ester, 4.00g phenothiazine and 1.80g ethylenediamine Mix tetraacetic acid, under the protection of nitrogen, raise the temperature to 70°C and keep it warm for 2 hours. During this period, use vacuum or nitrogen with water to remove water. After the reaction, cool down to room temperature to obtain esterification products and unreacted methacrylic acid. A second mixture of hydroxyethyl esters;

[0041] (3) Monomer blending: 22.00g of the first mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com