A kind of superfine fiber synthetic leather resin for automobile interior decoration and preparation method thereof

A technology for ultra-fine fibers and automotive interiors, which is applied in the field of ultra-fine fiber synthetic leather resins for automotive interiors and its preparation, and can solve the problems of high cost, low utilization rate, and heavy metal content that easily exceed the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

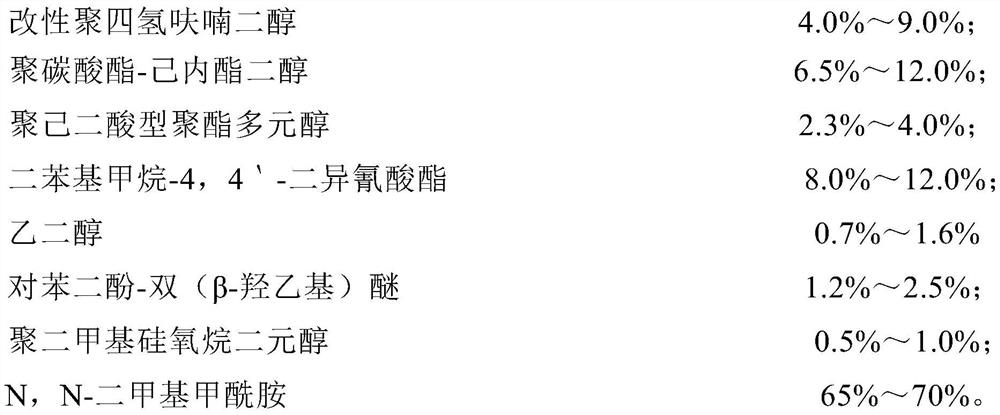

[0025] 1. Formula

[0026]

[0027] 2. Preparation method

[0028] Put polycarbonate-caprolactone diol (number-average molecular weight 2000g / mol) 76kg, polyadipate type polyester polyol (number-average molecular weight 2000g / mol) 38kg, polyadipate-3 formaldehyde in the reactor Base-1,5-pentanediol ester diol (number-average molecular weight 2000g / mol) 11kg, N,N-dimethylformamide 94kg, after stirring evenly, put in diphenylmethane-4,4'-diisocyanate 15.6kg , the reaction temperature is controlled at 75-85°C. After reacting for 4-6 hours, when the viscosity of the reaction system reaches 80-90Pa·s / 50°C, put 76kg of modified polytetrahydrofuran diol (number-average molecular weight 2000g / mol) into the reaction kettle , 13.9kg of ethylene glycol, 14.8kg of hydroquinone-bis(β-hydroxyethyl) ether and 308kg of N,N-dimethylformamide, stir well and put in diphenylmethane-4,4'-diphenylmethane 79.3 kg of isocyanate, the reaction temperature is controlled at 75-85°C, after 1-2 hours ...

Embodiment 2

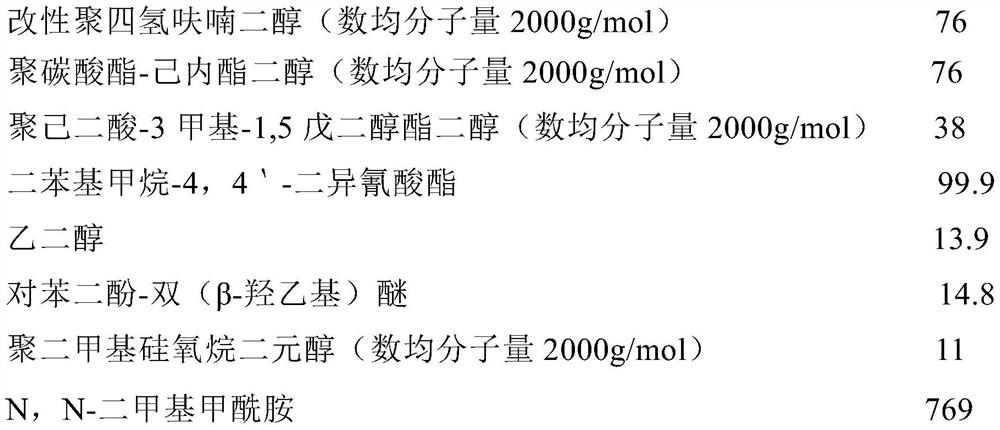

[0030] 1. Formula

[0031]

[0032] 2. Preparation method

[0033] Put polycarbonate-caprolactone diol (number average molecular weight 2000g / mol) 120kg, polyadipate type polyester polyol (number average molecular weight 3000g / mol) 40kg, polydimethylsiloxane in the reactor 10kg of dihydric alcohol (number average molecular weight 2000g / mol), 102kg of N,N-dimethylformamide, after stirring evenly, put in 19kg of diphenylmethane-4,4'-diisocyanate, and control the reaction temperature at 75-85°C , after reacting for 4-6 hours, when the viscosity of the reaction system reaches 90-110Pa·s / 50°C, put 40kg of modified polytetrahydrofuran diol (number-average molecular weight 3000g / mol) and 7.1kg of ethylene glycol into the reaction kettle. Diphenol-bis(β-hydroxyethyl) ether 22.6kg and N, N-dimethylformamide 290kg, after stirring evenly, drop into diphenylmethane-4, 4'-diisocyanate 58kg, the reaction temperature is controlled at 75~ 85°C, after reacting for 1-2 hours, add the remai...

Embodiment 3

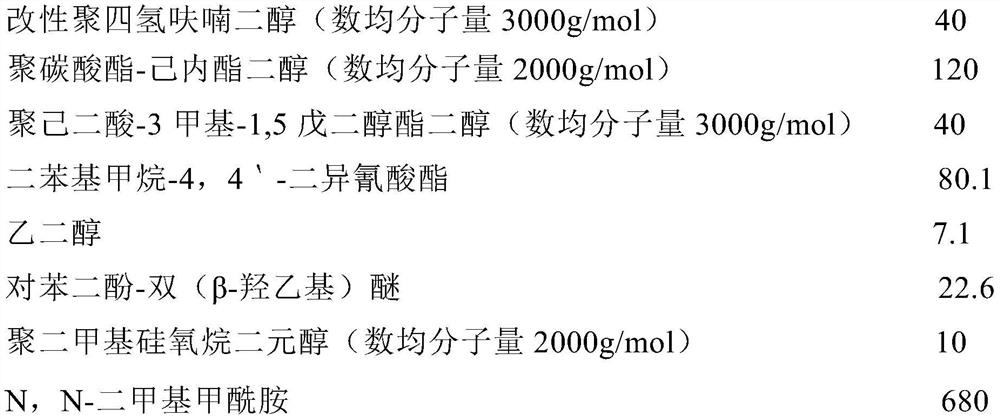

[0035] 1. Formula

[0036]

[0037] 2. Preparation method

[0038]In the reactor, drop into polycarbonate-caprolactone diol (number average molecular weight 2000g / mol) 66kg, polyadipate-3 methyl-1,5 pentanediol ester diol (number average molecular weight 3000g / mol) 28kg, polydimethylsiloxane diol (number-average molecular weight 2000g / mol) 8kg, N, N-dimethylformamide 114kg, after stirring evenly, drop into diphenylmethane-4, 4'-diisocyanate 11.5 kg, the reaction temperature is controlled at 75-85°C, and after 4-6 hours of reaction, when the viscosity of the reaction system reaches 100-110Pa·s / 50°C, put modified polytetrahydrofuran diol (number-average molecular weight 2000g / mol) into the reaction kettle 94kg, 16.4kg of ethylene glycol, 26.2kg of hydroquinone-bis(β-hydroxyethyl) ether and 305kg of N,N-dimethylformamide, stir well and put into diphenylmethane-4,4'- 106 kg of diisocyanate, the reaction temperature is controlled at 75-85°C, after 1-2 hours of reaction, add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com