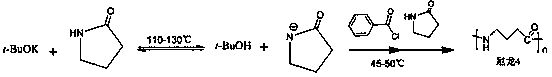

Synthetic process of poly-alpha-pyrrolidone based on anion open loop polymerization

A polybutyrolactam and anion ring-opening technology, applied in the field of nylon synthesis technology, can solve the problems of low reaction speed, complicated procedures, difficult to use on a large scale, and achieve the effects of simplifying production technology and equipment and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of anionic ring-opening polymerization method synthesizes polybutyrolactam, and its steps are as follows:

[0034] Step 1. Reaction container handling

[0035] Add 200g of butyrolactam into a four-necked flask, said four-necked flask: the specification is 500ml, and it has been deoxygenated and dried; the four-necked flask is respectively connected with nitrogen, mechanical stirring paddle, temperature sensor and vent;

[0036] The deoxygenation and drying: the four-neck flask is dried in an oven, and the flask is ventilated with nitrogen at room temperature for 15 minutes to ensure that the air is removed, and the nitrogen flux is kept at 500ml / min.

[0037] Step 2, Nitrogen

[0038] The four-neck flask was heated to 110°C under nitrogen, and the nitrogen flux was kept at 500 ml / min.

[0039] Step 3. Activation

[0040] Add 13.33g of potassium tert-butoxide solid into the four-neck flask, stir to dissolve, set the rotation speed at 200r / min, activate for 3h, ...

Embodiment 2

[0049] A kind of anionic ring-opening polymerization method synthesizes polybutyrolactam, and step is as follows:

[0050] Step 1. Reaction container handling

[0051] Add 200g of butyrolactam into a four-necked flask, said four-necked flask: the specification is 500ml, and it has been deoxygenated and dried; the four-necked flask is respectively connected with nitrogen, mechanical stirring paddle, temperature sensor and vent;

[0052] The deoxygenation and drying: the four-neck flask is dried in an oven, and the flask is ventilated with nitrogen at room temperature for 15 minutes to ensure that the air is removed, and the nitrogen flux is kept at 500ml / min.

[0053] Step 2, Nitrogen

[0054] The four-neck flask was heated to 120 °C under nitrogen, and the nitrogen flux was kept at 500 ml / min.

[0055] Step 3. Activation

[0056] Add 9.5-10 g of potassium tert-butoxide solid into the four-neck flask, stir to dissolve, set the rotation speed at 300 r / min, activate for 6 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com