Graphene/Ag-carbon microsphere aerogel coating and preparation method and application thereof

A technology of carbon microspheres and aerogels, which is applied in the direction of airgel preparation, chemical instruments and methods, coatings, etc., can solve the problems of poor anti-smog effect, achieve adsorption performance, improve anti-smog performance, Good anti-smog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Specifically, a kind of graphene / Ag-carbon microsphere airgel coating of the present invention is prepared by the following steps:

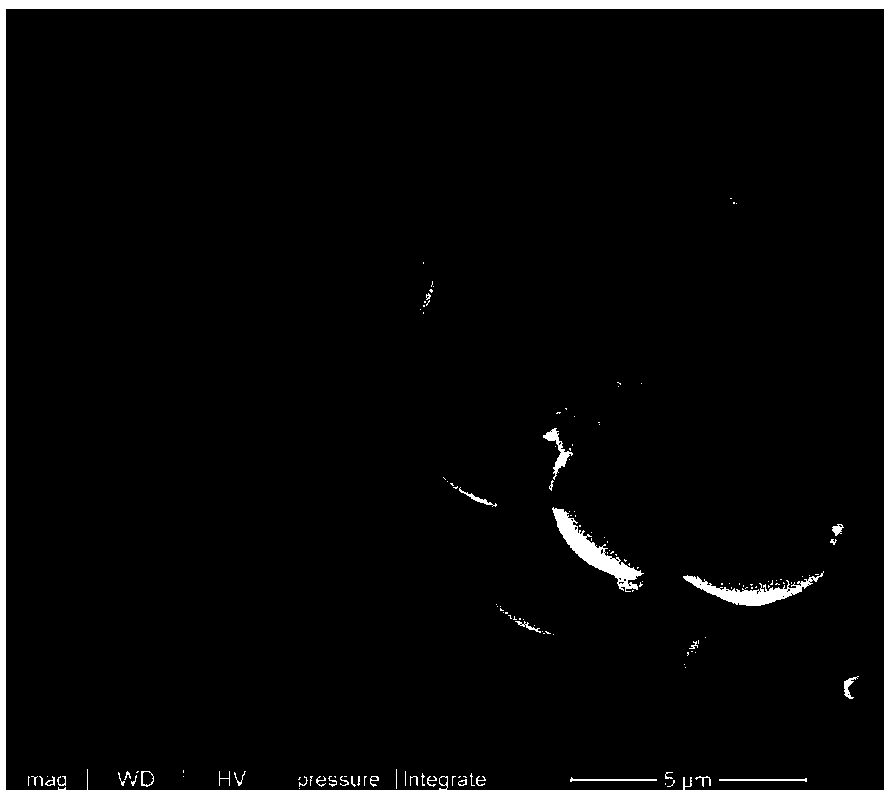

[0046] Step 1, preparation of nano Ag-carbon microspheres

[0047] Adding AgNO to the suspension of carbon microspheres with a mass concentration of 0.3-0.5% wt 3 solution to obtain a mixed solution, and the Ag in the mixed solution + The concentration is 1~1.5mol / L, the obtained carbon microspheres-AgNO 3 The mixed solution was stirred with a 180-220rpm magnetic rotor for 20-24h, then centrifuged at a speed of 2800-3000rpm for 10-15min to remove excess silver ions, and then the obtained nano-Ag-carbon microspheres were washed with distilled water and alcohol, and then washed again with After ultrasonic dispersion for 45-60 minutes, uniform nanometer Ag-carbon microspheres can be obtained. The carbon microspheres have a hollow structure with a specific surface area of 1800-2200 g / m 2 , the size of the nano-silver ions in the obtained...

Embodiment 1

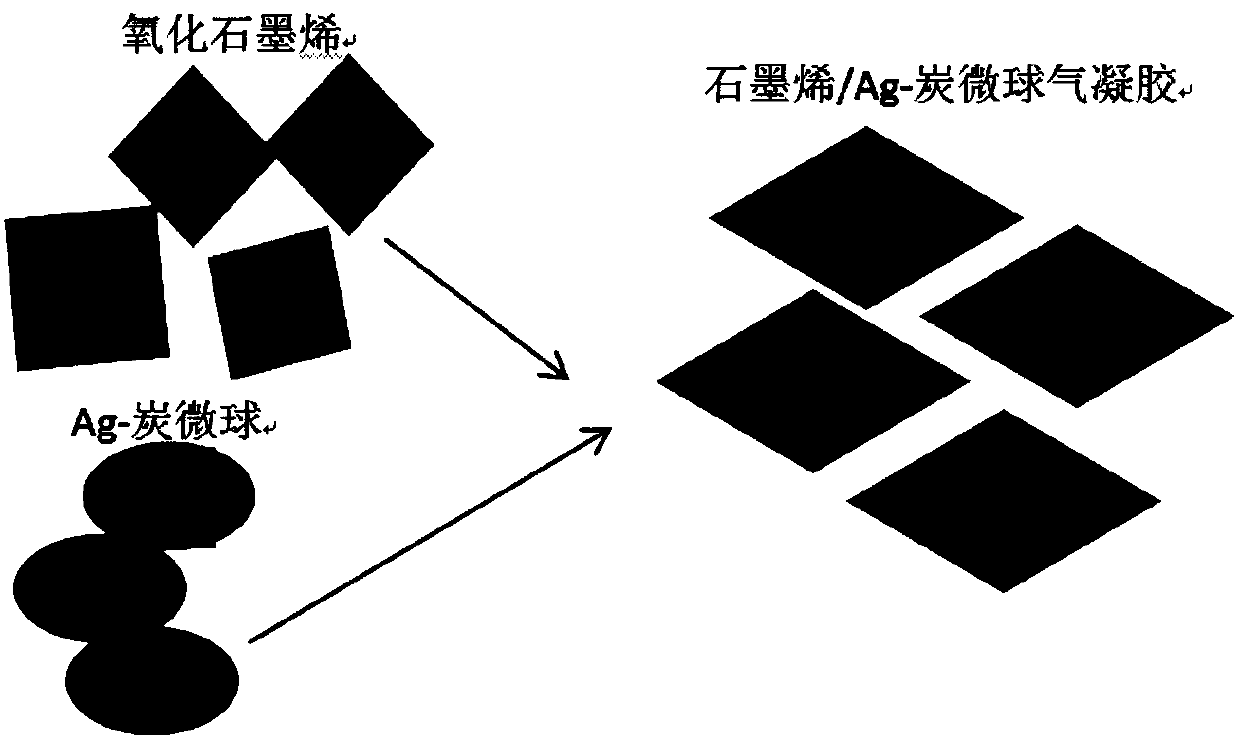

[0060] A kind of preparation method of graphene / Ag-carbon microsphere airgel coating of the present embodiment, its preparation process schematic diagram and flow chart are as follows image 3 , Figure 4 As shown, it specifically includes the following steps:

[0061] (1) Preparation of carbon microspheres: using cellulose as a raw material, carbon microspheres were prepared by hydrothermal carbonization.

[0062] Specifically, weigh 0.8g of cellulose into a 20ml sample bottle, add 15mL of deionized water, stir magnetically for 30min at a speed of 30r / min, and disperse the cellulose evenly in the solution, then place it in a 25mL Inside the hydrothermal reactor. After sealing the hydrothermal reaction kettle, put it into a muffle furnace and keep it constant for 7 hours at 220°C, and then naturally cool it to room temperature in the muffle furnace. The substance in the lower layer of the hydrothermal reaction kettle was suction-filtered, washed with absolute ethanol and di...

Embodiment 2

[0070] A kind of preparation method of graphene / Ag-carbon microsphere airgel coating of the present embodiment, its preparation process schematic diagram and flow chart are as follows image 3 , Figure 4 As shown, it specifically includes the following steps:

[0071] (1) Preparation of carbon microspheres: using cellulose as a raw material, carbon microspheres were prepared by hydrothermal carbonization.

[0072] Specifically, weigh 0.8g of cellulose into a 20ml sample bottle, add 10mL of deionized water, stir magnetically at a speed of 40r / min for 20min, and disperse the cellulose evenly in the solution, then place it in a 25mL Inside the hydrothermal reactor. After sealing the hydrothermal reaction kettle, put it into a muffle furnace and keep it constant for 8 hours at 200°C, and then naturally cool it to room temperature in the muffle furnace. The substance in the lower layer of the hydrothermal reaction kettle was suction-filtered, washed with absolute ethanol and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com