A water-based UV-curable bmc high temperature resistant coating

A high-temperature-resistant coating and ultraviolet light technology, which is applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unusable coatings, environmental pollution, and coatings that are not resistant to high temperatures, so as to improve the brightness of light, The effect of ensuring driving safety and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of this coating is:

[0022] (1) Add 10-15 parts of acrylic acid monomer and 5-10 parts of co-solvent into the reactor, start stirring for 10 minutes, frequency: 600-800r / min, temperature: 30-45°C;

[0023] (2) Adjust the stirring frequency to 200-300r / min, add 20-30 parts of water-based polyurethane acrylic resin and 25-30 parts of water-based acrylated acrylic resin into the reactor, adjust the stirring frequency to 1000-1200r / min, Stir for 20 minutes;

[0024] (3) Adjust the stirring frequency to 200-300r / min, add 3-5 parts of photoinitiator and 0.2-0.4 parts of leveling agent into the reactor, adjust the stirring frequency to 600-800r / min, and stir for 10 minutes;

[0025] (4) Adjust the stirring frequency to 200-300r / min, add 30-40 parts of photoinitiator into the reactor, adjust the stirring frequency to 600-800r / min, stir for 30 minutes, then stop stirring, and discharge for inspection.

Embodiment 1

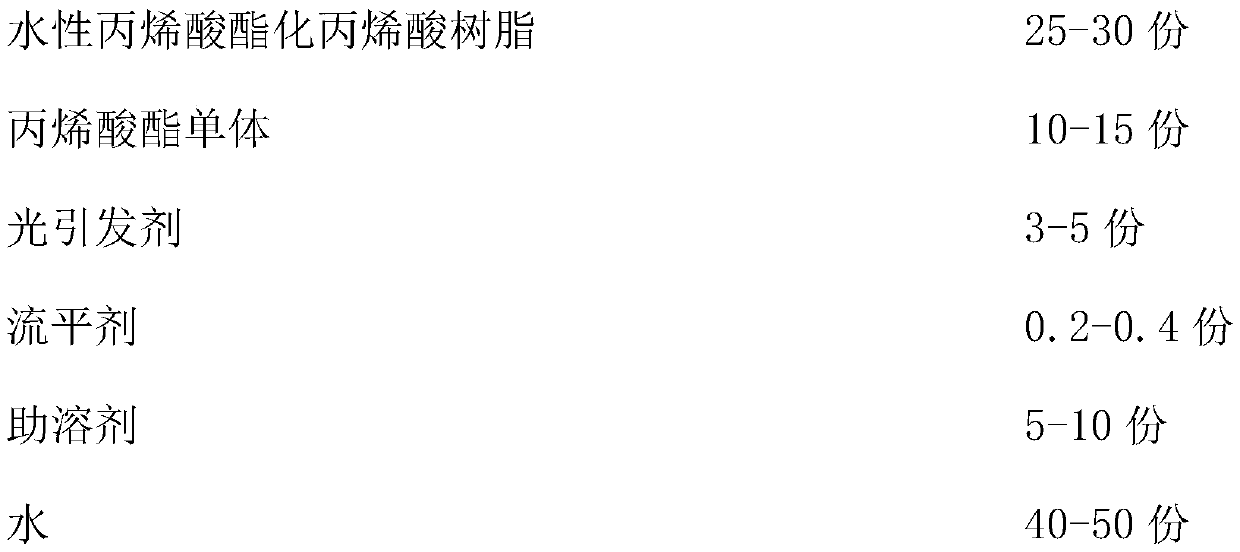

[0027] A water-based UV-curable BMC high-temperature-resistant coating, comprising the following components in parts by weight:

[0028] raw material Ratio / by weight Numbering Waterborne polyurethane acrylic resin 25 B-717 (6 functional resin) Water-based acrylated acrylic resin 30 LUX515 Acrylate monomer 10 Propoxylated Trimethylolpropane Triacrylate Photoinitiator 4 2-Hydroxy-2-methyl-1-phenyl-1-propanone leveling agent 0.3 BYK333 Co-solvent 5 Ethylene glycol butyl ether water 40

Embodiment 2

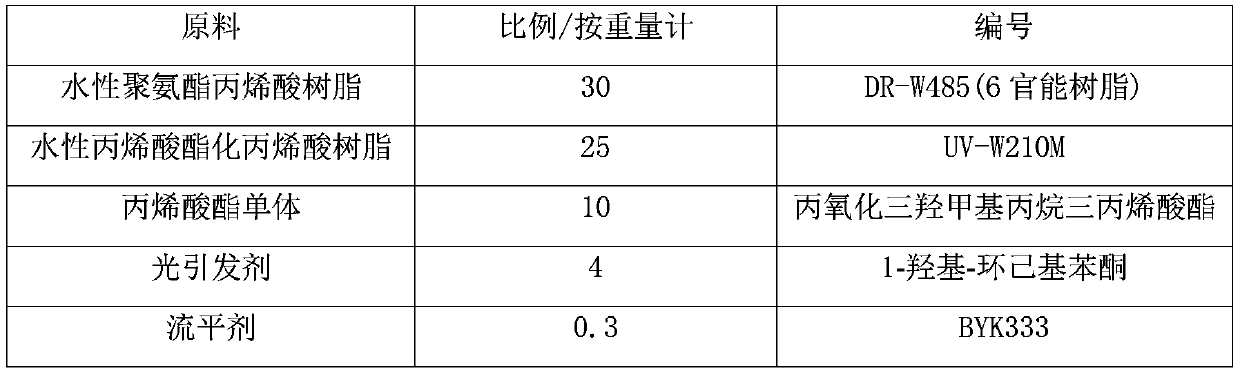

[0030] A water-based UV-curable BMC high-temperature-resistant coating, comprising the following components in parts by weight:

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com