Art type epoxy resin zinc-rich anti-corrosion powder coating

A technology of epoxy resin and powder coating, applied in the field of powder coating, to achieve the effect of good corrosion resistance and salt spray resistance, and good resistance to medium penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

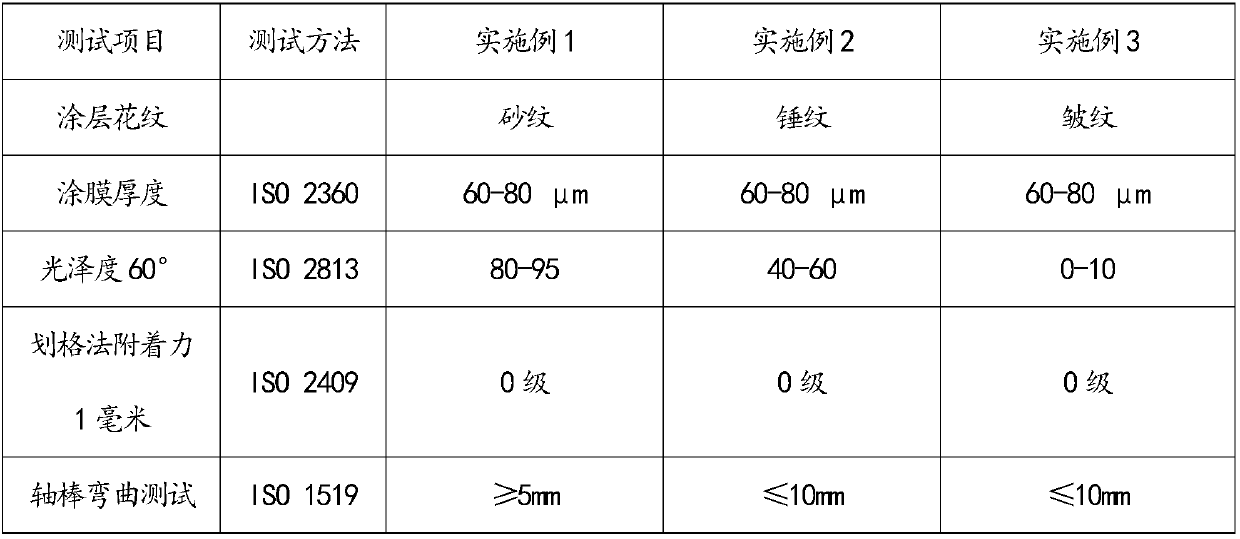

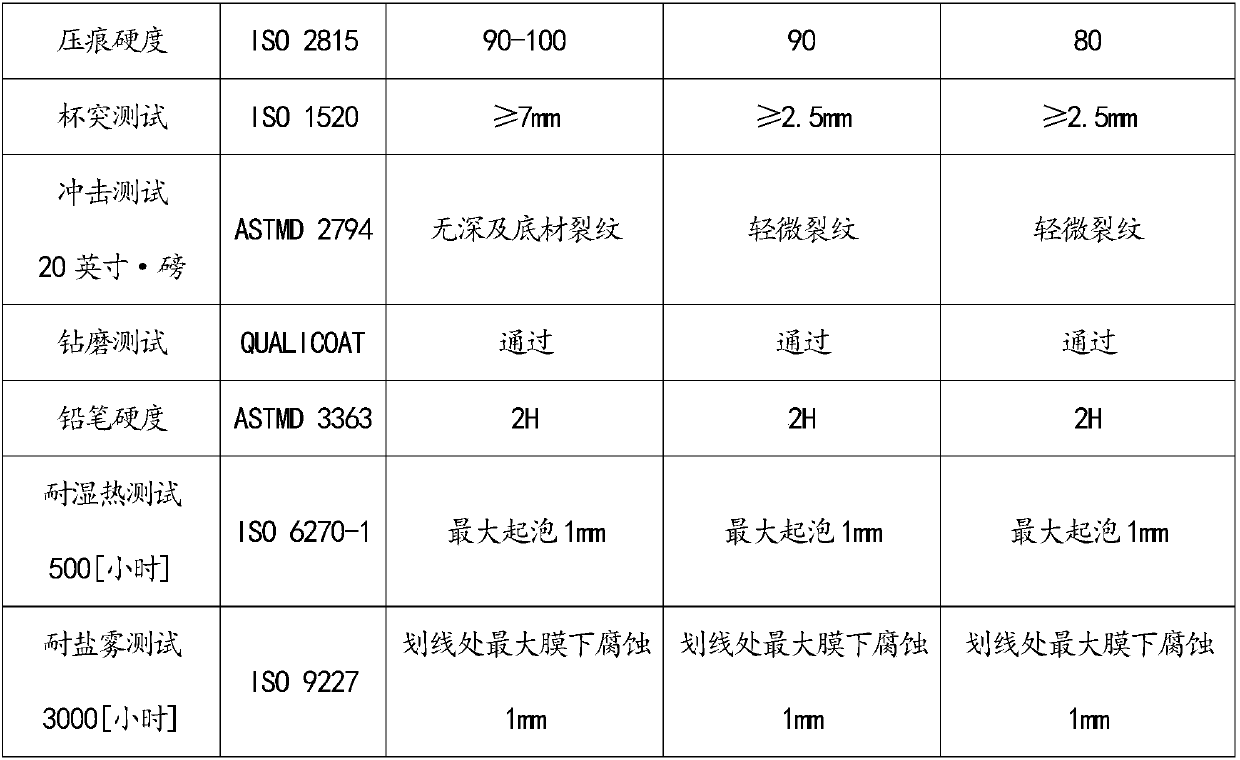

Examples

Embodiment 1

[0039] An art-type epoxy resin zinc-rich anticorrosive powder coating formulation, which includes the following raw materials in parts by weight: 60 parts of epoxy resin, 5 parts of curing agent, 25 parts of titanium dioxide, 30 parts of barium sulfate, and acrylic leveling agent 1 part, 1 part of acrylic wetting agent, 1 part of benzoin, 1 part of stearic acid, 5 parts of matting agent, 1 part of polyethylene wax, 1 part of polyamide wax, 1 part of antifoaming agent, polytetrafluoroethylene wax 1 part, 1 part of charge regulator, 1 part of organic bentonite, 2 parts of catalyst, 40 parts of zinc powder.

[0040] The epoxy resin is E-12 and novolac epoxy resin with a weight ratio of 1:4.

[0041] The curing agent is an addition product of phenols and epoxy compounds.

[0042] The catalyst is an imidazole derivative.

[0043] The defoamer is a mixture of 50 parts by weight of amide wax, 5 parts by weight of stearic acid, 10 parts by weight of benzoin, and 10 parts by weight of PE wax....

Embodiment 2

[0046] An art-type epoxy resin zinc-rich anticorrosive powder coating formulation, which includes the following raw materials in parts by weight: 60 parts epoxy resin, 5 parts curing agent, 25 parts titanium dioxide, 30 parts barium sulfate, acrylic leveling agent 0.8 parts, acrylic wetting agent 0.8 parts, benzoin 0.8 parts, stearic acid 0.8 parts, matting agent 5 parts, polyethylene wax 1 part, polyamide wax 1 part, antifoaming agent 1 part, polytetrafluoroethylene wax 1 part, 1 part charge regulator, 1 part organic bentonite, 2 parts catalyst, 40 parts zinc powder, 5 parts aluminum silver powder, 4 parts cellulose acetate-butyrate, 4 parts floating flower agent.

[0047] The epoxy resin is E-12 and novolac epoxy resin with a weight ratio of 2:1.

[0048] The curing agent is a novolac resin.

[0049] The catalyst is an imidazole derivative.

[0050] The defoamer is a mixture of 60 parts by weight of amide wax, 8 parts by weight of stearic acid, 15 parts by weight of benzoin, and 15...

Embodiment 3

[0053] An art-type epoxy resin zinc-rich anticorrosive powder coating formulation, which includes the following raw materials in parts by weight: 60 parts epoxy resin, 5 parts curing agent, 25 parts titanium dioxide, 30 parts barium sulfate, acrylic leveling agent 0.5 parts, acrylic wetting agent 0.5 parts, benzoin 0.5 parts, stearic acid 0.5 parts, matting agent 5 parts, polyethylene wax 1 part, polyamide wax 1 part, antifoaming agent 1 part, polytetrafluoroethylene wax 1 part, 1 part charge regulator, 1 part organic bentonite, 2 parts catalyst, 40 parts zinc powder, 4 parts cellulose acetate-butyrate, 4 parts floating flower agent.

[0054] The epoxy resin is E-12 and novolac epoxy resin with a weight ratio of 4:1.

[0055] The curing agent is a novolac resin.

[0056] The catalyst is an imidazole derivative.

[0057] The defoamer is a mixture of 70 parts by weight of amide wax, 10 parts by weight of stearic acid, 20 parts by weight of benzoin, and 20 parts by weight of PE wax.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com