Waterproof and anticorrosive paint for helicopter and preparation method of waterproof and anticorrosive paint

An anti-corrosion coating and helicopter technology, applied in the field of coatings, can solve problems such as damaging aircraft structures, corroding aircraft surfaces, and affecting flight safety, achieving good water resistance and adhesion, preventing corrosion, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

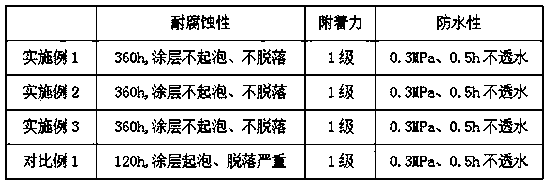

Examples

Embodiment 1

[0021] The waterproof and anticorrosion coating for helicopters comprises the following components in parts by weight: 36 parts of epoxy acrylic resin, 22 parts of isocyanate, 28 parts of butyl acetate, 16 parts of dibutyl benzoate, 21 parts of organic solvent, polytetrafluoroethylene 13 parts, polyethylene 15 parts, neodymium fluoride 17 parts, gadolinium fluoride 13 parts, sodium oxide 15 parts, triethanolamine 18 parts, titanium trioxide 11 parts, dibutyltin dilaurate 8 parts, titanium dioxide 6 parts and water 22~34 servings.

[0022] Wherein, the organic solvent comprises the following components in parts by weight: 27 parts of cyclohexanone, 29 parts of ethanol, 13 parts of polyvinyl alcohol and 18 parts of acetone.

[0023] A preparation method for a waterproof and anticorrosion coating for a helicopter comprises the following preparation steps:

[0024] S1. Add cyclohexanone and acetone into the reaction vessel, stir for 10 minutes, add ethanol and polyvinyl alcohol, ...

Embodiment 2

[0031] The waterproof and anticorrosion coating for helicopters comprises the following components in parts by weight: 45 parts of epoxy acrylic resin, 26 parts of isocyanate, 32 parts of butyl acetate, 25 parts of dibutyl benzoate, 27 parts of organic solvent, polytetrafluoroethylene 18 parts, polyethylene 23 parts, neodymium fluoride 24 parts, gadolinium fluoride 22 parts, sodium oxide 15-19 parts, triethanolamine 21 parts, titanium trioxide 15 parts, dibutyltin dilaurate 14 parts, talcum powder 12 parts and 34 parts of water.

[0032] Wherein, the organic solvent includes the following components in parts by weight: 35 parts of cyclohexanone, 42 parts of ethanol, 19 parts of polyvinyl alcohol and 26 parts of acetone.

[0033] A preparation method for a waterproof and anticorrosion coating for a helicopter comprises the following preparation steps:

[0034] S1. Add cyclohexanone and acetone into the reaction vessel, stir for 15 minutes, add ethanol and polyvinyl alcohol, ra...

Embodiment 3

[0041] The waterproof and anticorrosion coating for helicopters comprises the following components in parts by weight: 40 parts of epoxy acrylic resin, 24 parts of isocyanate, 30 parts of butyl acetate, 20 parts of dibutyl benzoate, 24 parts of organic solvent, polytetrafluoroethylene 15 parts, polyethylene 9 parts, neodymium fluoride 21 parts, gadolinium fluoride 18 parts, sodium oxide 17 parts, triethanolamine 19 parts, titanium trioxide 13 parts, dibutyltin dilaurate 11 parts, titanium dioxide 9 parts and water 28 servings.

[0042] Wherein, the organic solvent includes the following components in parts by weight: 31 parts of cyclohexanone, 33 parts of ethanol, 16 parts of polyvinyl alcohol and 22 parts of acetone.

[0043] A preparation method for a waterproof and anticorrosion coating for a helicopter comprises the following preparation steps:

[0044] S1. Add cyclohexanone and acetone into the reaction vessel, stir for 12 minutes, add ethanol and polyvinyl alcohol, rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com