Preparation method for BaTiO2-based ultra-high switch ratio RRAM

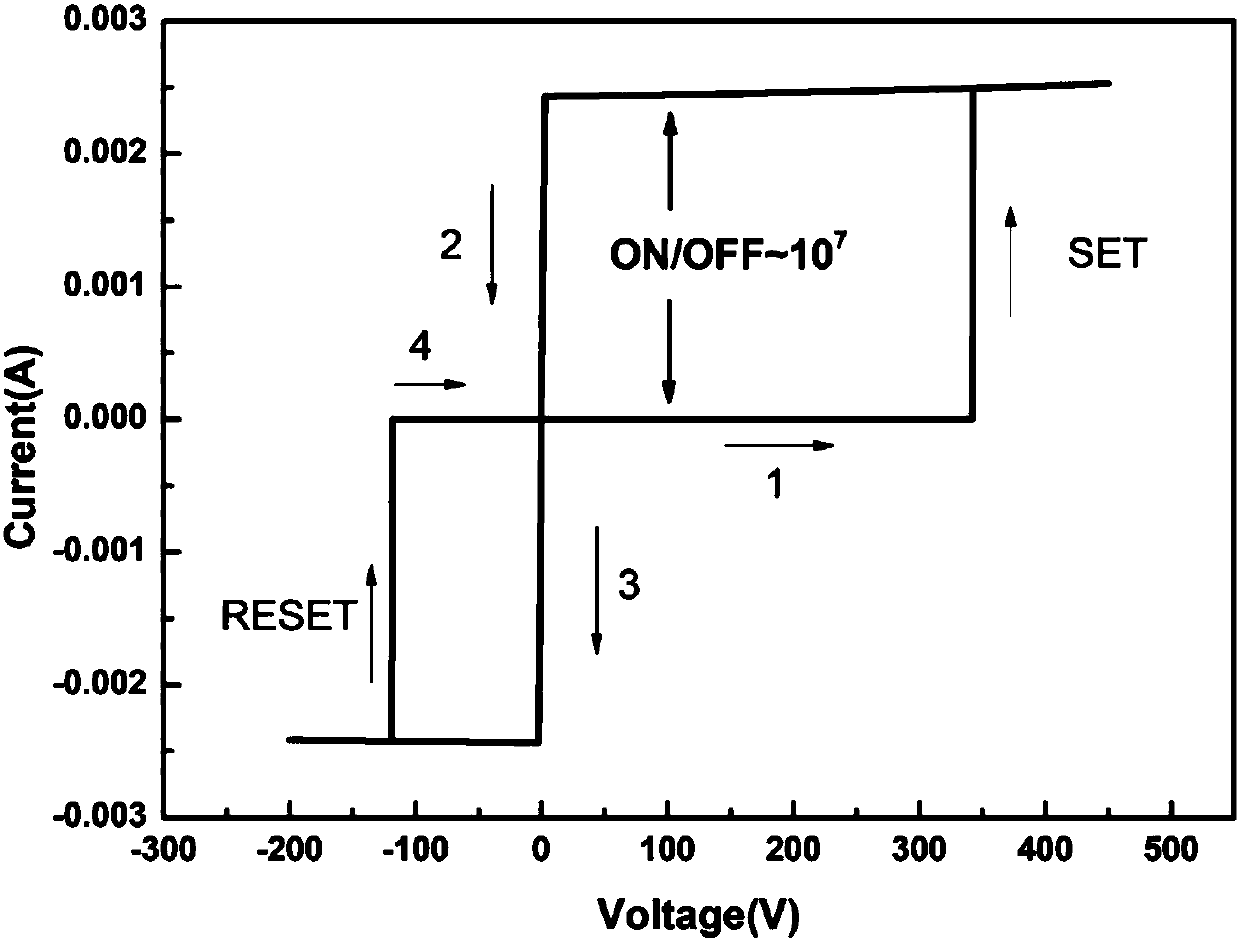

A technology of resistive switching device and on-off ratio is applied in the field of preparation of BaTiO3-based ultra-high on-off ratio resistive switching devices, which can solve the problems of low resistance switching, slow Flash storage operation speed, and complicated preparation process, and achieve ultra-high resistive switching ratio. , good resistance stability, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

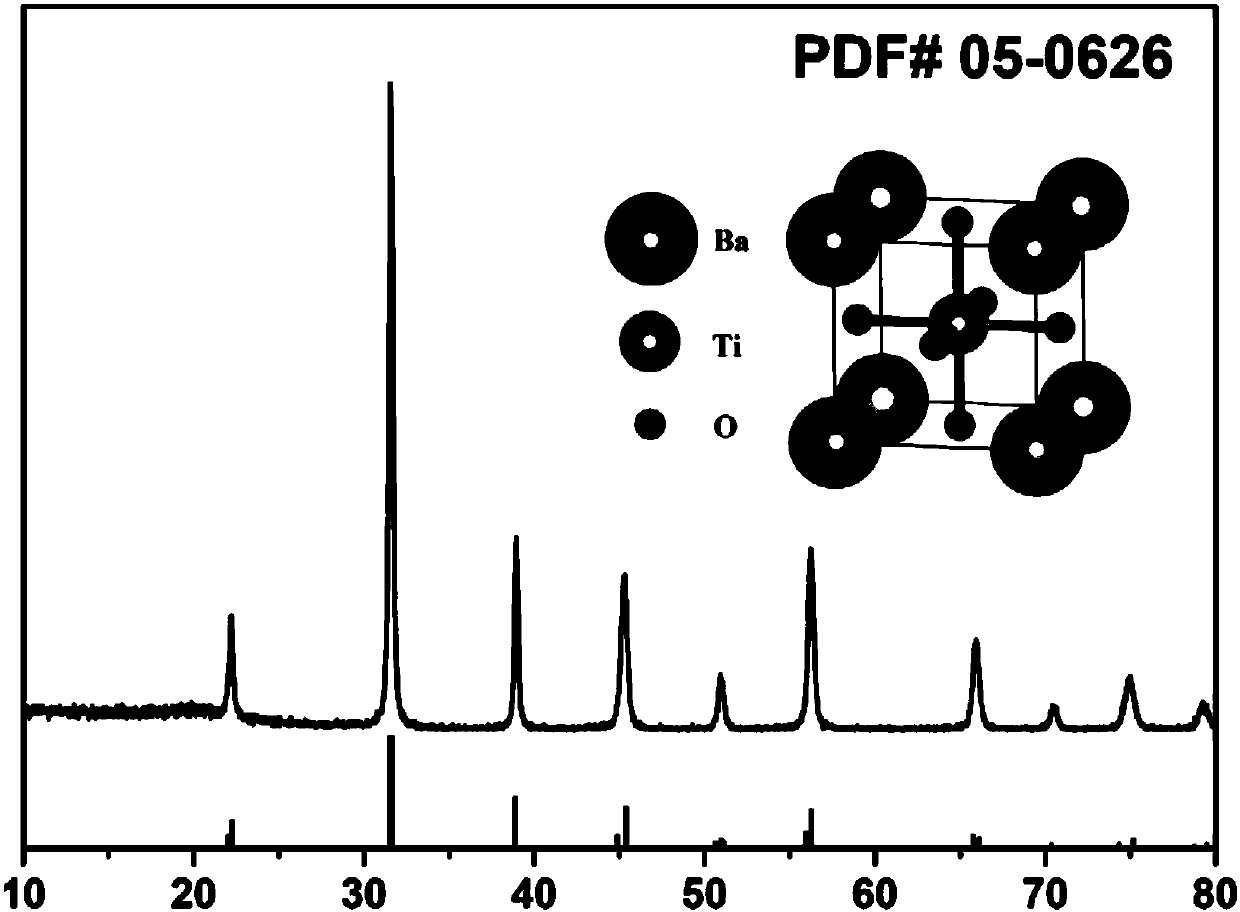

[0024] BaTiO 3 The preparation method of the base ultrahigh switching ratio resistive switch device, the steps are as follows:

[0025] (1) Quartz slices will be selected and ultrasonicated successively with acetone, absolute ethanol, and deionized water. Among them, the size of quartz slices is 10mm*10mm, and ultrasonication is performed for 10 minutes;

[0026] (2) Take Ba(CH 3 COO) 2 The powder was dissolved in a mixed solution of glacial acetic acid and ethylene glycol methyl ether with a volume ratio of 1:1 and stirred to obtain solution A;

[0027] (3) Select Ti(OC 4 h 9 ) 4 The solution was dissolved in a mixed solution of ethanol and lactic acid with a volume ratio of 1:1, and stirred to obtain solution B;

[0028] (4) Dissolve PVP powder in the mixed solution of A and B, and stir in a water bath to obtain solution C;

[0029] (5) Spinning BaTiO on a quartz sheet with a glass rod 3 For micron fiber, the fiber is annealed in a tube furnace at 1100±50°C for 50~70...

Embodiment

[0031] Select a 10mm*10mm quartz plate, and use acetone, absolute ethanol, and deionized water to sonicate for 10 minutes successively; select Ba(CH 3 COO) 2 The powder (5.1g) was dissolved in a mixed solution of 20ml glacial acetic acid and 20ml of ethylene glycol methyl ether, and after stirring for half an hour, solution A was obtained; and Ti(OC 4 h 9 ) 4 The solution (7.4g) was dissolved in a mixed solution of 20ml ethanol and 2ml lactic acid, and stirred for 20 minutes to obtain solution B; then the PVP powder (0.5g) was dissolved in the mixed solution of A and B, and stirred in a water bath at 85°C for 8 hours , to obtain solution C. BaTiO was then spun on a quartz sheet using a glass rod 3 micron fibers, and finally the fibers were annealed in a tube furnace at 1100°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com