Preparation method and system of alum-free vermicelli

A preparation system and technology for vermicelli, applied in the field of preparation of alum-free vermicelli, can solve the problems of inability to large-scale continuous production, scalding of staff, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The utility model will be further described in detail through the embodiments in conjunction with the accompanying drawings.

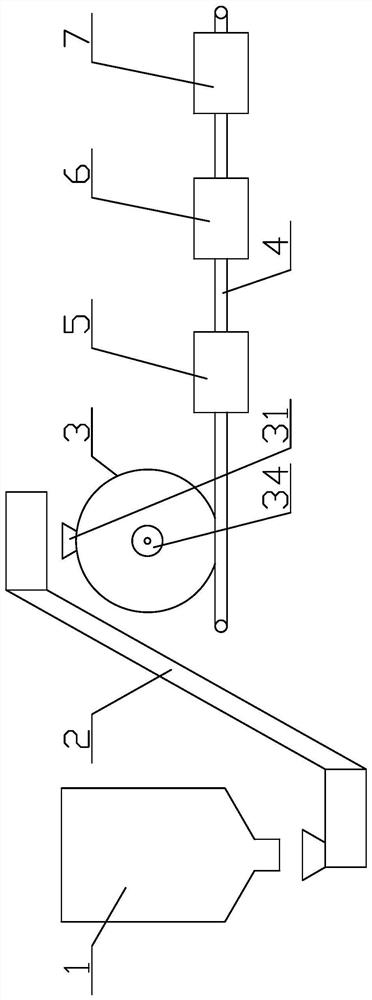

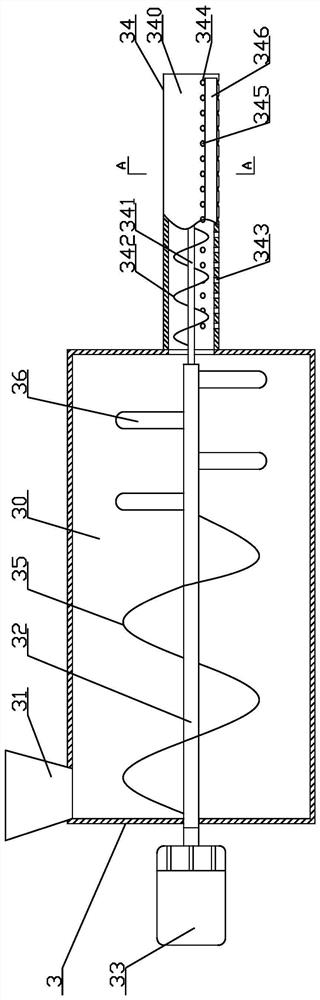

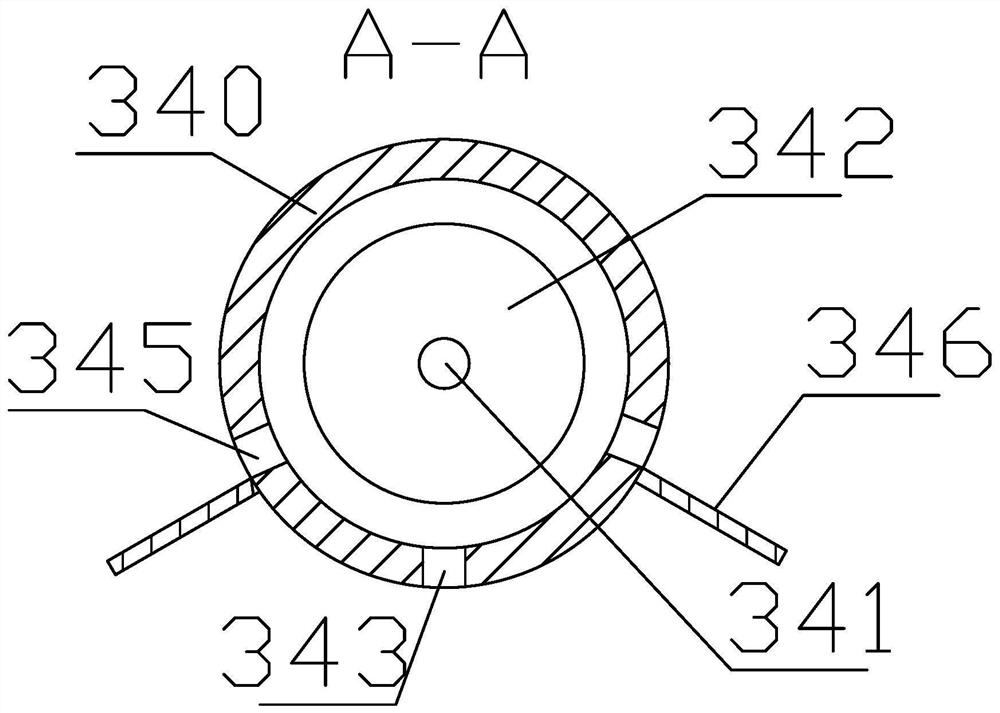

[0027] Such as Figure 1 to Figure 3 Shown, the preparation system of alum-free vermicelli, it comprises the agitator 1 that connects successively, feeder 2, extruder 3 and conveyor belt 4; Pool 7; the electromagnetic wave heating device includes a housing, the inner wall of the housing is provided with a number of electromagnetic heating tubes along the length direction, the two ends of the housing are respectively provided with a material inlet and a material outlet, and the conveyor belt is penetrated by the material inlet and passed through by the material outlet. out. Extrusion molding machine 3 comprises the mixing drum 30 that horizontally arranges, stirring shaft 32, motor 33, extrusion mold 34, helical blade 35 and stirring bar 36; One end is placed on the outside of the mixing drum 30, and is coaxially fixedly connected...

Embodiment 2

[0032] Embodiment 2: the preparation method of vermicelli without alum, utilize the preparation system of vermicelli without alum in embodiment 1 to prepare vermicelli without alum, it comprises the following steps: (1) noodle making; (2) extrusion molding; (3) pregelatinization (4) gelatinization by electromagnetic wave heating; (5) cooling; wherein,

[0033] (1) Noodle making: Pour a certain amount of starch into the mixer 1, then add 40% water of the starch mass, the water temperature is required to be controlled above 83°C, and the starch is stirred until it becomes loose and flocculent to obtain flocculent starch;

[0034] (2) Extrusion molding: After cooling the flocculent starch to 20°C, add it to the extrusion molding machine 3 and extrude to obtain prefabricated vermicelli; wherein, the molding pressure is 6 bar, and the motor speed is 180 rpm.

[0035] (3) pre-gelatinization: put the pre-gelatinized vermicelli into the pre-gelatinization boiling water pool 5 and boil...

Embodiment 3

[0038] Embodiment 3: the preparation method of no alum vermicelli, utilize the preparation system of embodiment 1 no alum vermicelli to prepare no alum vermicelli, it comprises the following steps: (1) noodle making; (2) extrusion molding; (3) pregelatinization (4) gelatinization by electromagnetic wave heating; (5) cooling; wherein,

[0039] (1) Noodle making: Pour a certain amount of starch into mixer 1, then add water with 65% of the starch mass, the water temperature is required to be controlled above 83°C, and the starch is stirred until it becomes loose and flocculent to obtain flocculent starch;

[0040] (2) Extrusion molding: After cooling the flocculent starch to 58°C, add it to the extrusion molding machine 3 and extrude to obtain prefabricated vermicelli; wherein, the molding pressure is 10 bar, and the motor speed is 260 rpm.

[0041] (3) pre-gelatinization: put the formed pre-gelatinized vermicelli into the pre-gelatinization boiling water pool 5 and boil for 3 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com