Preparation method for Sincalide

A mass percent, ammonia water technology, applied in the field of polypeptide drug preparation, can solve the problems of difficult removal of reagents, unsatisfactory yield, unstable product performance, etc., to reduce pressure, simplify operation steps, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

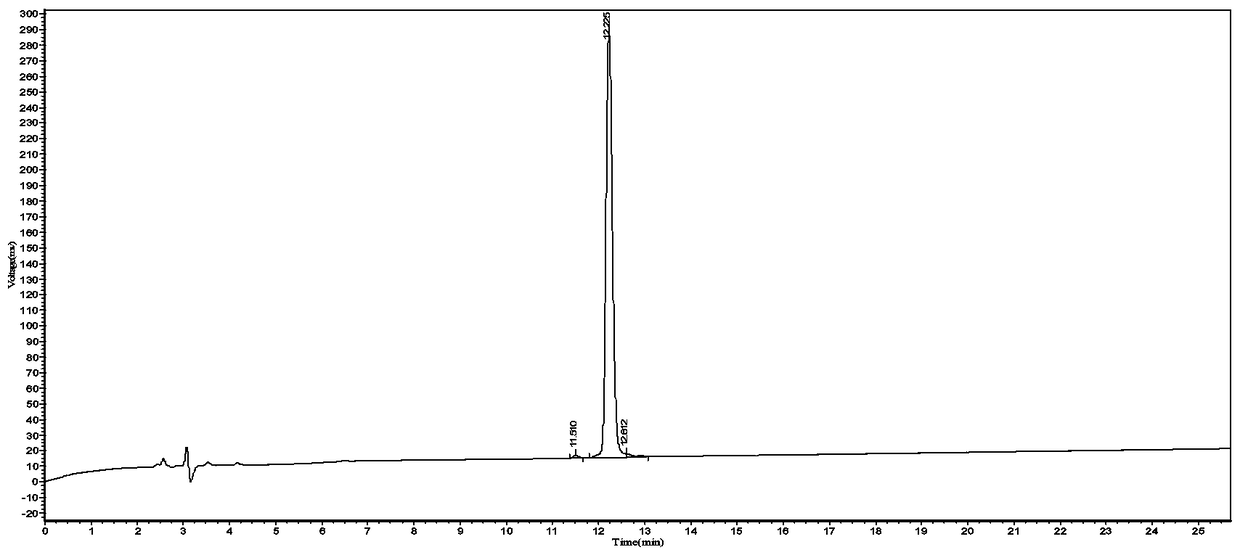

Embodiment 1

[0026] 1. Desalting of crude samples

[0027] (1) Fully dissolve 5 g of the crude peptide obtained by solid-phase synthesis with 500 ml of ammonia water with a concentration of 1% by mass, and set aside;

[0028] (2) First use a glass column with a diameter of 2cm. Fill the upper layer with 300g of polystyrene matrix, and the lower layer with 100g of C18 silica gel matrix, soak the entire matrix with methanol, and set aside;

[0029] (3) Connect the glass column to the high-pressure pump, and adjust the flow rate of the high-pressure pump to 5ml / min;

[0030] (4) The mass percentage concentration of the proportioned acetic acid aqueous solution is 0.15%, and the volume is 500ml;

[0031] (5) First extract all the methanol solution from the matrix, pour the crude product dissolved in 1% ammonia solution into the glass column, adjust the flow rate of the high-pressure pump to 5ml / min until the crude product liquid penetrates the flat top matrix, Add 500ml of acetic acid water...

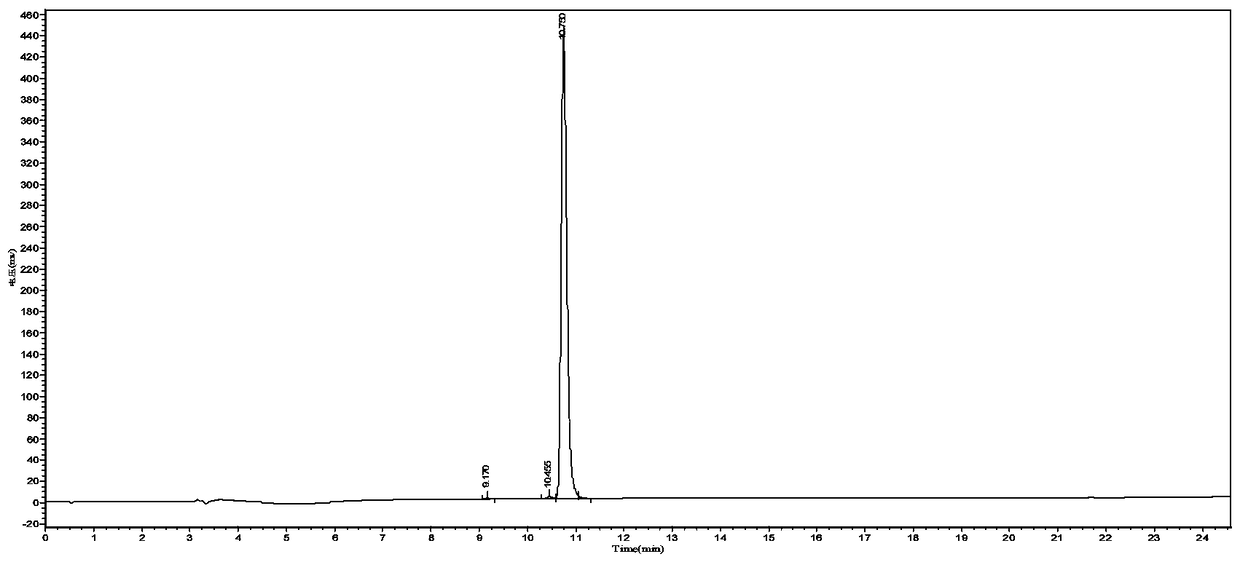

Embodiment 2

[0039] 1. Desalting of crude samples

[0040] (1) Fully dissolve 5 g of the crude peptide obtained by solid-phase synthesis in 500 ml of ammonia water with a concentration of 1.2% by mass, and set aside;

[0041] (2) First use a glass column with a diameter of 2cm. Fill the upper layer with 350g of polystyrene substrate, and the lower layer with 150g of C18 silica gel substrate, soak the entire substrate with methanol, and set aside;

[0042] (3) Connect the glass column to the high-pressure pump, and adjust the flow rate of the high-pressure pump to 6.5ml / min;

[0043] (4) The mass percent concentration of the proportioned acetic acid aqueous solution is 0.18%, and the volume is 500ml;

[0044] (5) First extract all the methanol solution from the matrix, pour the crude product dissolved in 1% ammonia solution into the glass column, adjust the flow rate of the high-pressure pump to 6.5ml / min until the crude product liquid penetrates the flat top matrix , add 500ml acetic ac...

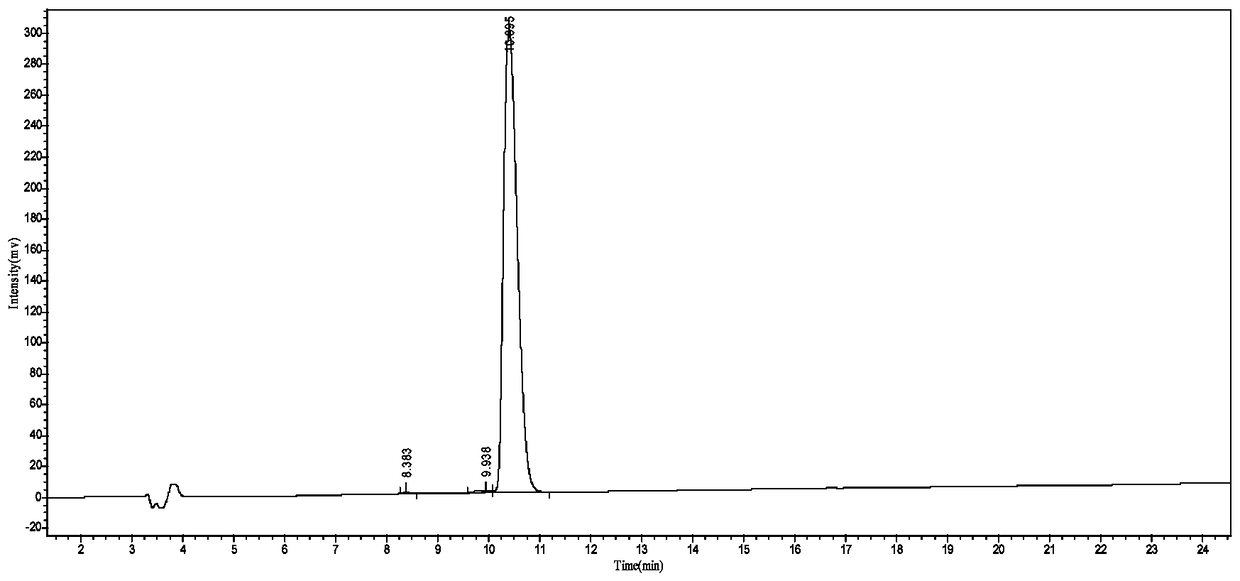

Embodiment 3

[0052] 1. Desalting of crude samples

[0053] (1) Fully dissolve 10 g of the crude peptide obtained by solid-phase synthesis with 800 ml of ammonia water with a concentration of 1.7% by mass, and set aside;

[0054] (2) First use a stainless steel column with a diameter of 3cm. Fill the upper layer with 450g of polystyrene matrix, and the lower layer with 200g of C18 silica gel matrix, soak the entire matrix with methanol, and set aside;

[0055] (3) Connect the glass column to the high-pressure pump, and adjust the flow rate of the high-pressure pump to 10.5ml / min;

[0056] (4) The mass percent concentration of the proportioned acetic acid aqueous solution is 0.2%, and the volume is 800ml;

[0057] (5) First extract all the methanol solution from the matrix, pour the crude product dissolved in 1.5% ammonia solution into the glass column, adjust the flow rate of the high-pressure pump to 10.5ml / min until the crude product liquid penetrates the flat top matrix , add 800ml of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com