Preparation method of flame-retardant cable material

A technology for flame-retardant cable materials and preparation steps, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., which can solve the problems of poor carbonization ability and easy burning of cable material matrix resin, and achieve low crystallinity and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

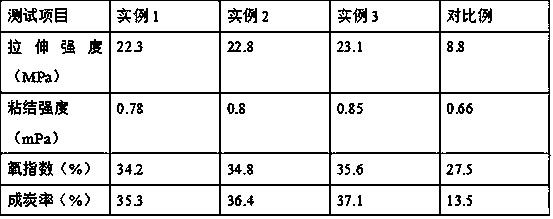

Examples

example 1

[0026] Mix 400mL of sodium hydroxide solution with a mass fraction of 40% and 80g of aluminum hydroxide, place in a stainless steel pot, heat up to 200°C through a resistance furnace, and cook for 20 minutes to obtain a cooking liquid, which is filtered with a microporous membrane. Remove the solid residue to obtain a sodium aluminate solution; mix the aluminum sulfate solution with a mass fraction of 30% and the above-mentioned sodium aluminate solution in an equal volume ratio, add it to a beaker, heat the beaker in a water bath to 70°C, stir for 10 minutes, and keep warm React for 30 minutes to obtain a reaction product, place the reaction product in a high-speed centrifuge and centrifuge at a speed of 4500r / min for 15 minutes, separate and remove the upper layer to obtain a lower sediment, wash the sediment with water until the washing liquid is neutral, and obtain a supernatant Refined aluminum hydroxide; put ultra-fine aluminum hydroxide in an oven, heat up to 80°C, and d...

example 2

[0028]Mix 450mL of sodium hydroxide solution with a mass fraction of 40% and 85g of aluminum hydroxide, place in a stainless steel pot, heat up to 215°C in a resistance furnace, and cook for 23 minutes to obtain a cooking liquid, which is filtered with a microporous membrane. Remove the solid residue to obtain a sodium aluminate solution; mix the aluminum sulfate solution with a mass fraction of 30% and the above sodium aluminate solution in an equal volume ratio, add it to a beaker, heat the beaker in a water bath to 73°C, stir for 13 minutes, and keep warm React for 33 minutes to obtain a reaction product, place the reaction product in a high-speed centrifuge and centrifuge at a speed of 4650r / min for 17 minutes, separate and remove the upper layer to obtain a lower sediment, wash the sediment with water until the washing liquid is neutral, and obtain a supernatant Refined aluminum hydroxide; put ultra-fine aluminum hydroxide in an oven, heat up to 83°C, and dry for 4.5 hours...

example 3

[0030] Mix 500mL of sodium hydroxide solution with a mass fraction of 40% and 90g of aluminum hydroxide, place in a stainless steel pot, heat up to 230°C through a resistance furnace, and cook for 25min to obtain a cooking liquid, which is filtered with a microporous membrane. Remove the solid residue to obtain a sodium aluminate solution; mix the aluminum sulfate solution with a mass fraction of 30% and the above-mentioned sodium aluminate solution in an equal volume ratio, add it to a beaker, heat the beaker in a water bath to 75°C, stir for 15 minutes, and keep warm React for 35 minutes to obtain the reaction product, place the reaction product in a high-speed centrifuge and centrifuge at a speed of 4800r / min for 20 minutes, separate and remove the supernatant to obtain the lower sediment, wash the sediment with water until the washing liquid is neutral, and obtain a supernatant Refined aluminum hydroxide; put ultra-fine aluminum hydroxide in an oven, heat up to 85°C, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com