A kind of glass fiber reinforced hot-melt adhesive bonding resin and preparation method thereof

A bonding resin and hot-melt adhesive technology, applied in the field of bonding resin, can solve problems such as large fluctuations in peeling force value, high cost of reaction kettle, uneven glue-hanging interface, etc., to achieve improved softening point, low cost, and improved compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

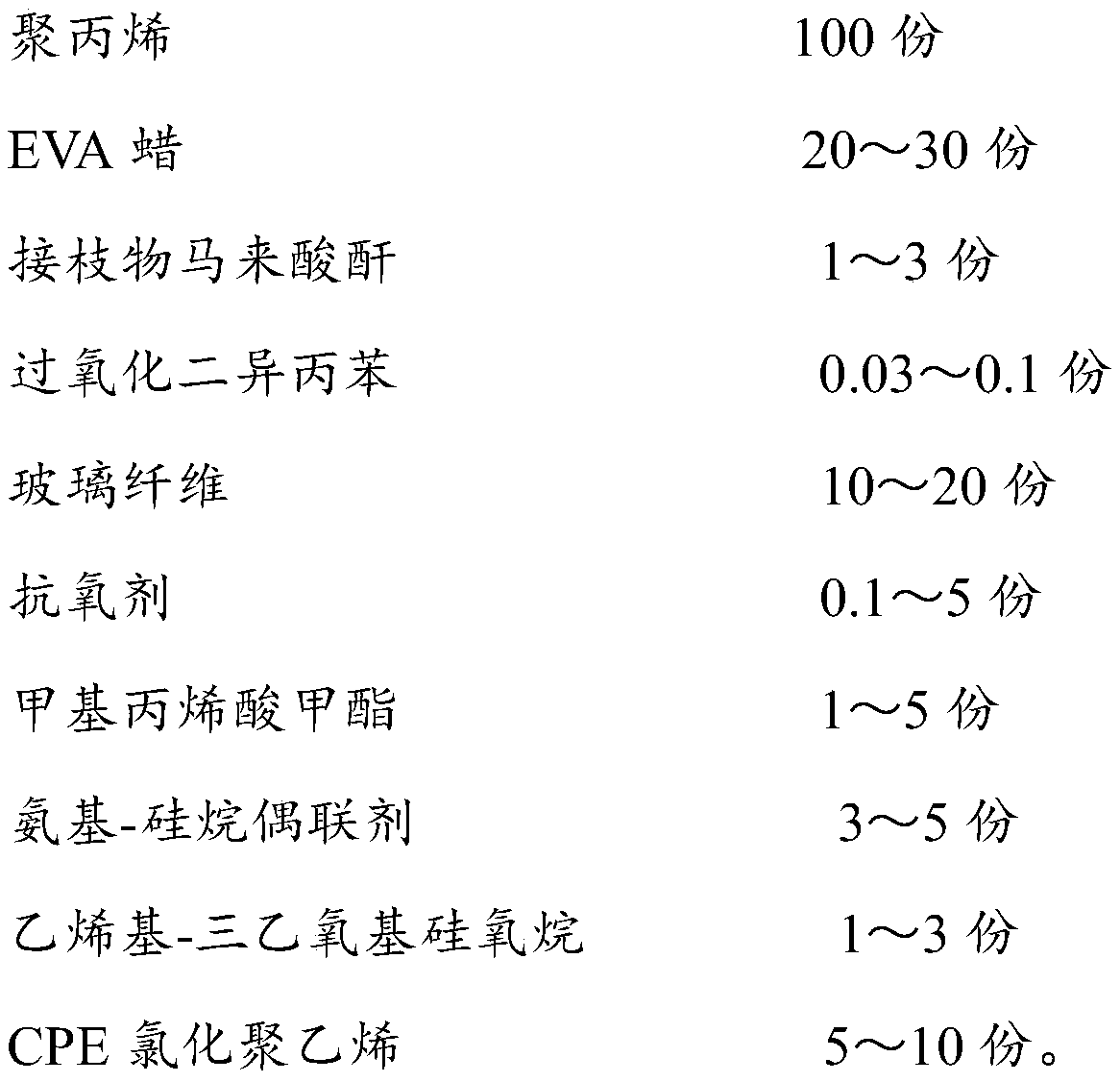

[0021] A glass fiber reinforced hot melt adhesive bonding resin:

[0022]

[0023]

[0024] First put the grafted maleic anhydride in a 1L beaker and heat it on a heating mantle to become a liquid, then mix the polypropylene, EVA wax, and the initiator dicumyl peroxide at a high speed, and mix well; then mix the above evenly The masterbatch, methyl methacrylate, antioxidant, CPE chlorinated polyethylene and other materials are put into the discharge port of the twin-screw extruder according to the above ratio, and let it run in the preheating and conveying area of the twin-screw extruder ( Zone 1 180°C and Zone 2 180°C), and then pass through the melting zone (3 zone 190°C) to make it completely melted, then add amino-siloxane coupling agent and compatibilizer vinyl- Triethoxysiloxane, chopped glass fibers heated in an oven at 180°C, and the molten material added to the first feeding port are mixed (190°C in zone 4), 200°C in zone 5, and 200°C in zone 6 , The temperat...

Embodiment 2

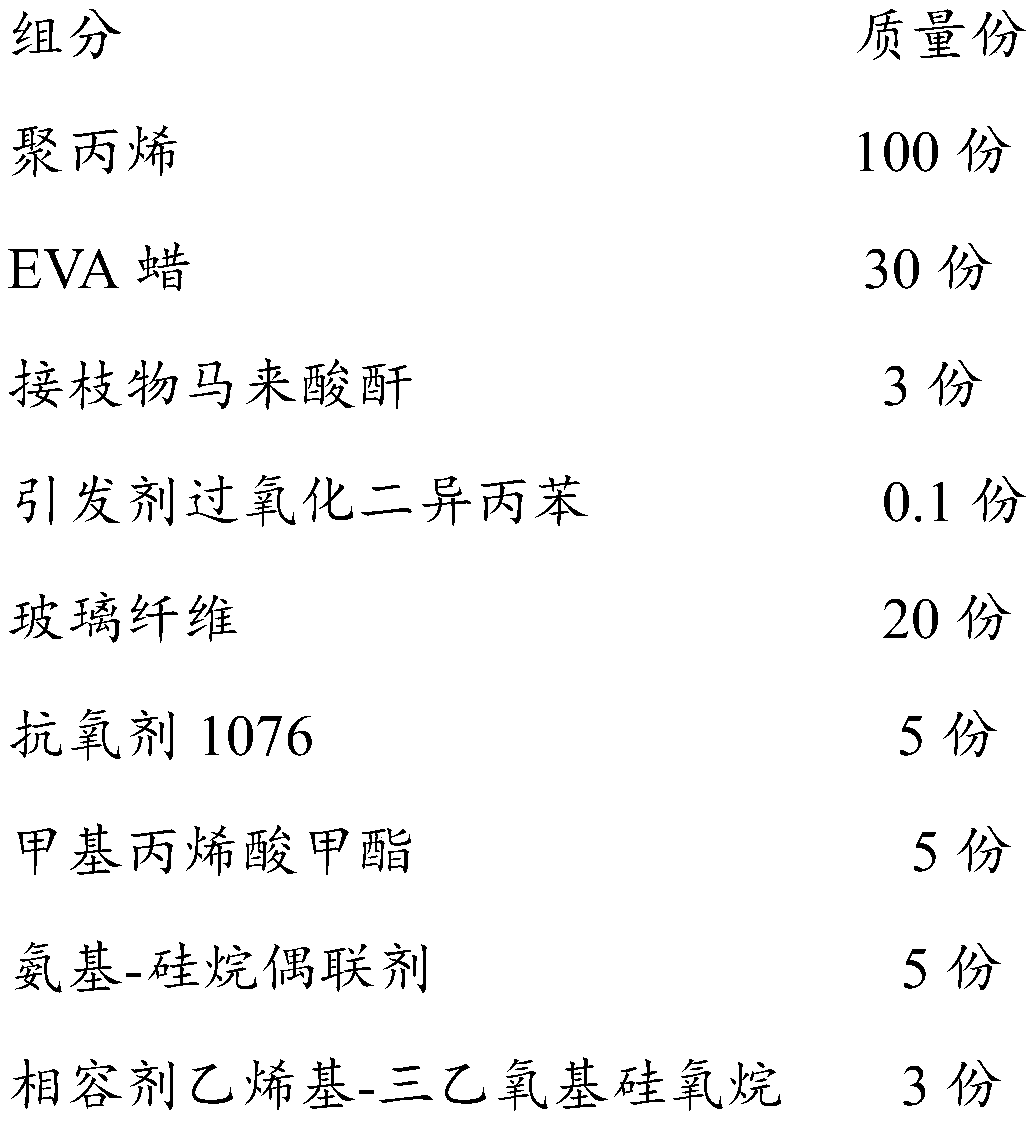

[0026] A glass fiber reinforced hot melt adhesive bonding resin:

[0027]

[0028]

[0029] First put the grafted maleic anhydride in a 1L beaker and heat it on a heating mantle to become a liquid, then mix the polypropylene, EVA wax, and the initiator dicumyl peroxide at a high speed, and mix well; then mix the above evenly The masterbatch, methyl methacrylate, antioxidant, CPE chlorinated polyethylene and other materials are put into the discharge port of the twin-screw extruder according to the above ratio, and let it run in the preheating and conveying area of the twin-screw extruder ( Zone 1 180°C and Zone 2 180°C), and then pass through the melting zone (3 zone 190°C) to make it completely melted, then add amino-siloxane coupling agent and compatibilizer vinyl- Triethoxysiloxane, chopped glass fibers heated in an oven at 180°C, and the molten material added to the first feeding port are mixed (190°C in zone 4), 200°C in zone 5, and 200°C in zone 6 , The temperat...

Embodiment 3

[0031] A glass fiber reinforced hot melt adhesive bonding resin:

[0032]

[0033]

[0034] First put the grafted maleic anhydride in a 1L beaker and heat it on a heating mantle to become a liquid, then mix the polypropylene, EVA wax, and the initiator dicumyl peroxide at a high speed, and mix well; then mix the above evenly The masterbatch, methyl methacrylate, antioxidant, CPE chlorinated polyethylene and other materials are put into the discharge port of the twin-screw extruder according to the above ratio, and let it run in the preheating and conveying area of the twin-screw extruder ( Zone 1 180°C and Zone 2 180°C), and then pass through the melting zone (3 zone 190°C) to make it completely melted, then add amino-siloxane coupling agent and compatibilizer vinyl- Triethoxysiloxane, chopped glass fibers heated in an oven at 180°C, and the molten material added to the first feeding port are mixed (190°C in zone 4), 200°C in zone 5, and 200°C in zone 6 , The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com