Camellia oleifera meal polypeptide, preparation method and effect of promoting estrus and conception in anestrous cows

A technology of camellia oleifera meal polypeptide and cow, which is applied in the field of animal husbandry, can solve the problems such as the in-depth development report of hydrolyzed polypeptide of camellia oleifera meal, and achieves the effect of realizing waste reuse, simple preparation method and increasing economic added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

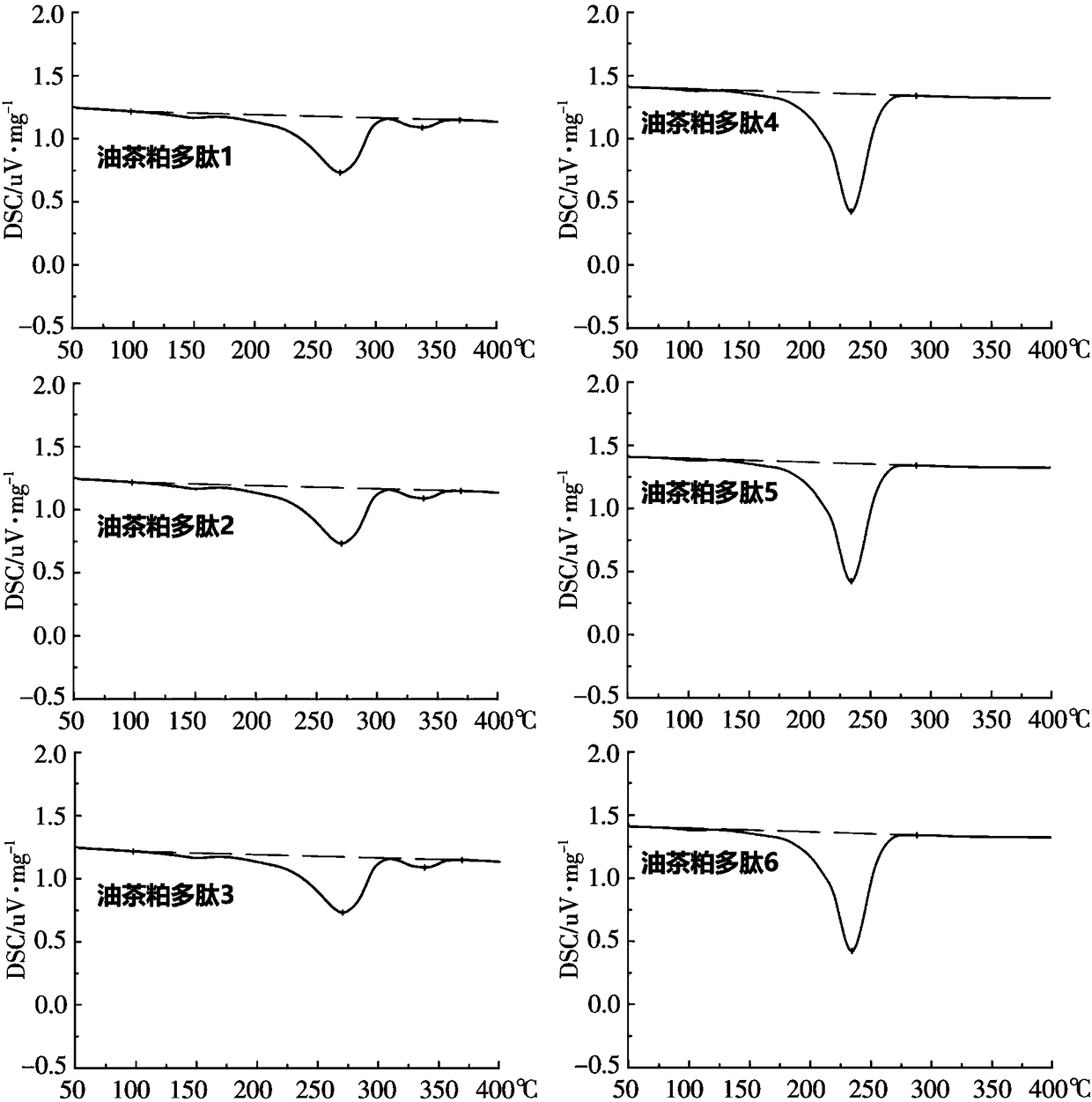

[0046] Example 1: Preparation of camellia oleifera meal polypeptide 1 by trypsin

[0047] Including the following steps:

[0048] Step S1, pulverize the small fruit oil tea meal to 80-100 mesh, add water to soak overnight, and finally make a meal powder suspension, the mass concentration of the meal powder suspension is 150g / L;

[0049] Step S2, adding trypsin for enzymatic hydrolysis (the added weight is 3.0g / 100g based on the weight of meal powder), the enzymatic hydrolysis conditions are: pH value, 8.0; enzymatic hydrolysis temperature, 45°C; enzymatic hydrolysis time, 11 hours; end of enzymatic hydrolysis Afterwards, heat treatment at 90°C for 10 minutes to inactivate trypsin, cool to room temperature, let stand to take the supernatant;

[0050] Step S3, filtering the supernatant with absorbent cotton for 3 times, collecting and merging the filtrate, and freeze-drying to obtain a crude freeze-dried powder;

[0051] Step S4, dissolve the crude freeze-dried powder with ult...

Embodiment 2

[0052] Example 2: Preparation of camellia oleifera meal polypeptide 2 by trypsin

[0053] Including the following steps:

[0054] Step S1, pulverize the small fruit oil tea meal to 80-100 mesh, add water to soak overnight, and finally make a meal powder suspension, the mass concentration of the meal powder suspension is 130g / L;

[0055] Step S2, adding trypsin for enzymatic hydrolysis (the added weight is 2.5g / 100g based on the weight of meal powder), the enzymatic hydrolysis conditions are: pH value, 7.8; enzymatic hydrolysis temperature, 43°C; enzymatic hydrolysis time, 12 hours; end of enzymatic hydrolysis Afterwards, heat treatment at 90°C for 10 minutes to inactivate trypsin, cool to room temperature, let stand to take the supernatant;

[0056] Step S3, filtering the supernatant with absorbent cotton for 3 times, collecting and merging the filtrate, and freeze-drying to obtain a crude freeze-dried powder;

[0057] Step S4, the crude freeze-dried powder is dissolved in u...

Embodiment 3

[0058] Example 3: Preparation of camellia oleifera meal polypeptide 3 by trypsin

[0059] Including the following steps:

[0060]Step S1, pulverize the camellia oleifera meal to 80-100 mesh, add water to soak overnight, and finally prepare a meal powder suspension, and the mass concentration of the meal meal suspension is 170 g / L;

[0061] Step S2, add trypsin for enzymolysis (the added weight is 3.5g / 100g based on the weight of meal meal), and the enzymolysis conditions are: pH value, 8.2; enzymolysis temperature, 47°C; enzymolysis time, 10 hours; enzymolysis end Then, the trypsin was inactivated by high temperature treatment at 90°C for 10 minutes, cooled to room temperature, and the supernatant was taken by standing;

[0062] Step S3, the supernatant is filtered 3 times with absorbent cotton, the combined filtrate is collected, and freeze-dried to obtain crude freeze-dried powder;

[0063] In step S4, the crude freeze-dried powder is dissolved in ultrapure water, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com