Decorating paper and preparation method thereof

A decorative paper and monomer technology, applied in papermaking, paper coating, textiles and papermaking, etc., can solve problems such as insufficient adhesion, water marks on decorative paper, loss of ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

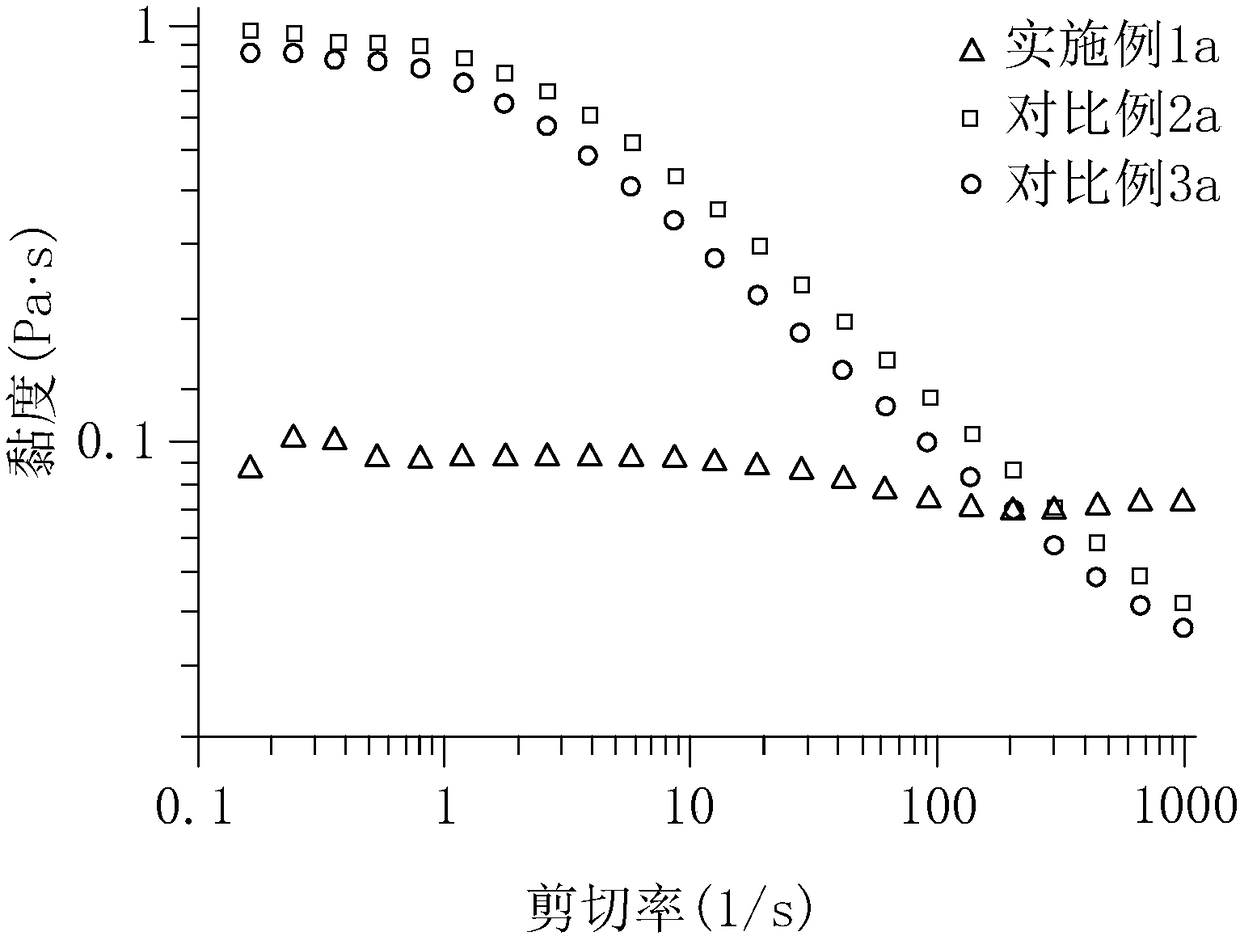

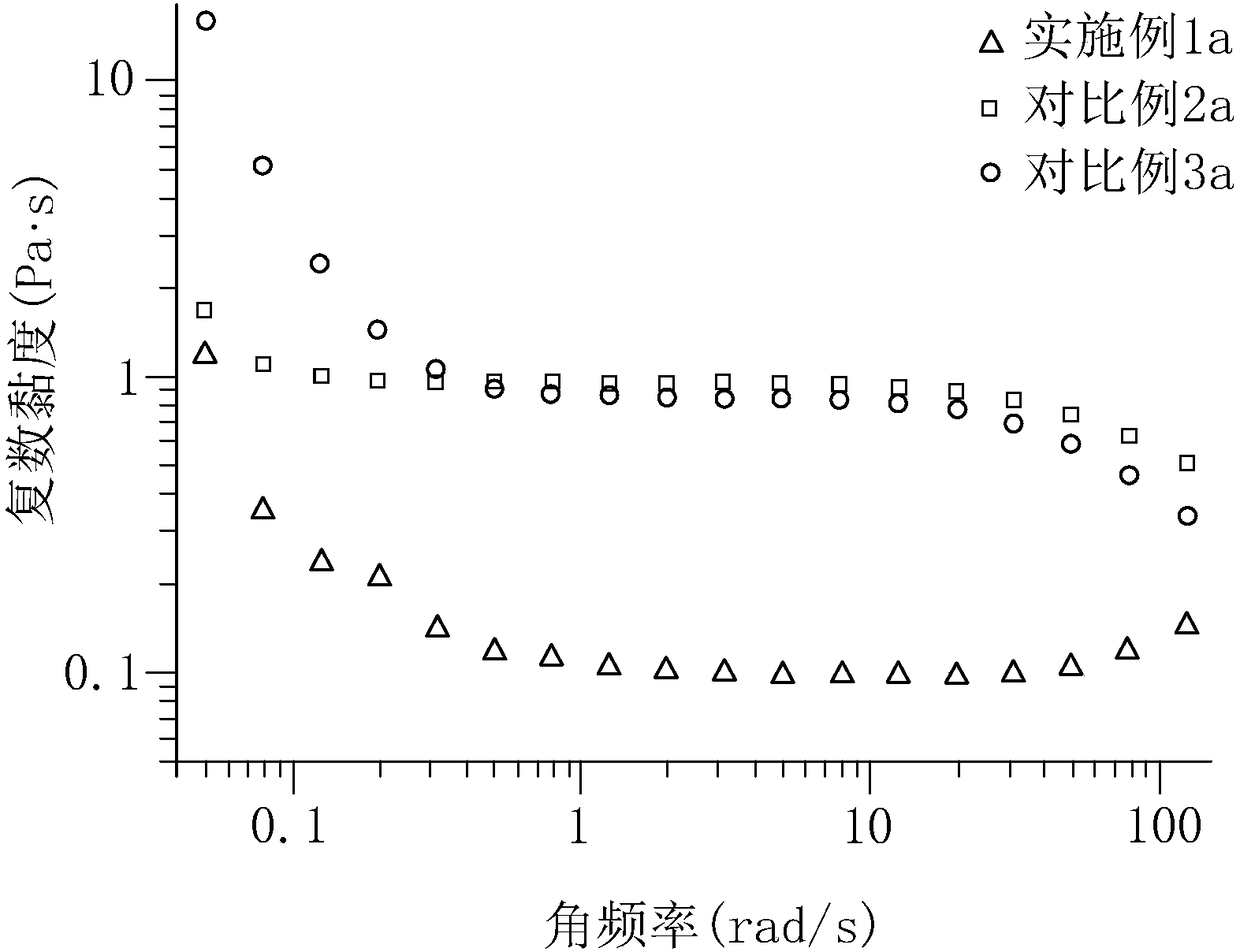

Embodiment 1a

[0028] Preparation of modified polyamide resin: in a nitrogen atmosphere, 31.3g of polyamide resin, 24.5g of n-propanol and 24.5g of absolute ethanol were configured into solution A; 8.0g of methyl methacrylate monomer, 4.8g maleic acid monomer, 4.5g trans-1-octen-1-yl boronic acid monomer and 0.065g dibenzoyl peroxide were made into solution B; 0.005g dibenzoyl peroxide Make solvent C with 4.43g of methyl ethyl ketone; under nitrogen atmosphere and 85°C, add solution B dropwise to solution A for 1 hour, keep warm for 1 hour, then add solution C dropwise three times , with an interval of 1 hour each time, and after the total reaction time reaches 5 hours, the modified polyamide resin is precipitated by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0029] Preparation of water-based ink: mix 40g of modified polyamide resin and 1g of triethylamine evenly, slowly add 5g of water to the aminated resin under ro...

Embodiment 2a

[0031] Preparation of modified polyamide resin: in a nitrogen atmosphere, 28g of polyamide resin, 21g of n-propanol and 28g of absolute ethanol are configured into solution A; 9.0g of methyl methacrylate monomer, 4g of cis-butyl Dibenzoyl peroxide of 0.01 g and dibenzoyl peroxide of 0.01 g and butanone of 4.43 g are made into solvent C: Under the condition of nitrogen atmosphere and 90°C, add solution B dropwise to solution A for 1.5 hours, keep warm for 1.5 hours, then add solution C three times with an interval of 1 hour, the total reaction After the time reaches 6 hours, the modified polyamide resin is precipitated by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0032] Preparation of water-based ink: Mix 45g of modified polyamide resin and 0.5g of triethylamine evenly, slowly add 3g of water to the aminated resin under room temperature and high-speed stirring, and continue stirring at high speed to obta...

Embodiment 3a

[0034] Preparation of modified polyamide resin: in a nitrogen atmosphere, 35g of polyamide resin, 28g of n-propanol and 21g of absolute ethanol were configured into solution A; 7.0g of methyl methacrylate monomer, 6g of cis-butyl Dibenzoyl peroxide of 0.007g dibenzoyl peroxide and 0.007g of dibenzoyl peroxide and 4.43g of methyl ethyl ketone is made into solvent C; Under the condition of atmosphere and 80°C, add solution B dropwise to solution A for 1.25 hours, keep warm for 1.25 hours, then add solution C three times with an interval of 1 hour, and the total reaction time is 5.5 hours Finally, the modified polyamide resin is precipitated out by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0035] Preparation of water-based ink: Mix 55g of modified polyamide resin and 0.75g of triethylamine evenly, slowly add 4g of water to the aminated resin under room temperature and high-speed stirring, and continue st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com