A kind of decorative paper and preparation method thereof

A technology for decorative paper and preparation steps, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of decorative paper water marks, loss of ink, insufficient adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

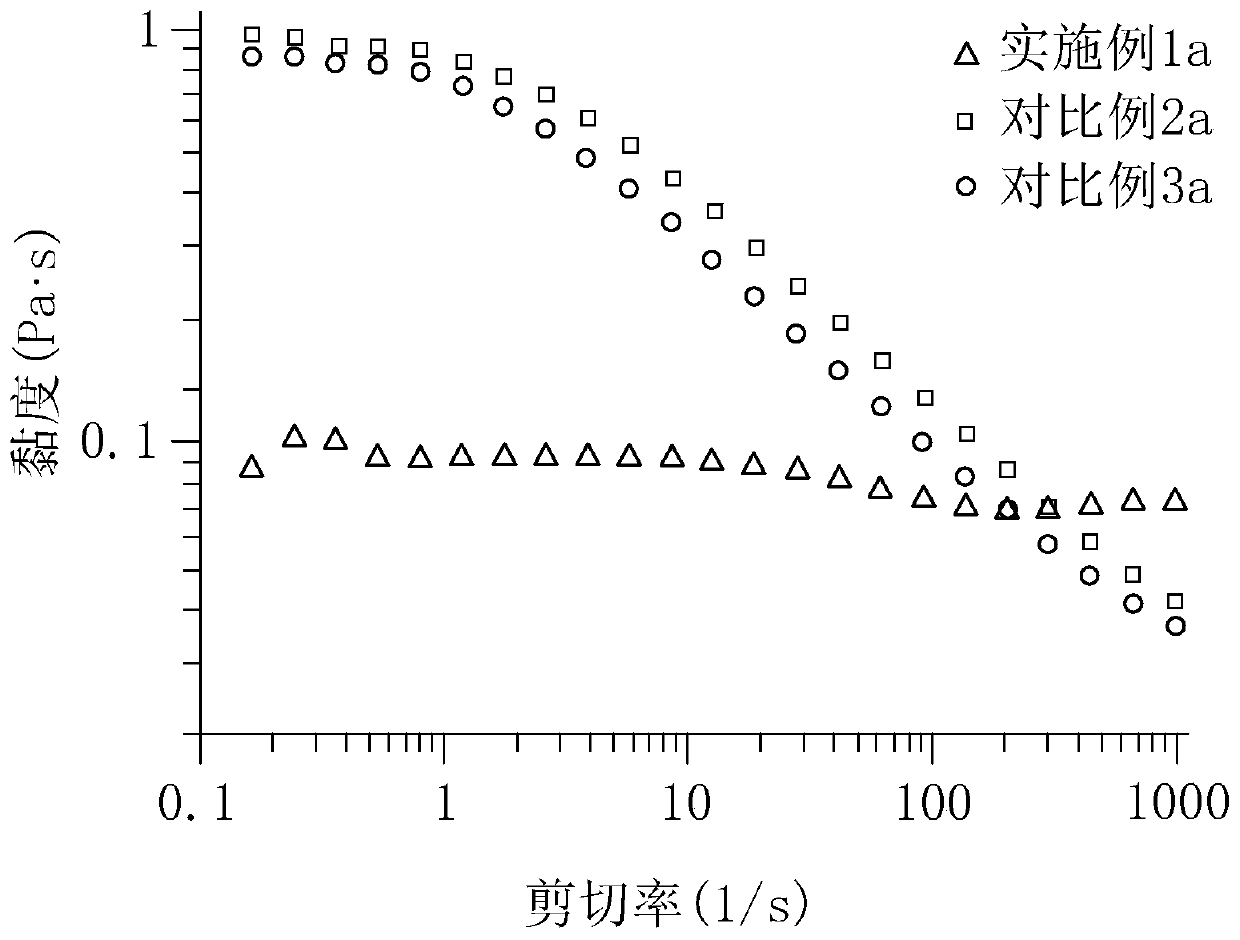

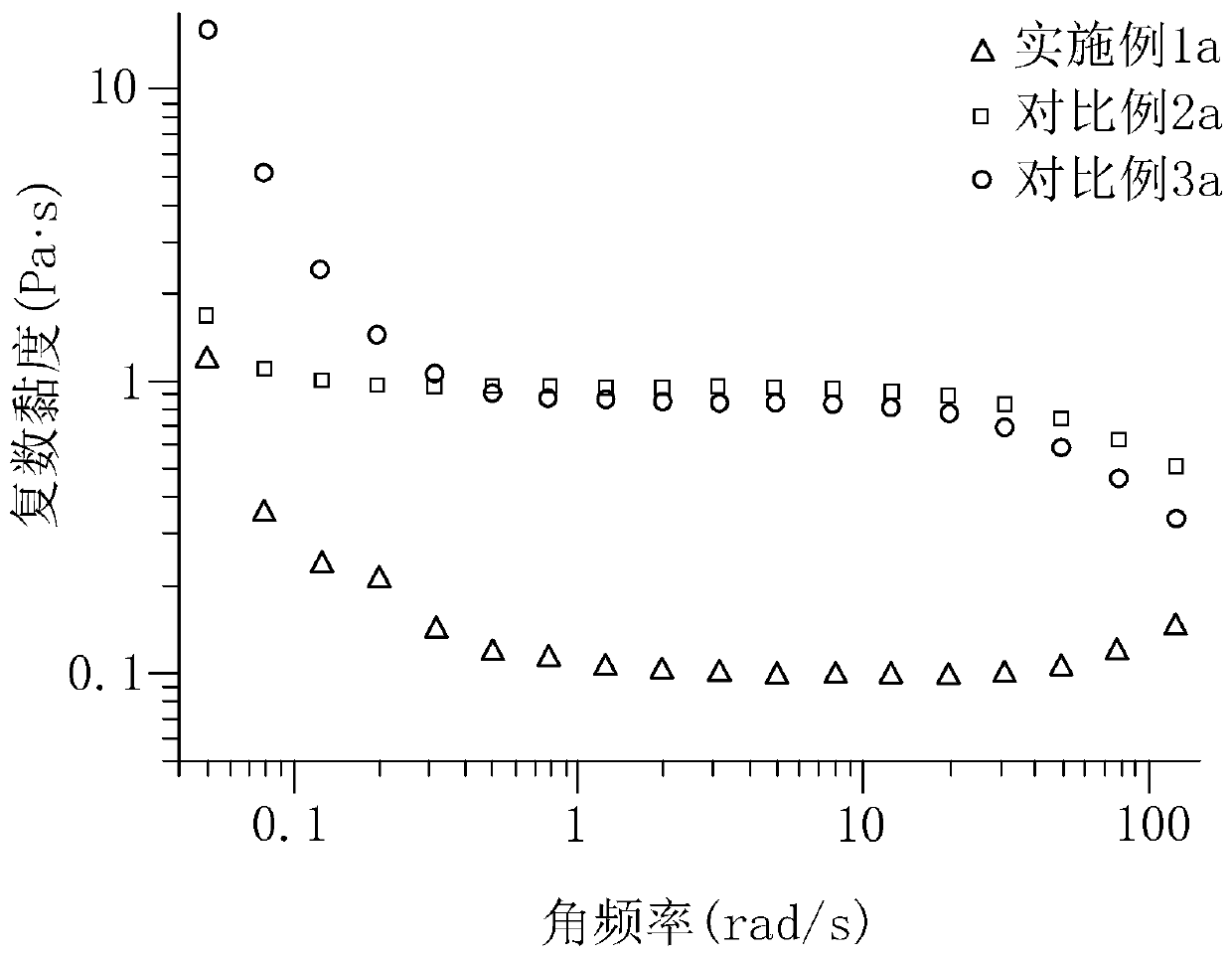

Embodiment 1a

[0028] Preparation of modified polyamide resin: in a nitrogen atmosphere, 31.3g of polyamide resin, 24.5g of n-propanol and 24.5g of absolute ethanol were configured into solution A; 8.0g of methyl methacrylate monomer, 4.8g maleic acid monomer, 4.5g trans-1-octen-1-yl boronic acid monomer and 0.065g dibenzoyl peroxide were made into solution B; 0.005g dibenzoyl peroxide Make solvent C with 4.43g of methyl ethyl ketone; under nitrogen atmosphere and 85°C, add solution B dropwise to solution A for 1 hour, keep warm for 1 hour, then add solution C dropwise three times , with an interval of 1 hour each time, and after the total reaction time reaches 5 hours, the modified polyamide resin is precipitated by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0029] Preparation of water-based ink: mix 40g of modified polyamide resin and 1g of triethylamine evenly, slowly add 5g of water to the aminated resin under ro...

Embodiment 2a

[0031] Preparation of modified polyamide resin: in a nitrogen atmosphere, 28g of polyamide resin, 21g of n-propanol and 28g of absolute ethanol are configured into solution A; 9.0g of methyl methacrylate monomer, 4g of cis-butyl Dibenzoyl peroxide monomer, 5g of 4-vinylbenzeneboronic acid monomer and 0.06g of dibenzoyl peroxide are made into solution B; 0.01g of dibenzoyl peroxide and 4.43g of butanone are made into solvent C: Under the condition of nitrogen atmosphere and 90°C, add solution B dropwise to solution A for 1.5 hours, keep warm for 1.5 hours, then add solution C three times, each interval is 1 hour, the total reaction After the time reaches 6 hours, the modified polyamide resin is precipitated by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0032] Preparation of water-based ink: Mix 45g of modified polyamide resin and 0.5g of triethylamine evenly, slowly add 3g of water to the aminated resin u...

Embodiment 3a

[0034] Preparation of modified polyamide resin: in a nitrogen atmosphere, 35g of polyamide resin, 28g of n-propanol and 21g of absolute ethanol were configured into solution A; 7.0g of methyl methacrylate monomer, 6g of cis-butyl Dibenzoyl peroxide of 0.007g dibenzoyl peroxide and 0.007g of dibenzoyl peroxide and 4.43g of methyl ethyl ketone is made into solvent C; Under the condition of atmosphere and 80°C, add solution B dropwise to solution A for 1.25 hours, keep warm for 1.25 hours, then add solution C three times with an interval of 1 hour, and the total reaction time is 5.5 hours Finally, the modified polyamide resin is precipitated out by precipitation method-flocculation. Wherein the good solvent is n-propanol, and the poor solvent is petroleum ether.

[0035] Preparation of water-based ink: Mix 55g of modified polyamide resin and 0.75g of triethylamine evenly, slowly add 4g of water to the aminated resin under room temperature and high-speed stirring, and continue st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com