Processing method of sapphire sheet product containing ink frame

A sapphire and ink technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficulty in further improving cutting accuracy, large damage to sapphire strength, affecting the quality of sapphire sheet products, and saving machine and labor costs. , the effect of small strength damage and reduction of the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

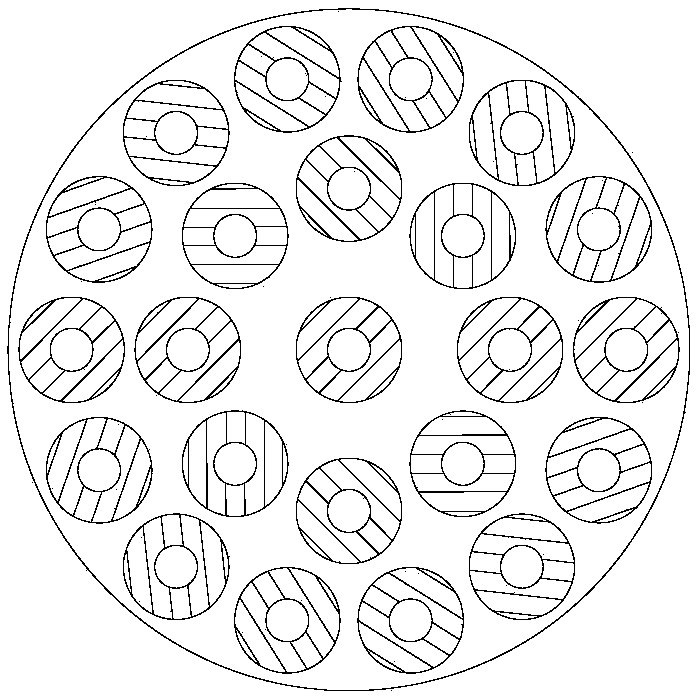

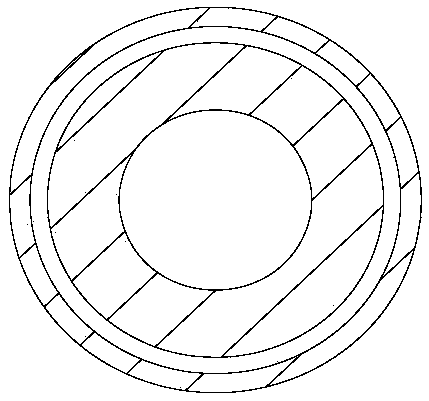

[0032] Step A: First, make a large sapphire substrate, and directly grind and polish it to achieve the required thickness and surface roughness of the finished product. Directly perform screen printing on a large sapphire substrate to obtain multiple ink patterns. The spacing between each pattern is about 1mm, and the screen printing pattern is about 0.5mm larger than the designed finished pattern (the outer radius of the ring is about 0.5mm larger than the finished product). The resulting product is figure 1 shown.

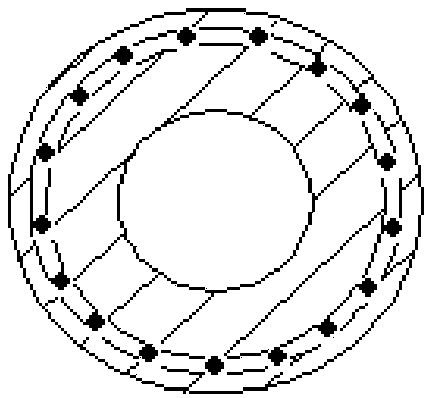

[0033]Step B: Use a carbon dioxide laser and use the CCD (image sensor) positioning method to cut the ink layer into the outline size required by the "finished pattern". The purpose of this step is to cut the ink layer on the ink surface with a uniform line width to ensure the next step PS (picosecond) laser cutting sapphire will not damage the ink layer and cause the ink layer to fall off, resulting in edge burrs, light leakage and other defects. The carbon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com