Heat pump coupled adsorption type closed system for drying sludge

An adsorption drying and adsorption system technology, which is applied in dehydration/drying/concentrated sludge treatment, steam condensation, and separation of dispersed particles, can solve secondary environmental pollution and other problems, reduce operating costs, improve efficiency, and expand the scope of application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

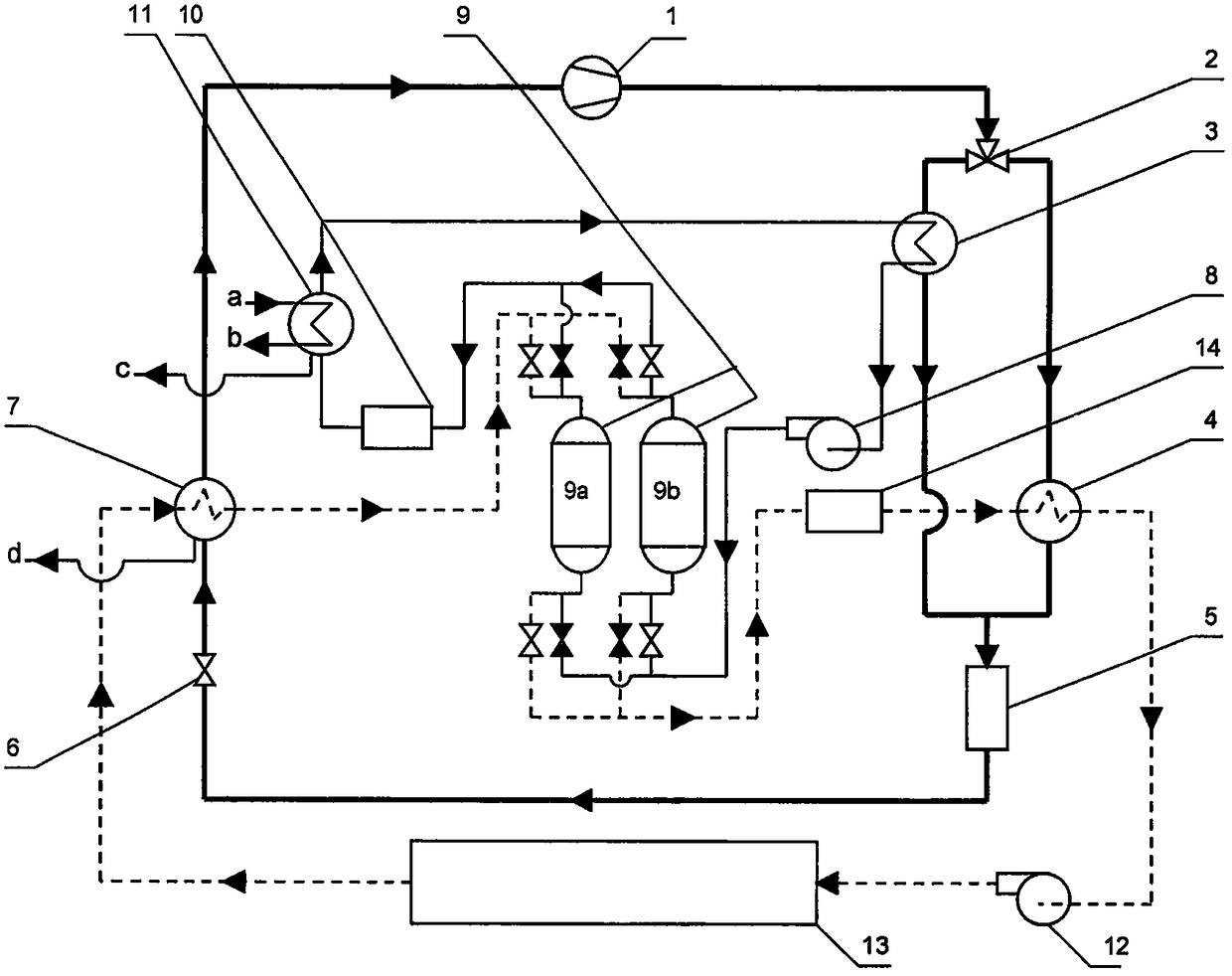

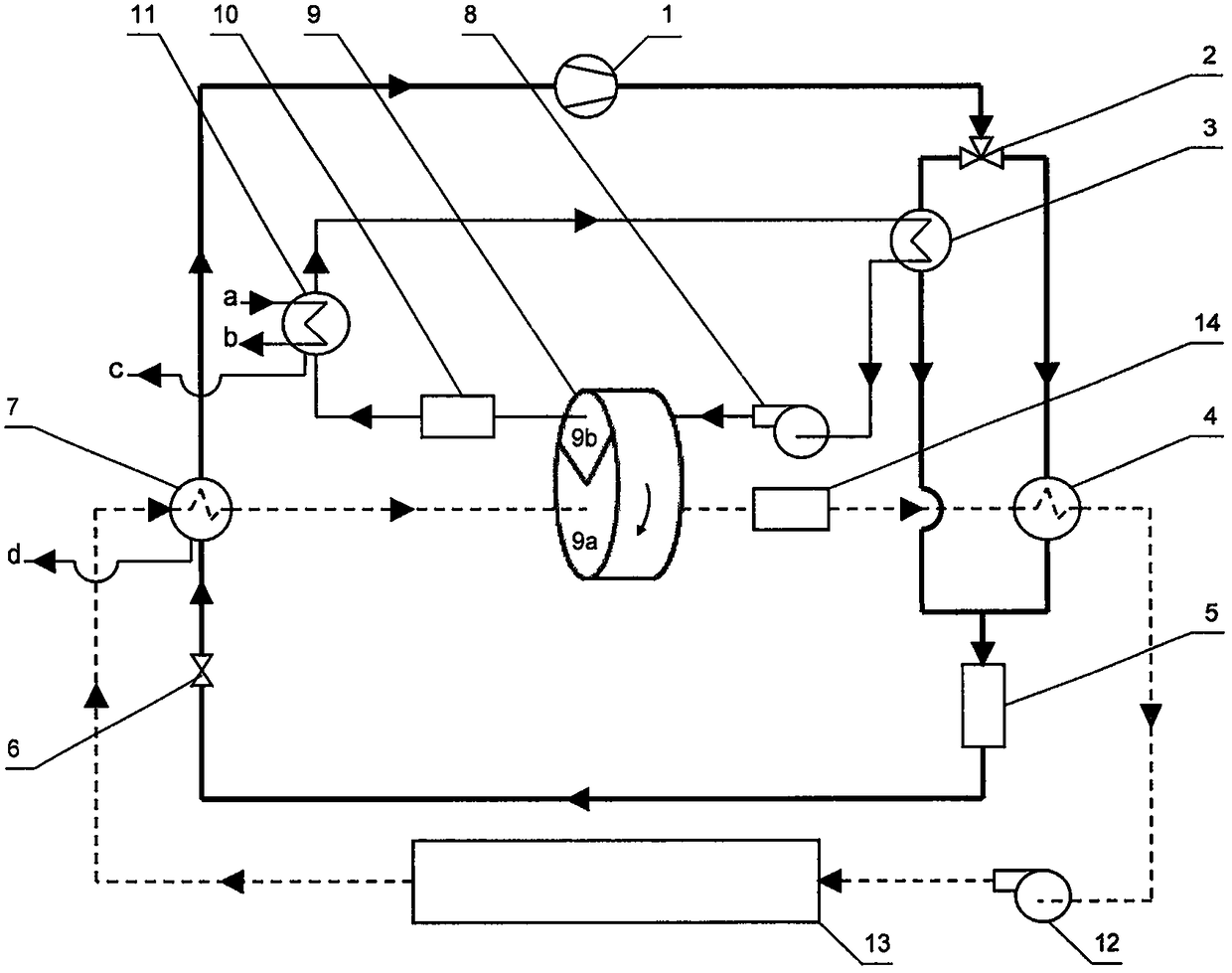

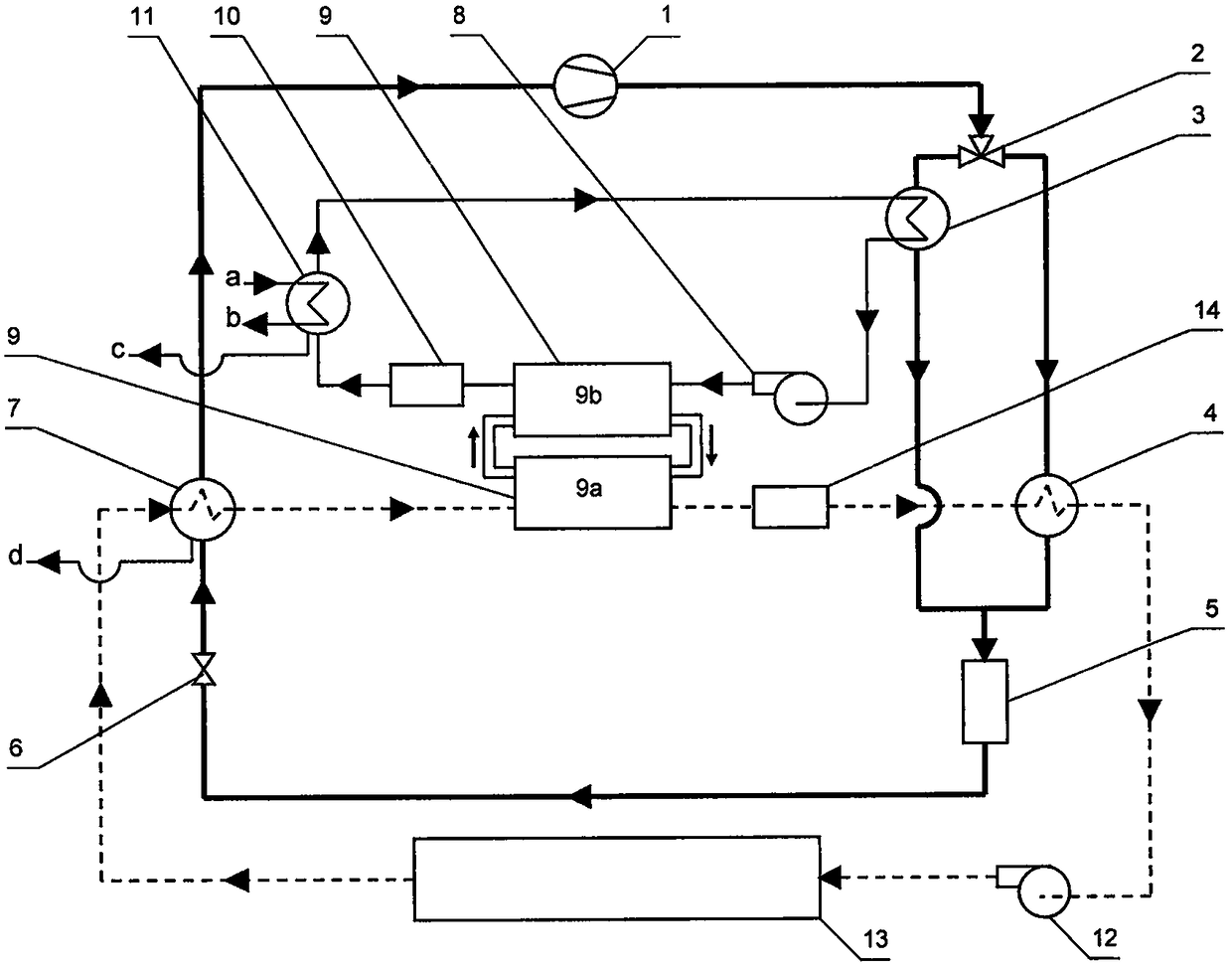

[0033] A heat pump coupled adsorption drying sludge method in this embodiment consists of a heat pump system refrigerant circulation loop, an adsorption system regeneration air circulation loop and an air circulation loop for drying sludge. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] Such as figure 1 , 2 , 3, the thick line represents the refrigerant circulation circuit, the thin line represents the regeneration air circulation circuit, and the dotted line represents the drying air circulation circuit. All three media circulate in a clockwise direction.

[0035] The refrigerant circulation loop includes compressor 1, three-way regulating valve 2, condenser A3, condenser B4, liquid receiver 5, expansion valve 6, and evaporator 7; the refrigerant pipeline at the outlet of compressor 1 passes through the three-way regulating valve 2. Connect with condenser A3 and condenser B4; the pipeline at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com