Method for sludge treating and ferrous metallurgy dust removal through metallurgical sintering process

A technology of iron and steel metallurgy and sludge, which is applied in the field of waste resource utilization, can solve the problems of improper disposal of iron and steel metallurgy dust, and achieve the effect of resource utilization, low FeO, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

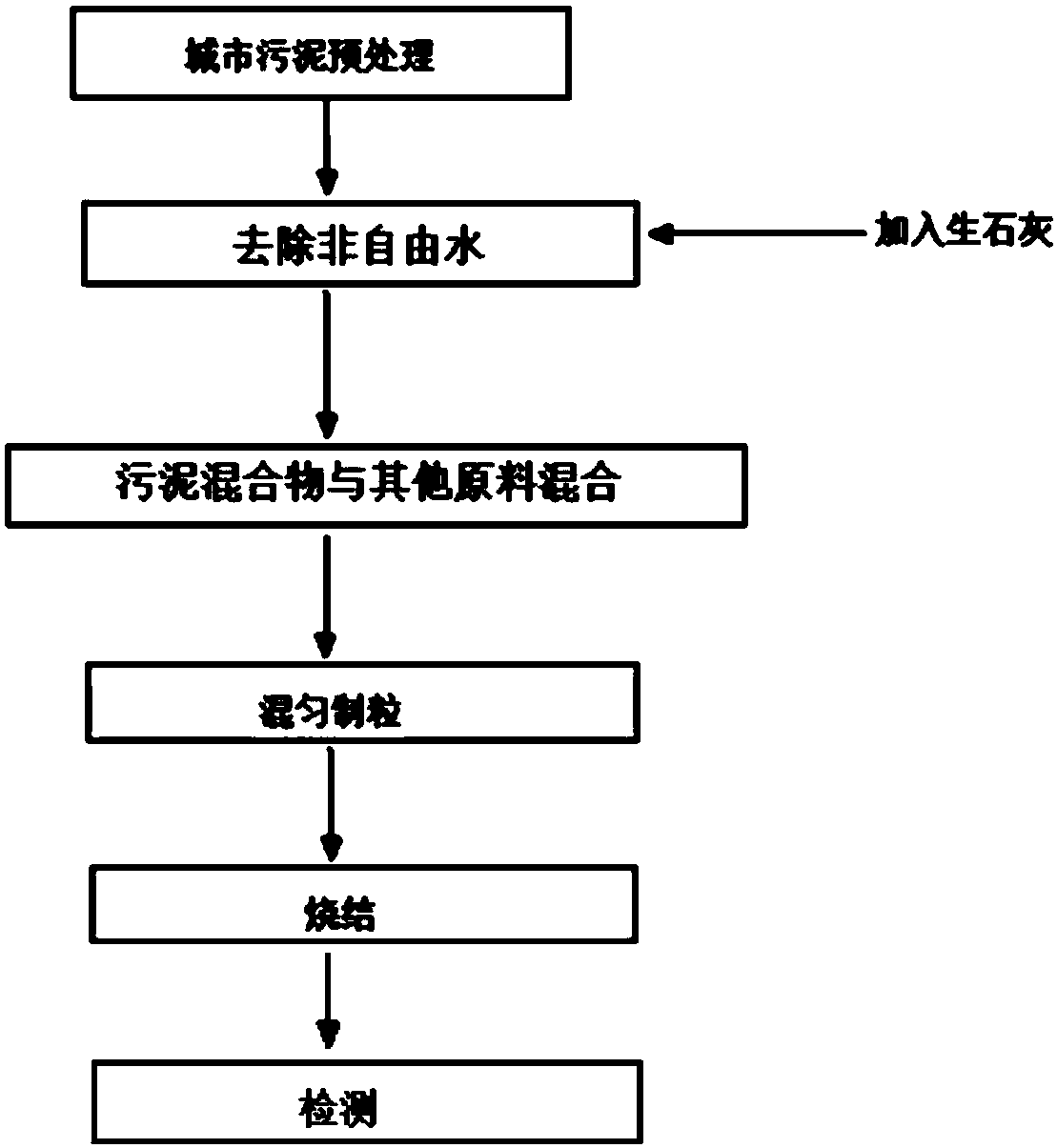

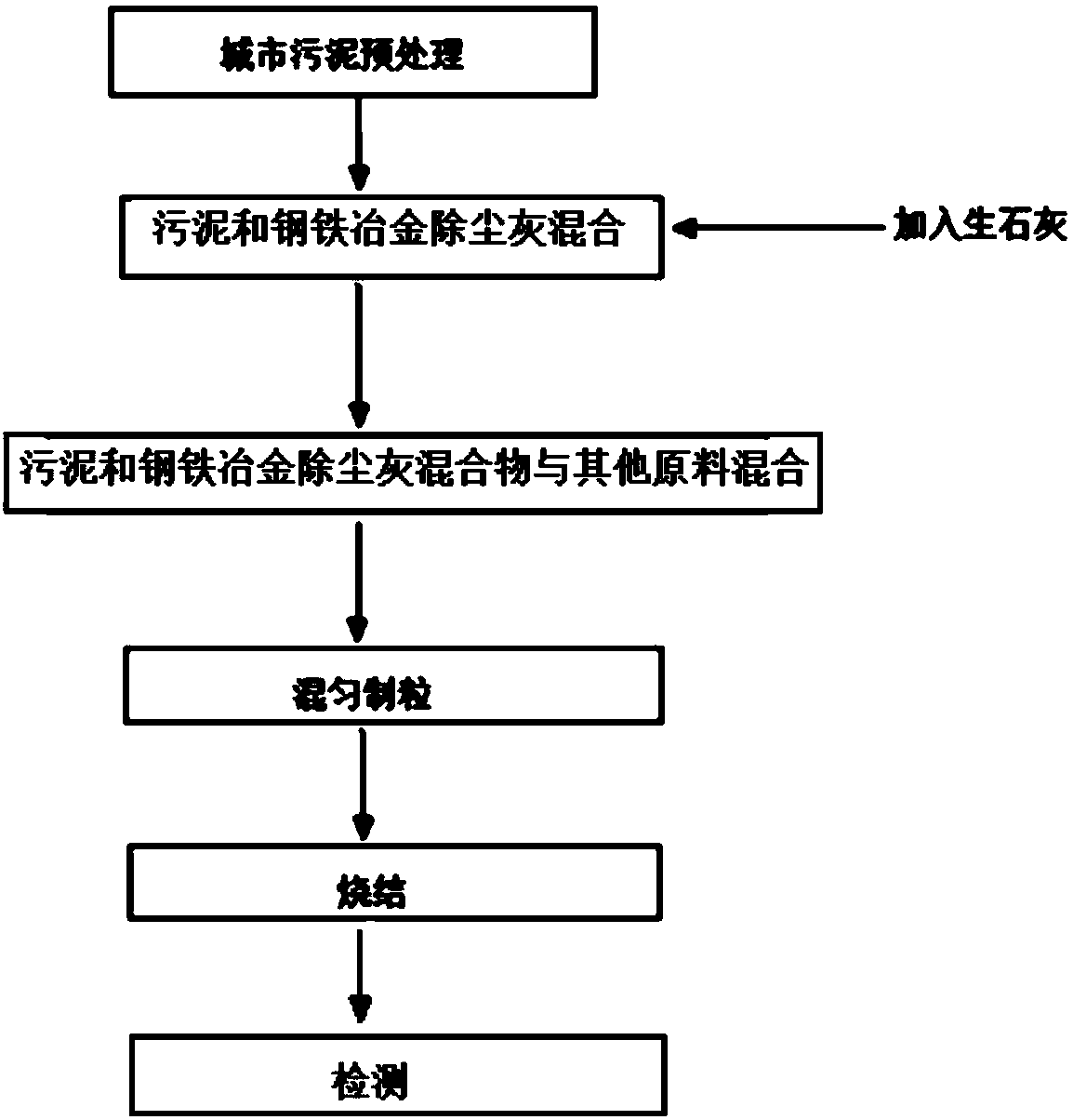

[0088] A method for treating sludge using a metallurgical sintering process, the method comprising the following steps:

[0089] (A) Sludge pretreatment step: dewatering the sludge produced by direct separation of urban sewage by pressure filtration to obtain dehydrated sludge with a water content of about 21wt%;

[0090] (B1) Step of removing non-free water: mixing and reacting quicklime and dehydrated sludge to obtain a sludge mixture, wherein the weight ratio of quicklime to dehydrated sludge is 1:2;

[0091] (C1) Dosing step: mix 10 parts by weight of the obtained sludge mixture with 190 parts by weight of sintering raw materials to obtain a sintering mixture; wherein the sintering raw materials include 67wt% iron ore fine powder for sintering, 26wt% Flux (1:1 weight ratio of dolomite and limestone), 7% anthracite powder, said weight ratio is based on the total weight of sintered raw materials; wherein: the amount of sludge mixture is 5wt%, and this weight percentage is ba...

Embodiment 2

[0097] Repeat embodiment 1, just replace the sludge that produces through the direct separation of urban sewage with the sludge that produces in the sewage treatment process; Add a small amount of water (that is, wet amount, i.e. 8wt%, based on the sintered mixture) in a mix total weight); in step (A), the sludge is dewatered by centrifugation.

Embodiment 3

[0099] Repeat embodiment 1, only the sludge that produces in the sludge directly separated from municipal sewage and the sludge produced in the sewage treatment process replaces the sludge produced directly through municipal sewage; In the step (B1), the weight of unslaked lime and the sludge after dehydration The ratio is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com