Magnesium alloy with LPSO and/or SFs structure and preparation method thereof

A magnesium alloy and alloy technology, applied in the field of magnesium alloy with LPSO and/or SFs structure and its preparation, can solve the problems of accelerated matrix corrosion, uneven corrosion of alloys, and no corrosion resistance performance, so as to improve corrosion resistance performance, uniform distribution, and the effect of reducing galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a magnesium alloy with LPSO and / or SFs structure, comprising the following steps in sequence:

[0051] (1) Material preparation and drying: Weigh talcum powder and sodium silicate, mix with water to make a coating, and then coat it on the inside of the casting mold and the inside of the melting crucible furnace;

[0052] Put the casting mold, pure magnesium ingot, Mg-30wt%Gd master alloy, Mg-30wt%Cu master alloy and Mg-30wt%Zr master alloy into a 200°C blast drying oven for standby; the weight of Gd and Cu is 100% content and not more than 9%;

[0053] Weigh the raw materials required for the refining agent and put them in a blast drying oven at 180 °C to keep them warm for later use;

[0054] Heat the melting furnace to 300-350 °C, and dry the crucible;

[0055] (2) Smelting: Put pure magnesium ingots in CO with a flow ratio of 90:7:3 2 , N 2 and SF 6 Melt in a smelting furnace with a ternary mixed protective gas, and the melting temperature...

Embodiment 2

[0064] Embodiment 2: Obtaining a solid solution state Mg-6.5Gd-2.5Cu-0.4Zr magnesium alloy finished product.

[0065] The solution treatment temperature was 290 °C, and the holding time was 12 hours.

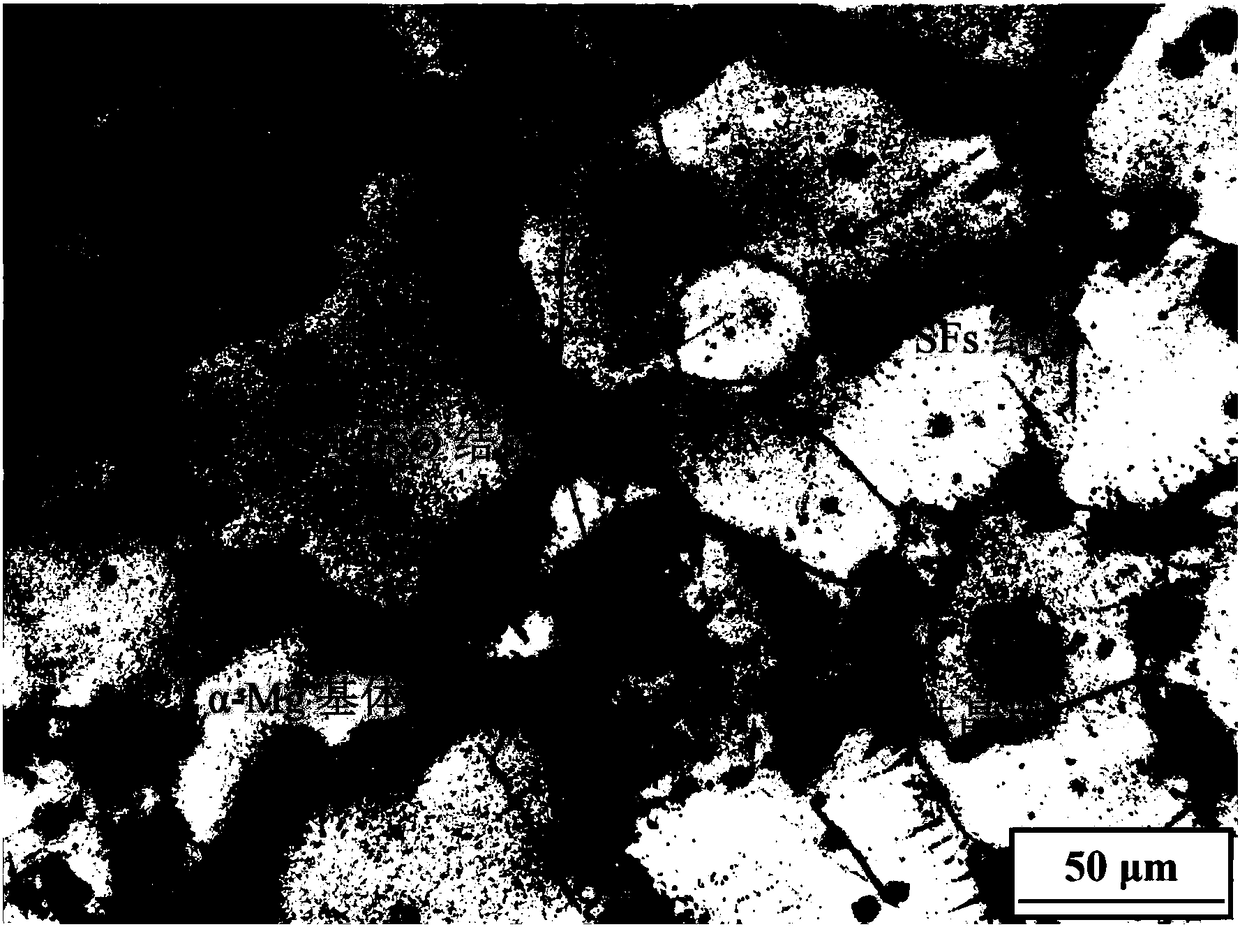

[0066] In addition to the α-Mg matrix, the structure in the alloy mainly includes eutectic phase, LPSO and SFs structure, and the content of eutectic phase at the grain boundary is less than that in Example 1, while the distribution of LPSO and SFs structure is not uniform, and its volume The score is comparable to that in Example 1, about 15%.

Embodiment 3

[0068] The solution treatment temperature was 320 °C, and the holding time was 6 hours.

[0069] In addition to the α-Mg matrix, the structure in the alloy mainly includes eutectic phase, LPSO and SFs structure, and the content of eutectic phase at the grain boundary is less than that in Example 1, while the distribution of LPSO and SFs structure is not uniform, and its volume Score is more than in embodiment one, is about 19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com