Ternary composite nano system based on methoxy polyethylene glycol-polylactic acid and application of ternary composite nano system

A technology of methoxy polyethylene glycol and polyethylene glycol, applied in the field of pharmaceutical preparations, can solve systemic toxicity, poor immediate release targeting, low drug loading and encapsulation efficiency, and inability to effectively encapsulate drugs and other problems to achieve the effect of increasing the efficacy of the drug, prolonging the circulation time in the body, and increasing the bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

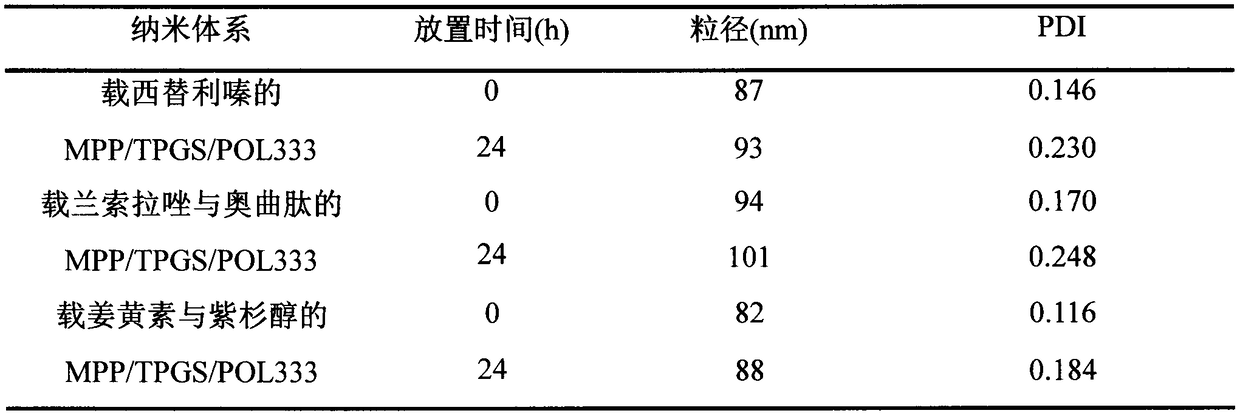

[0045] Embodiment 1: Preparation of MPP / TPGS / POL124 ternary composite nanosystem

[0046]Process I: Weigh an appropriate amount of MPP, TPGS, and POL124 and dissolve them in water respectively. The ratio of the total weight of MPP, TPGS, and POL124 to the weight of water is 3:1000, and the weight ratio of MPP, TPGS, and POL124 is 2:1:1, and stir for 1 hour , ultrasonication for 30min, dialysis for 24h, and 0.8μm microporous membrane filtration to obtain a ternary composite nanosystem based on MPP / TPGS / POL124.

[0047] Process II: Weigh an appropriate amount of MPP, TPGS, and POL124 and dissolve them in acetone, methanol, and methanol respectively. The weight ratio of MPP to acetone is 6:1000, the weight ratio of TPGS to methanol is 3:1000, and the weight ratio of POL124 to methanol is 3 : 1000, the weight ratio of MPP, TPGS and POL124 is 2:1:1, acetone and methanol are removed by rotary evaporation, vacuum dried for 12 hours after film formation, vigorously stirred with water ...

Embodiment 2

[0048] Example 2: Preparation of MPP / 4-arm-PEG-TPGS / POL185 ternary composite nanosystem loaded with indomethacin

[0049] Process I: Weigh an appropriate amount of MPP, 4-arm-PEG-TPGS, and POL185 and dissolve them in water respectively. The ratio of the total weight of MPP, 4-arm-PEG-TPGS, and POL185 to the weight of water is 30:1000. MPP, 4-arm -The weight ratio of PEG-TPGS to POL185 is 5:2:1. Weigh an appropriate amount of indomethacin and dissolve it in ethanol. The weight ratio of indomethacin to ethanol is 15:1000. Indomethacin and MPP / 4- The weight ratio of arm-PEG-TPGS / POL185 is 3:20, slowly add the indomethacin solution dropwise into the MPP / 4-arm-PEG-TPGS / POL185 solution, stir at room temperature for 2h, ultrasonic for 30min, dialyze for 24h, 0.8 The MPP / 4-arm-PEG-TPGS / POL185 ternary composite nanosystem loaded with indomethacin was obtained by filtering with a microporous membrane of μm.

[0050] Process II: Weigh an appropriate amount of MPP, 4-arm-PEG-TPGS, and PO...

Embodiment 3

[0051] Example 3: Preparation of MPP / TLA / POL238 ternary composite nanosystem loaded with lansoprazole and octreotide

[0052] Process I: Weigh an appropriate amount of MPP, TLA, and POL238 and dissolve them in water respectively. The ratio of the total weight of MPP, TLA, and POL238 to the weight of water is 50:1000, and the weight ratio of MPP, TLA, and POL238 is 10:3:4. A suitable amount of lansoprazole is dissolved in dimethylformamide, and an appropriate amount of octreotide is taken and dissolved in water. The weight ratio of lansoprazole and dimethylformamide is 20: 1000, and the weight ratio of octreotide and water is 15: 1000. The weight ratio of lansoprazole and octreotide is 1: 1, and the weight ratio of the total weight of lansoprazole and octreotide to MPP / TLA / POL238 is 1: 3, and the solution of lansoprazole and octreotide is slowly added dropwise to MPP / TLA / POL238 solution, stirred at room temperature for 2 hours, ultrasonicated for 40 minutes, dialyzed for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com