Coenzyme Q10, octacosanol and cyclodextrin multi-element supermolecule clathrate compound and preparation method thereof

A technology of octacosanol and cyclodextrin, which is applied in the fields of medicine and health care products to achieve the effect of excellent antioxidant properties and the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

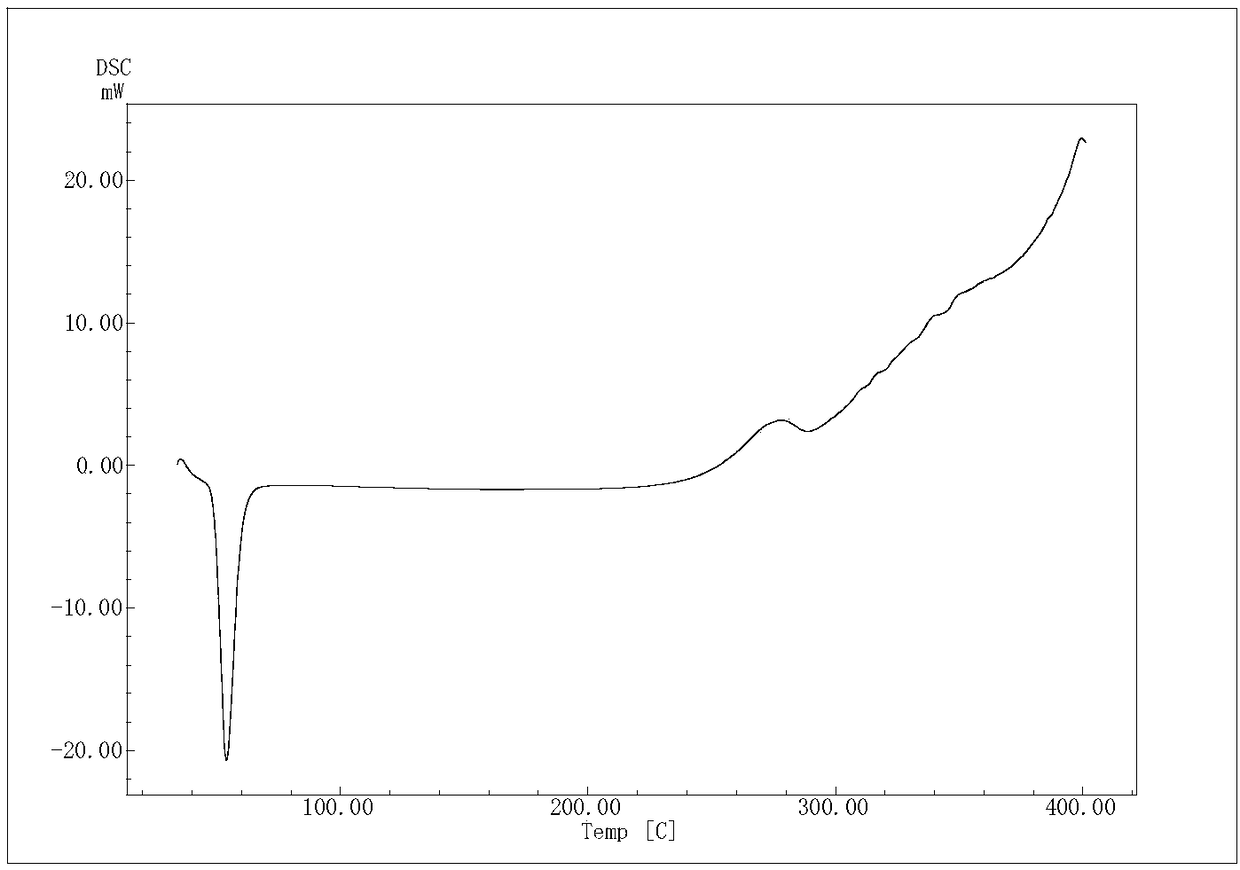

Embodiment 1

[0053] Oxidized coenzyme Q of the present invention 10 The ternary supramolecular clathrate with octacosanol cyclodextrin is prepared as follows: take 30 parts by weight of β-cyclodextrin, add 150 parts by weight of water and mix, heat to 60°C, and then add 10 parts by weight of oxidation Coenzyme Q 10 and 1 part by weight of octacosanol, stirred into a paste, put into a colloid mill, circulated and ground 15 times, discharged, added water until the solid content reached 12%, and spray-dried to obtain oxidized coenzyme Q 10 Cyclodextrin ternary supramolecular inclusion compound compounded with octacosanol. Determination of coenzyme Q in clathrate by HPLC and gas chromatography respectively 10 and encapsulation efficiency of octacosanol, coenzyme Q 10 The encapsulation rate was 69.2%, and the encapsulation rate of octacosanol was 65.3%.

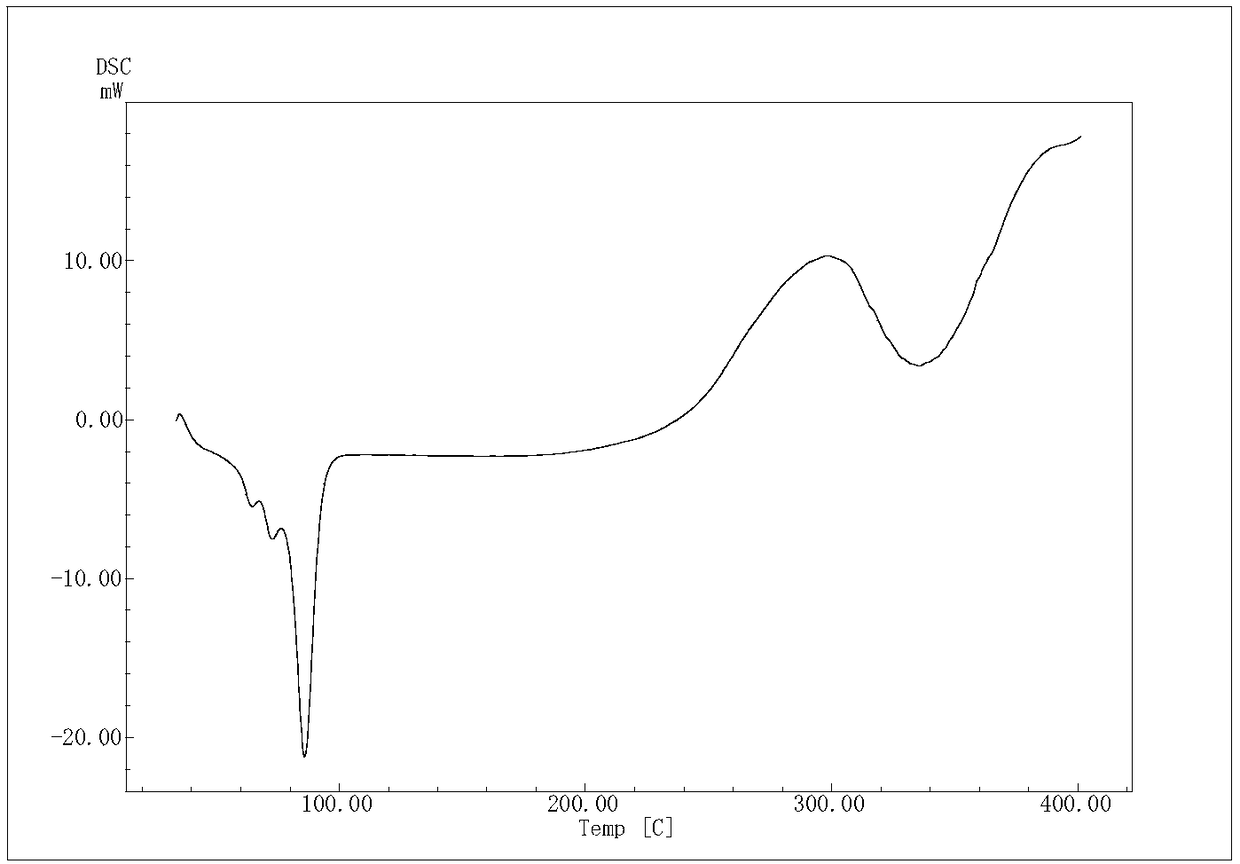

Embodiment 2

[0055] Reduced coenzyme Q of the present invention 10 The ternary supramolecular inclusion compound with octacosanol cyclodextrin is prepared as follows: Take 50 parts by weight of β‐cyclodextrin, add 250 parts by weight of water, mix, heat to 65°C, and then add 10 parts by weight Reduced coenzyme Q 10 and 2 parts by weight of octacosanol, stirred into a paste, put into a colloid mill, circulated and ground 20 times, discharged, added water until the solid content reached 13%, and freeze-dried to obtain reduced coenzyme Q 10 Cyclodextrin ternary supramolecular inclusion compound compounded with octacosanol. Determination of coenzyme Q in clathrate by HPLC and gas chromatography respectively 10 and encapsulation efficiency of octacosanol, coenzyme Q 10 The encapsulation rate was 89.1%, the encapsulation rate of octacosanol was 85.3%, and the calculated encapsulation ratio was 1:0.33:6.06.

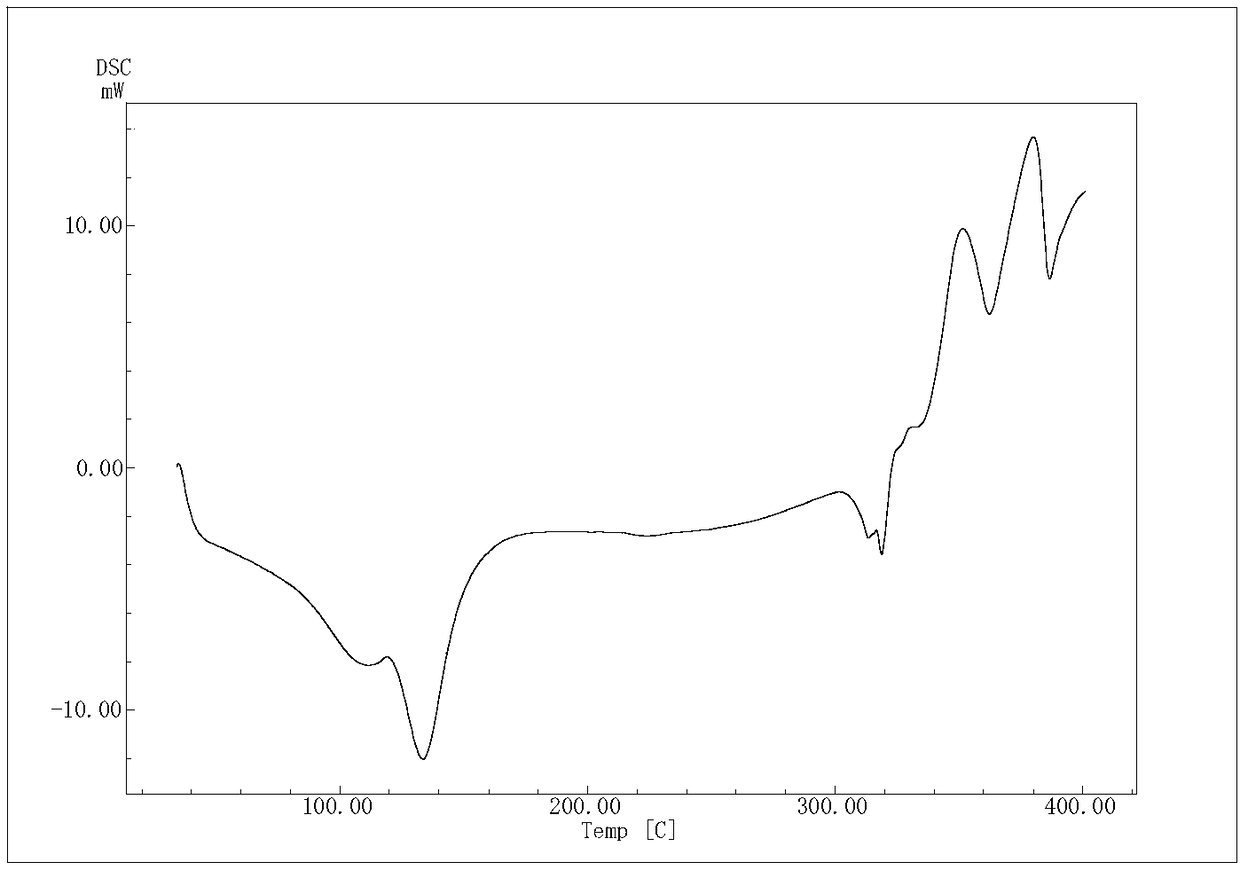

Embodiment 3

[0057] Oxidized coenzyme Q of the present invention 10 The preparation method of the ternary supramolecular inclusion complex with octacosanol cyclodextrin is as follows: take 100 parts by weight of β-cyclodextrin, add 400 parts by weight of water and mix, heat to 90°C, and then add 10 parts by weight of oxidized coenzyme Q 10 and 5 parts by weight of a mixture of 50% octacosanol C22 to C36 higher fatty alkanol, stirred into a paste, put into a colloid mill, and circulated for 20 times of grinding, discharging, adding water until the solid content reaches 11%, Carry out spray drying, obtain oxidized coenzyme Q 10 Cyclodextrin ternary supramolecular inclusion compound compounded with octacosanol. Determination of coenzyme Q in clathrate by HPLC and gas chromatography respectively 10 and encapsulation efficiency of octacosanol, coenzyme Q 10 The encapsulation rate was 85.3%, and the encapsulation rate of octacosanol was 81.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com