Blocking film with low heat bridge effect and vacuum heat insulation plate with blocking film

A technology of barrier film and barrier film, which is applied in the direction of coating, layered products, synthetic resin layered products, etc. It can solve the problems of low mechanical strength, easy transfer of aluminum plating, and affect the service life of vacuum insulation products, etc., to improve Thermal insulation performance, improve surface compactness, and avoid thermal bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

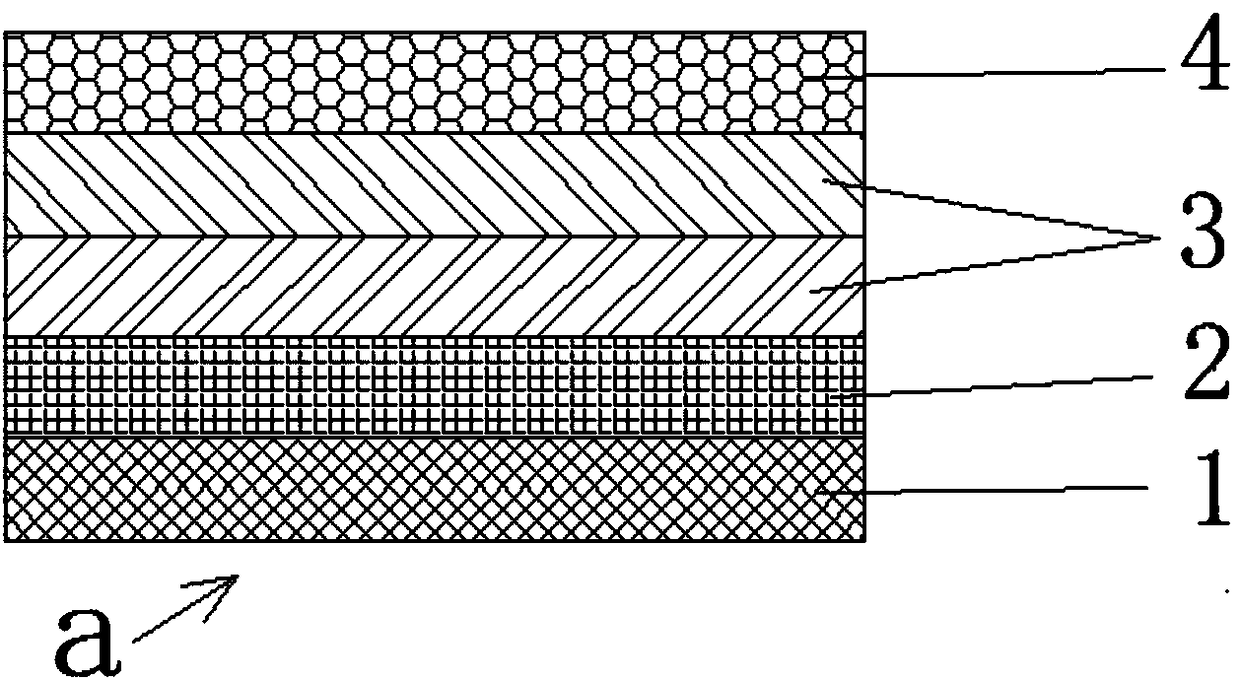

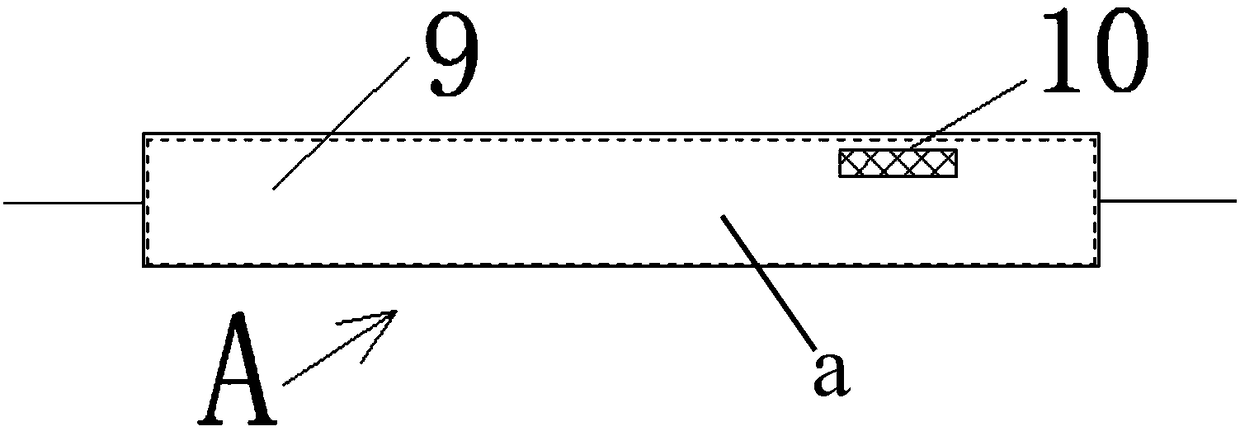

[0027] refer to figure 1 , a low thermal bridge effect barrier film made of Al-plated 2 o 3 A PET layer 1, a nylon layer 2, two layers of nano-barrier film layers 3, and a PE layer 4 are sequentially bonded by an adhesive.

[0028] The Al plating 2 o 3 PET layer 1 is the outermost waterproof layer, its oxygen permeability (23°C, 50% RH) ≤ 1cc / ㎡.day, water permeability (38°C, 90% RH) ≤ 1g / ㎡.day, has excellent Moisture barrier performance, and good chemical stability, has excellent cooking resistance, as the first line of barrier defense of the barrier film, at the same time, it plays a further protective role for the nano-barrier film layer 3 in the middle, so that the barrier film It can also maintain good barrier properties under high temperature and high humidity conditions.

[0029] In the Al-plated 2 o 3 Al plating of PET layer 1 2 o 3 The nylon layer 2 is compounded with an adhesive. The nylon layer 2 has good wear resistance and weather resistance, and plays a r...

Embodiment 2

[0038] refer to Figure 4 and Figure 5 , the difference between this embodiment and embodiment 1 is: a low thermal bridge effect barrier film, composed of F-containing modified PET layer 1', nylon layer 2, two layers of nano-barrier film layer 3', PE layer 4 through an adhesive Glue the composition in sequence.

[0039] The water permeability of 12μm PET (38°C, 90% RH) is about 30g / ㎡.day. If the PET is coated with fluorine-containing glue, the water permeability can be reduced to about 1g / ㎡.day. The F-containing modified PET layer 1' is used as the outermost waterproof layer, which reduces the overall water permeability of the composite membrane and at the same time ensures the service life of the barrier membrane in a humid environment. The thickness of the F-containing modified PET layer 1' is 10-20 μm.

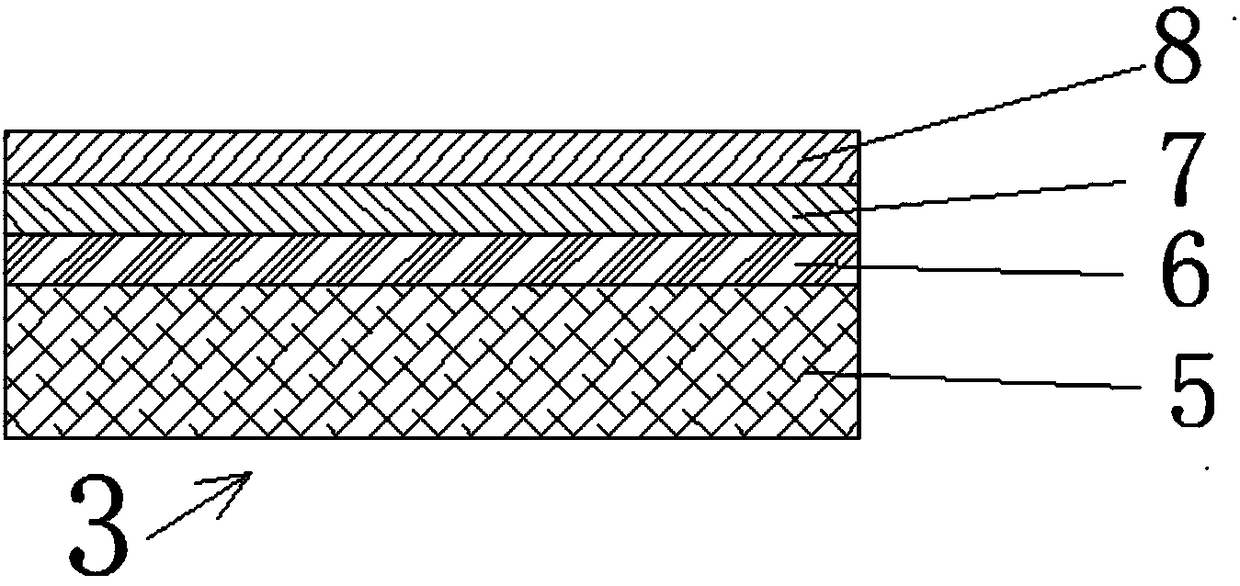

[0040] The nano-barrier film layer 3' is successively an aluminum-plated base film 5, an undercoat layer 6, a barrier coating 7', and an aluminum-plated layer 8 from bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com