Method for preparing small-size cellulose nanocrystal

A cellulose and nanocrystal technology, which is applied in the field of preparation of small-sized cellulose nanocrystals, can solve the problems that the particle size of cellulose nanocrystals is not seen, the cellulose nanocrystals cannot meet the particle size requirements of cellulose nanocrystals, and the like, Achieve the effect of high yield, easy operation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

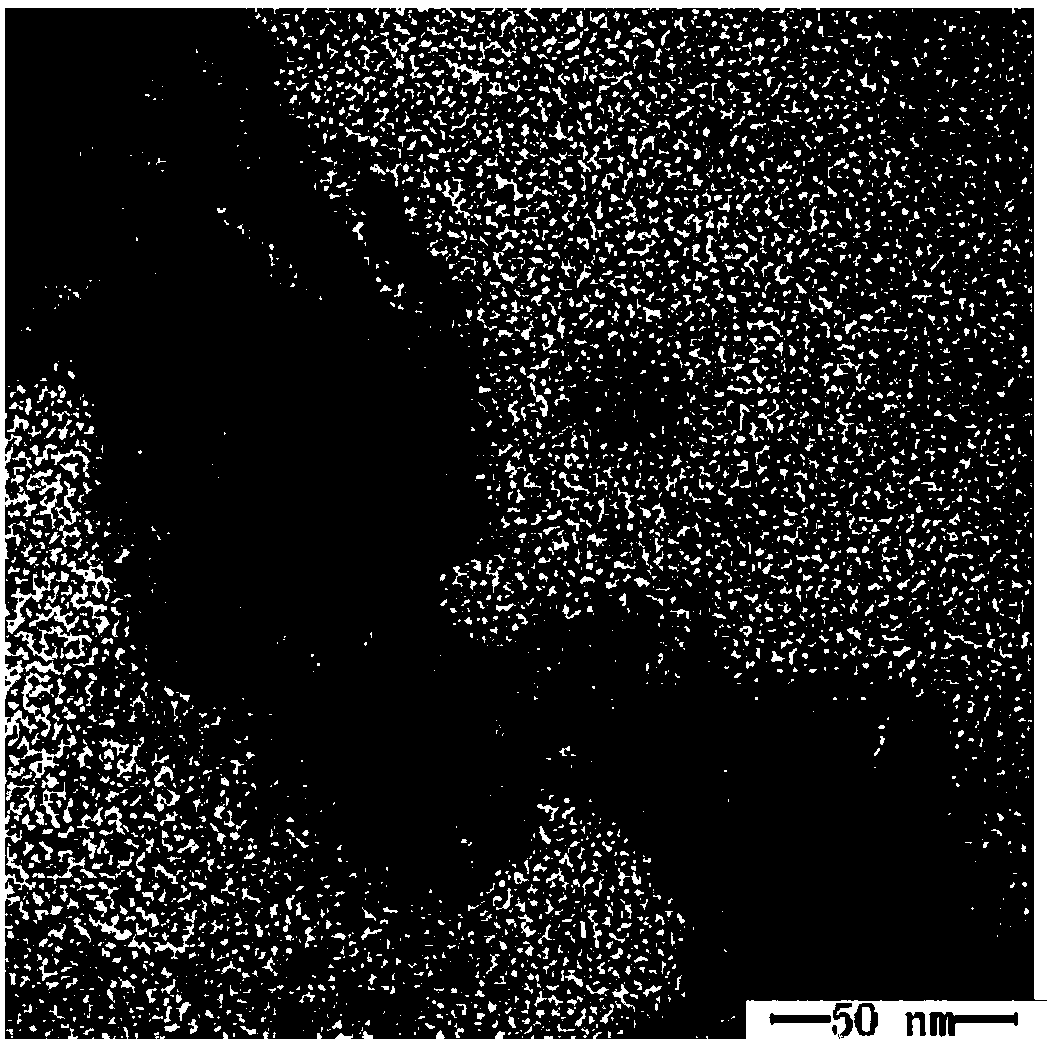

Embodiment 1

[0021] Cut 4.6g of cotton into rods with a length and diameter of about 5-7nm and 1.5-2nm, add it to 200mL of sulfuric acid solution with a concentration of 64%, and react for 40min at a temperature of 45°C. dilution. Take the upper suspension and centrifuge at 10,000rpm for 20min at 10°C to obtain a white solid. Ultrasonically disperse the white solid in 40mL of water, and centrifuge under the above conditions (repeat the operation 3 times). Finally, the white solid is dispersed in 40mL of water. Dialysis treatment (molecular weight cut-off Da: MW: 3500), the sample after dialysis treatment was freeze-dried to obtain larger size cellulose nanocrystals. Weigh 0.25g of larger sized cellulose nanocrystals and dissolve in 10mL of DMSO, add 0.5g of sodium tert-butoxide and dissolve in 10mL of DMSO solution at a temperature of 45°C, react for 72h, and the obtained product is dispersed in 150mL at a temperature of 10°C The dispersion was centrifuged at 10000 rpm for 20 min at 10°C,...

Embodiment 2

[0023] The type of raw materials used, the amount and the process flow are the same as those in Example 1, except that the DMSO solution containing 0.25 g of larger-sized cellulose nanocrystals is added, and 0.5 g of potassium tert-butoxide is dissolved in 10 mL of DMSO, with a yield of 79% %. The measured average size of the obtained cellulose nanocrystals is less than 50nm.

Embodiment 3

[0025] The type of raw materials used, the amount and the process flow are the same as those in Example 1, except that the DMSO solution containing 0.3 g of larger-sized cellulose nanocrystals is added, and 0.6 g of lithium tert-butoxide is dissolved in 10 mL of DMSO, with a yield of 81 %. The measured average size of the obtained cellulose nanocrystals is less than 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com