Nano barrier film and preparation method thereof

A barrier film, nano-technology, applied in the field of nano-barrier film and its preparation, can solve the problems of water and gas barrier performance decline, boundary heat leakage increase, poor durability, etc., to achieve water and gas barrier performance improvement, edge thermal bridge effect Weak, effect of improving surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

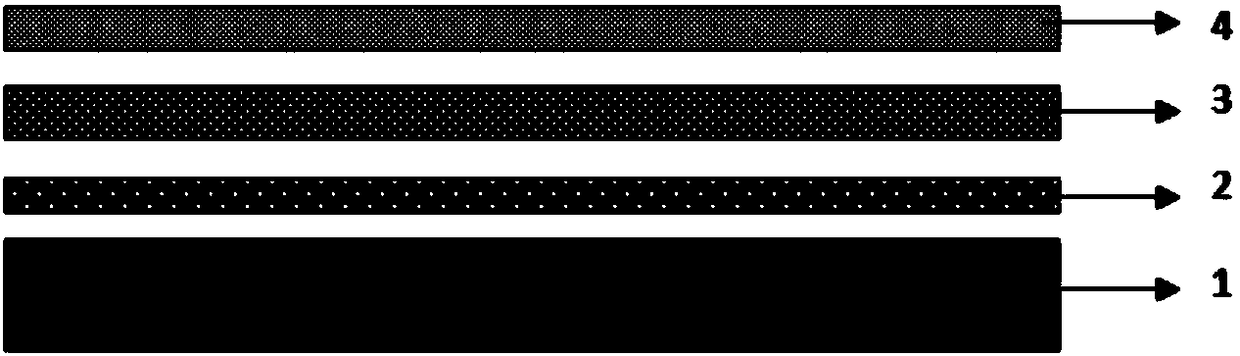

[0029] refer to figure 1 , a nano-barrier film, from bottom to top is an aluminum-plated base film 1, an undercoat 2, a barrier coating 3, and a nano-coating 4.

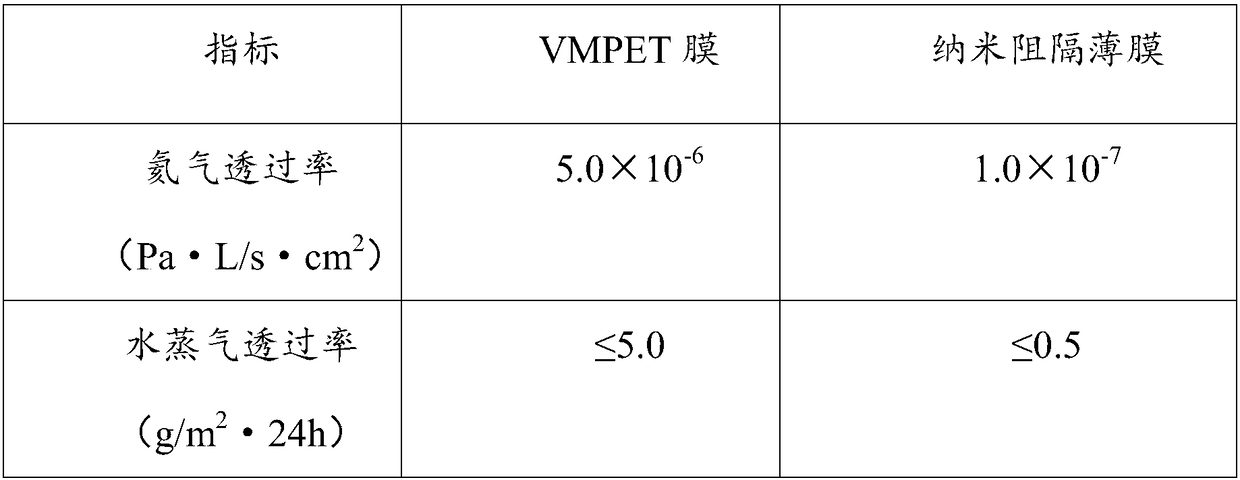

[0030] The aluminized base film 1 is preferably an aluminized polyethylene terephthalate film (VMPET) with a thickness of 12 μm, and may also be a 25 μm aluminized cast polypropylene film (VMCPP) or a 20 μm biaxially oriented polypropylene film. One of the films (VMBOPP). The aluminum-coated base film 1 is not limited to the above-mentioned three types. A suitable plastic base material can be vapor-deposited with metal, has a low thermal conductivity, and has a certain water- and gas-blocking ability. The aluminized base film 1 is already a very mature film with a certain ability to block water and gas, and it appears as the structure with the main barrier ability in the traditional composite film layer of the outer packaging material in the field of vacuum insulation panels. However, films such as the aluminized b...

Embodiment 2

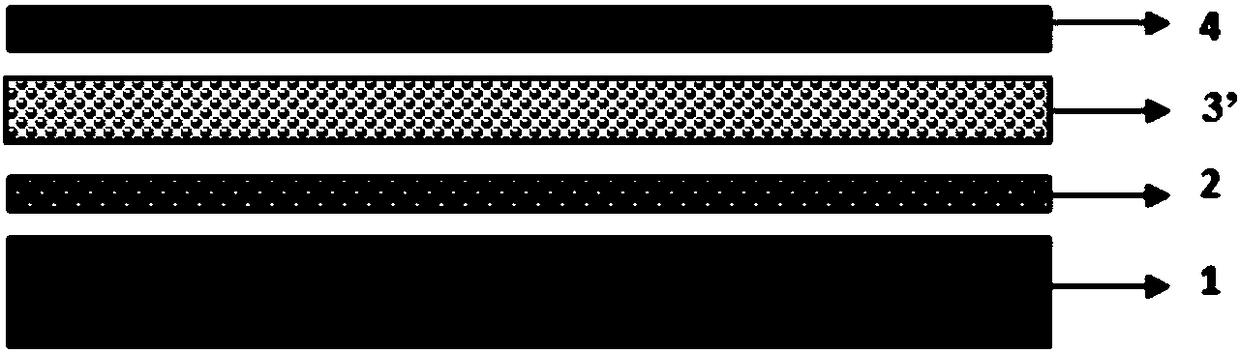

[0039] refer to figure 2 , the difference between this embodiment and embodiment 1 is: the barrier coating 3' also includes inorganic nanoparticles with a specific gravity of 5-9%, and the inorganic nanoparticles are silicon oxide nanoparticles with a particle size of 10~50nm. Due to the fluidity and surface tension of the barrier coating 3' coating liquid, after drying, the microscopic state of the coating surface is not smooth and flat, and the nano particles are dispersed and filled on the surface of the coating film to reduce its roughness and improve the coating during vacuum evaporation. of adhesion.

[0040] This embodiment further provides the preparation method of the above-mentioned nano-barrier film, including the following steps:

[0041] 1) Coating a layer of base coat 2 paint on the aluminum-plated surface of the aluminum-plated base film 1, the coating amount is 0.5-1.0g / m2, and drying.

[0042] The aluminized base film 1 is preferably an aluminized polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com