Special PPS (polyphenylene sulfide) plastic having good bonding property with epoxy adhesive and preparation method of PPS plastic

An epoxy glue and special technology, applied in the field of special plastics, can solve the problems that PPS resin cannot be bonded with epoxy glue, cannot meet the strong bonding force, insufficient insulation and sealing performance, etc., so as to meet the requirements of the glue filling process and improve the mechanical properties. and heat resistance, the effect of improving polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

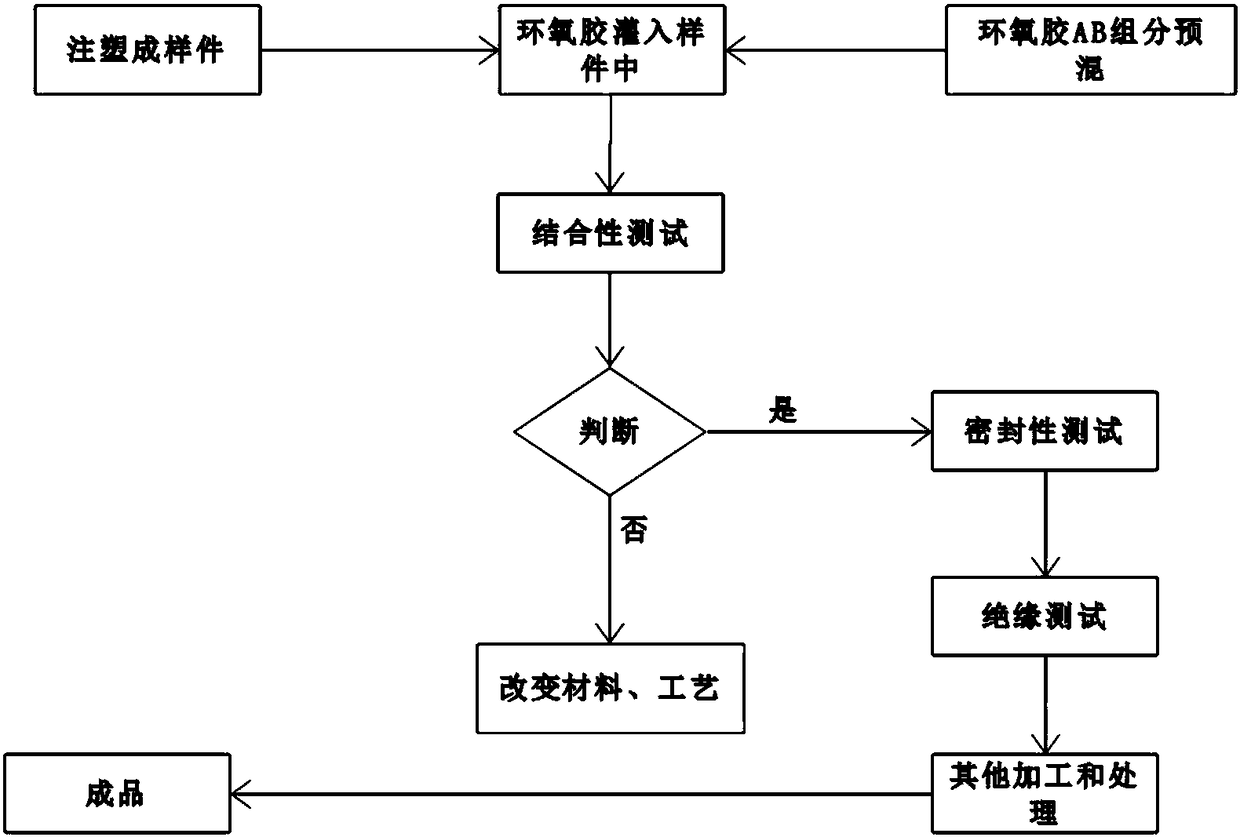

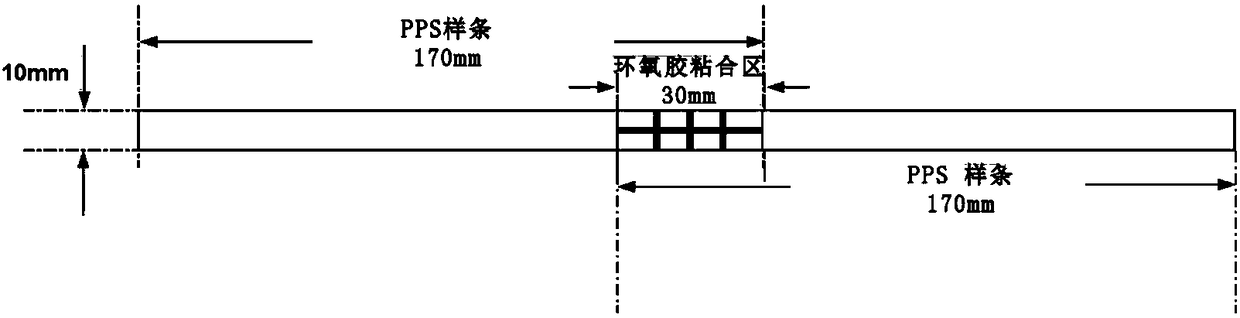

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the PPS special plastics that is used for glue-filling technology and good epoxy resin combination of the present embodiment, by mass parts, comprises the following components:

[0055] 50 parts of PPS resin, 3 parts of toughening agent, 0.3 parts of antioxidant, 0.3 parts of heat stabilizer, 2 parts of silane coupling agent, 1 part of colorant, 45 parts of glass fiber.

[0056] Wherein, the toughening agent is styrene thermoplastic elastomer, and the antioxidant is polybasic hindered phenol and phosphite.

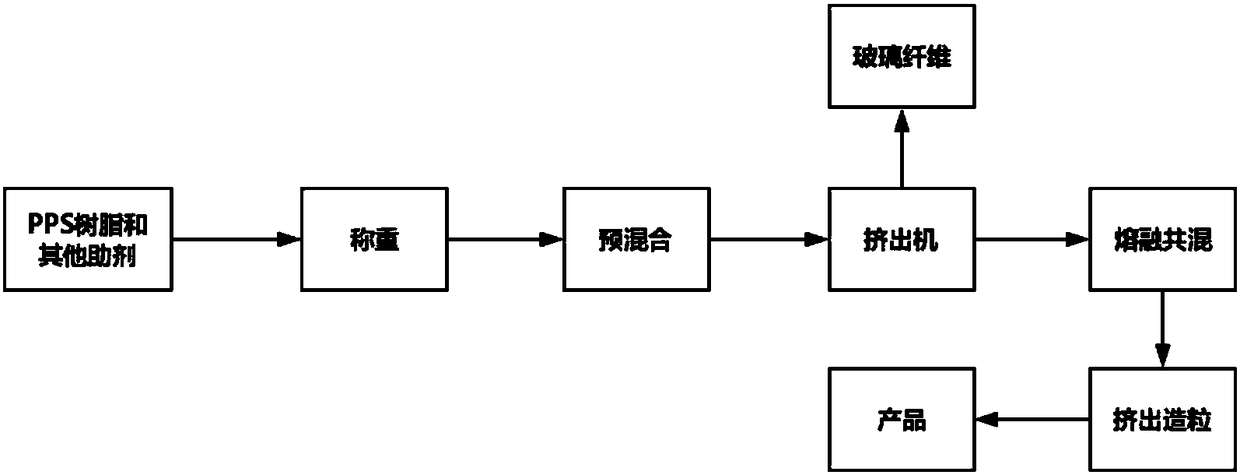

[0057] The preparation method of the above-mentioned PPS special plastic with good bonding with epoxy resin is as follows:

[0058] In terms of parts by mass, 50 parts of PPS resin, 3 parts of toughening agent, 0.3 part of antioxidant, 0.3 part of heat stabilizer, 2 parts of silane coupling agent and 1 part of colorant are pre-mixed to obtain a mixture, and the mixture And 45 parts of glass fibers are put into the extruder, melt blending and extrusion...

Embodiment 2

[0060] Embodiment 2: the PPS special plastics that is used for glue-filling technology and good epoxy resin binding property of the present embodiment, by mass parts, comprises the following components:

[0061] 50 parts of PPS resin, 3 parts of toughening agent, 0.3 parts of antioxidant, 0.3 parts of heat stabilizer, 2 parts of silane coupling agent, 1 part of colorant, 45 parts of glass fiber.

[0062] Wherein, the toughening agent is styrene thermoplastic elastomer and GMA, and the GMA is 20% of the total mass of the toughening agent, and the antioxidant is multi-component hindered phenol and phosphite.

[0063] The preparation method of the PPS special plastic with good epoxy resin bonding properties used in the glue filling technology in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0064] Embodiment 3: the PPS special plastics that is used for glue-filling technology and good epoxy resin combination of the present embodiment, by mass parts, comprises the following components:

[0065] 50 parts of PPS resin, 3 parts of toughening agent, 0.3 parts of antioxidant, 0.3 parts of heat stabilizer, 2 parts of silane coupling agent, 1 part of colorant, 45 parts of glass fiber.

[0066] Wherein, the toughening agent is styrene thermoplastic elastomer and GMA, the GMA is 50% of the total mass of the toughening agent, and the antioxidant is multi-component hindered phenol and phosphite.

[0067] The preparation method of the PPS special plastic used in the glue pouring technology in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com