Biomass polyacid modified polyester resin and preparation method thereof

A technology of modifying polyester and polyacid, applied in polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of small molecular weight and simple structure, improve acid and alkali resistance and water resistance, and improve impact strength and toughness, good aging resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

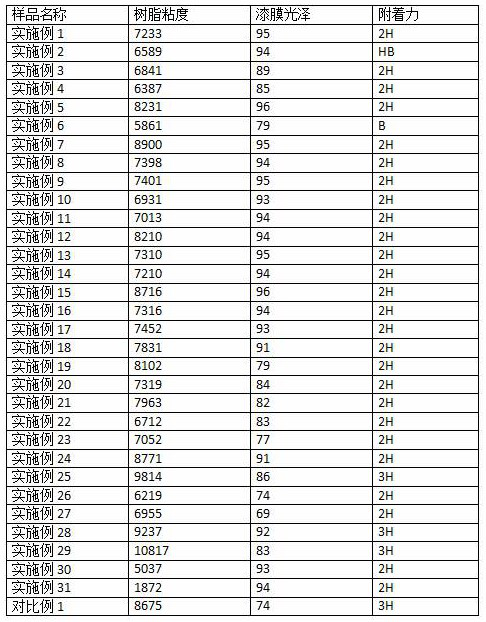

Examples

Embodiment 1

[0020] In the present embodiment, prepare materials: get 100 parts by weight of oleic acid dimer acid monomer, 10 parts by weight of ethylene glycol monomer, an appropriate amount of dibutyltin dilaurate and 100 parts by weight of xylene solvent, a pH regulator and an appropriate amount of cooling water, Synthesized as follows:

[0021] 1) The reaction kettle is ventilated with nitrogen and preheated;

[0022] 2) Add alcohol monomer, acid monomer, solvent and catalyst in sequence, raise the temperature to 120 degrees, and keep it warm for 1 hour;

[0023] 3) Heat up to 230 degrees again, keep warm until the solution is transparent;

[0024] 4) Add a pH regulator to neutralize the remaining acid, cool down and add water, cool and discharge.

Embodiment 2

[0026] The difference between the biomass polyacid-modified polyester resin in this example and Example 1 is that in this example, oleic acid dimer acid is replaced with oleic acid trimer acid.

Embodiment 3

[0028] The difference between the biomass polyacid-modified polyester resin in this example and that in Example 1 is that in this example, the polyol monomer ethylene glycol is replaced with propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com