Self-supporting lithium-sulfur battery cathode material, preparation method and application thereof

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve problems such as irreversible loss of active materials and capacity fading, damage to the structural stability of positive electrode materials, and affect battery stability. Shuttle effect, green and environmentally friendly technology, and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

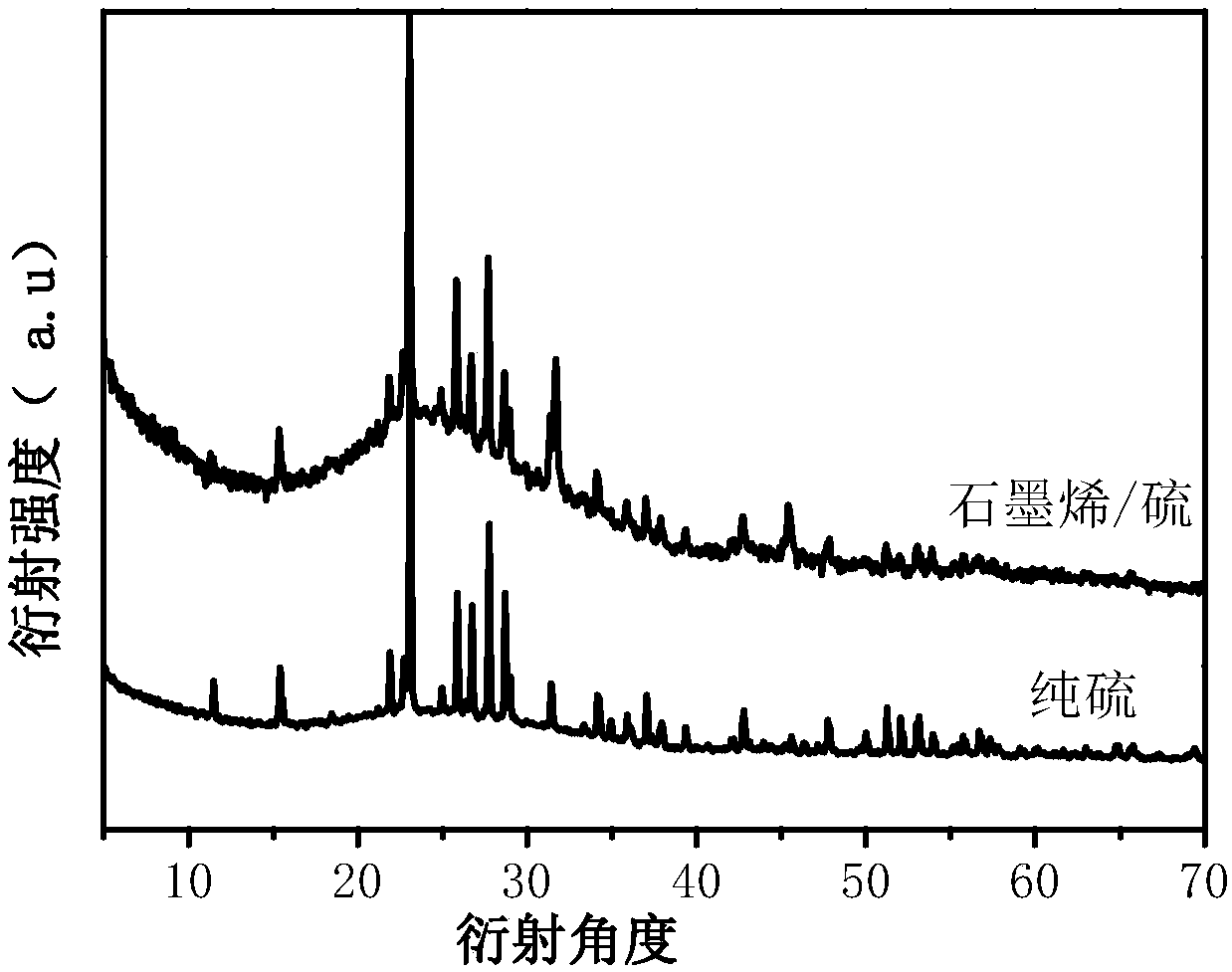

[0030] A self-supporting lithium-sulfur battery positive electrode material, the positive electrode material is graphene / sulfur sponge, the graphene / sulfur sponge has a rich porous structure similar to the sponge structure, the graphene / sulfur sponge is composed of graphene and The graphene sponge is composed of entangled sulfur particles.

[0031] A method for preparing a positive electrode material for a self-supporting lithium-sulfur battery, specifically comprising the following steps:

[0032] S100. Weigh 30 mg of graphene oxide and disperse it into 10 ml of deionized water, disperse evenly by ultrasonication for 1 hour, then add 120 mg of sodium thiosulfate pentahydrate, disperse evenly by ultrasonication, and obtain a mixed solution A;

[0033] S200. Under vigorous stirring, the mixed solution A is slowly dripped into dilute hydrochloric acid drop by drop with a syringe, and the dropping rate is controlled at 2 seconds per drop, until the pH value is 6.5-7, stop the dri...

Embodiment 2

[0040] A self-supporting lithium-sulfur battery positive electrode material, the positive electrode material is graphene / sulfur sponge, the graphene / sulfur sponge has a rich porous structure similar to the sponge structure, the graphene / sulfur sponge is composed of graphene and The graphene sponge is composed of entangled sulfur particles.

[0041] A method for preparing a positive electrode material for a self-supporting lithium-sulfur battery, specifically comprising the following steps:

[0042] S100. Weigh 30 mg of graphene oxide and disperse it into 10 ml of deionized water, disperse evenly by ultrasonication for 1 hour, then add 140 mg of sodium thiosulfate pentahydrate, disperse evenly by ultrasonication, and obtain a mixed solution A;

[0043] S200. Under vigorous stirring, the mixed solution A is slowly dripped into dilute hydrochloric acid drop by drop with a syringe, and the dropping rate is controlled at 2 seconds per drop, until the pH value is 6.5-7, stop the dri...

Embodiment 3

[0050] A self-supporting lithium-sulfur battery positive electrode material, the positive electrode material is graphene / sulfur sponge, the graphene / sulfur sponge has a rich porous structure similar to the sponge structure, the graphene / sulfur sponge is composed of graphene and The graphene sponge is composed of entangled sulfur particles.

[0051] A method for preparing a positive electrode material for a self-supporting lithium-sulfur battery, specifically comprising the following steps:

[0052] S100. Weigh 40 mg of graphene oxide and disperse it into 10 ml of deionized water, disperse evenly by ultrasonication for 1 hour, then add 120 mg of sodium thiosulfate pentahydrate, disperse evenly by ultrasonication, and obtain a mixed solution A;

[0053] S200. Under vigorous stirring, the mixed solution A is slowly dripped with dilute hydrochloric acid drop by drop with a syringe, and the dropping rate is controlled at 2 seconds per drop, until the pH value is 6.5-7, stop the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com