Preparation method of sandwich type photoresist sacrificial layer

A photoresist, sandwich-type technology, applied in coating, manufacturing microstructure devices, metal material coating process, etc., can solve the problems of difficult to achieve high-precision pattern preparation, high equipment requirements, difficult step structure, etc. The effect of low dependence, low heat treatment temperature, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment and attached Figure 1-6 The present invention is further explained.

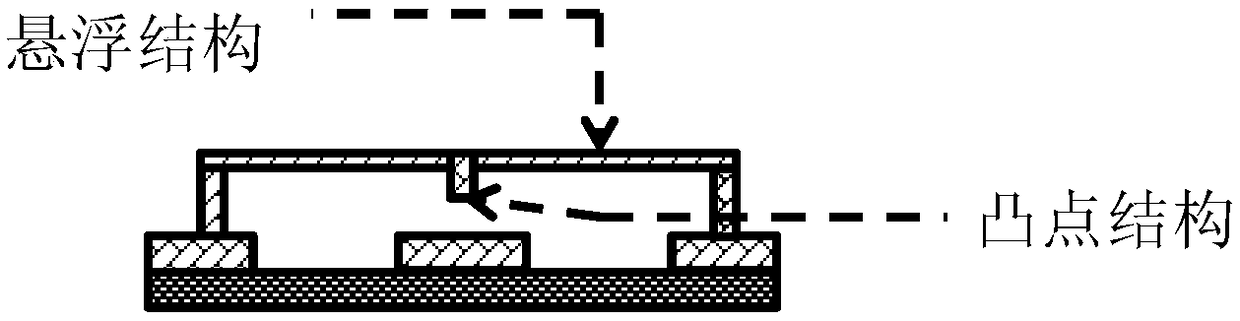

[0030] figure 1 It is a schematic diagram of a RFMEMS switch with contacts, including the lower circuit structure and the suspension structure, and there is a bump structure in the suspension structure; to form such figure 1 Suspension structure shown in, the present invention has designed a kind of preparation method of sandwich type photoresist sacrificial layer, comprises the following steps:

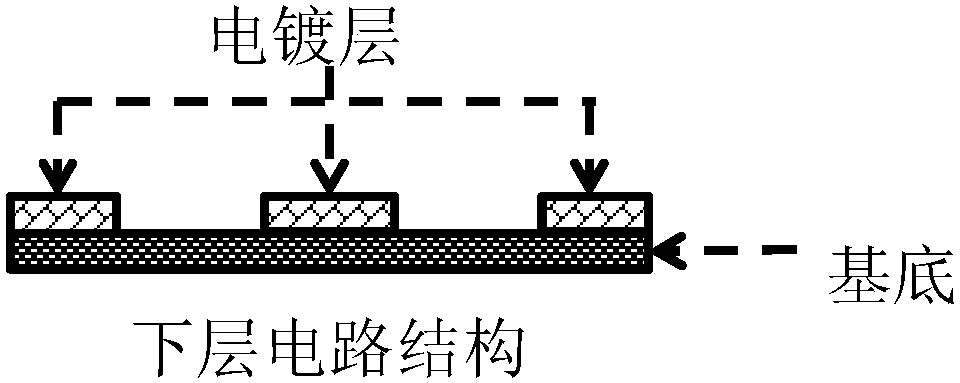

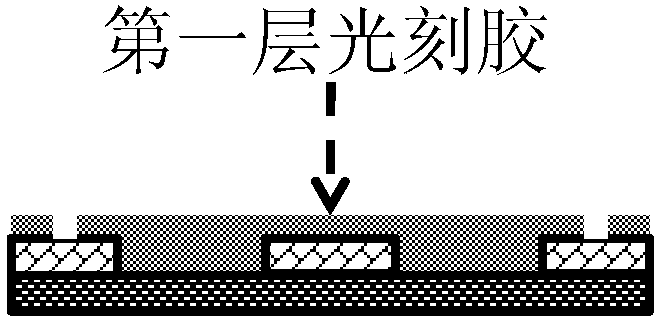

[0031] 1. Preparation of lower positive glue: figure 2 It is a schematic diagram of the lower circuit before making the sacrificial layer. The lower circuit structure includes the substrate and the circuit structure processed by electroplating; the first layer of positive resist is spin-coated on the lower circuit, and the patterning is completed by exposure and development. After patterning, the photoresist of this layer is heat-treated to form such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com