Method for treating lithium-containing waste residues

A treatment method and waste slag technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of unsafe treatment of metal lithium waste slag, out-of-control combustion, complicated process, etc., and achieve safety and easy recycling and treatment The effect of less time-consuming and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

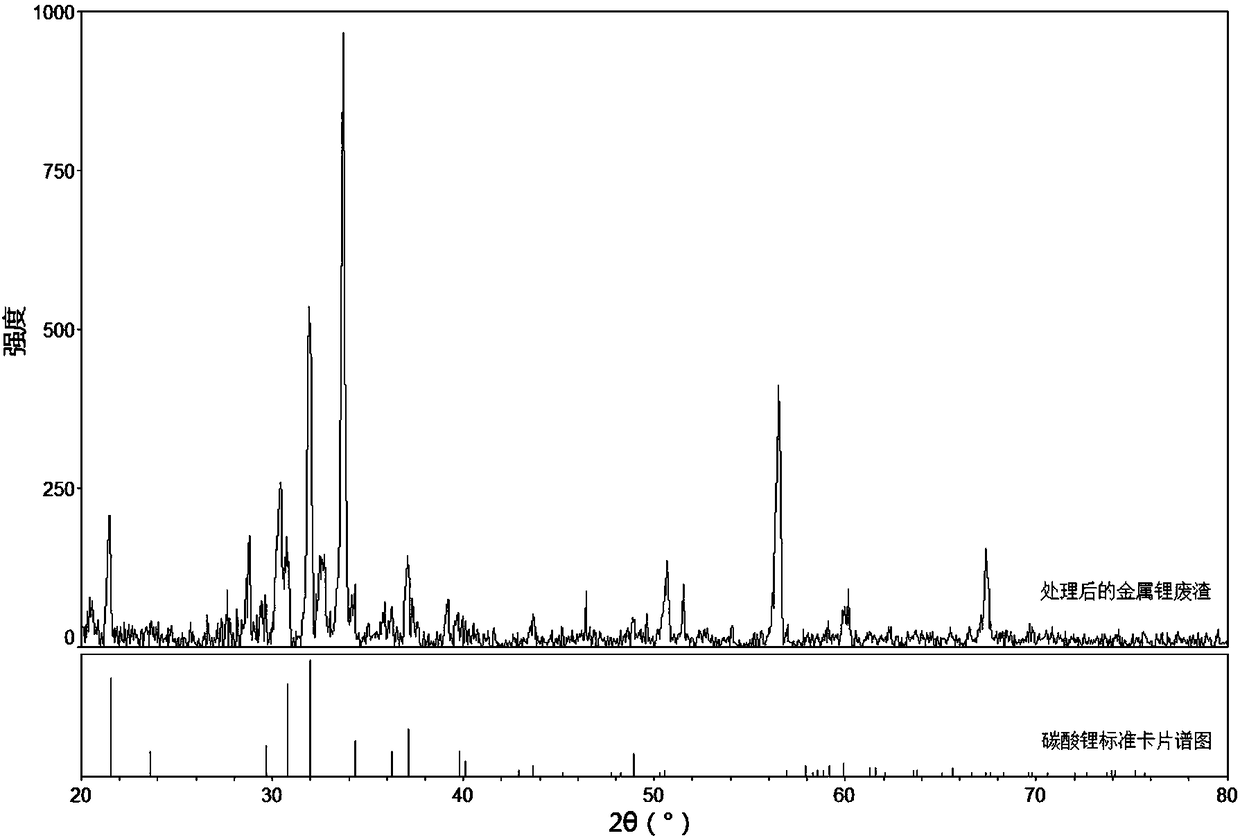

Embodiment 1

[0060] Follow the steps below to dispose of metal lithium waste:

[0061] 1. Take the metal lithium waste slag and test its composition. The content of Li element is 62.1%;

[0062] 2. Take 10g of metal lithium waste slag and place it in a tray with a layer of stainless steel mesh, and then put it into a closed heater;

[0063] 3. After placing the metal lithium waste slag, seal the heater;

[0064] 4. Pour industrial-grade carbon dioxide (purity ≥99.2%) into the closed heater at a flow rate of 2L / min, and discharge the air in the closed heater to the gas collecting tank for recovery;

[0065] 5. After introducing carbon dioxide for 5 minutes, start to heat up the enclosed heater at a temperature increase rate of 10°C / min;

[0066] 6. Raise the temperature of the closed heater to 300°C and keep it for 30 minutes;

[0067] 7. Perform natural cooling. Increase the flow rate of industrial-grade carbon dioxide to 3L / min during the cooling process to prevent outside air from entering;

[0068] ...

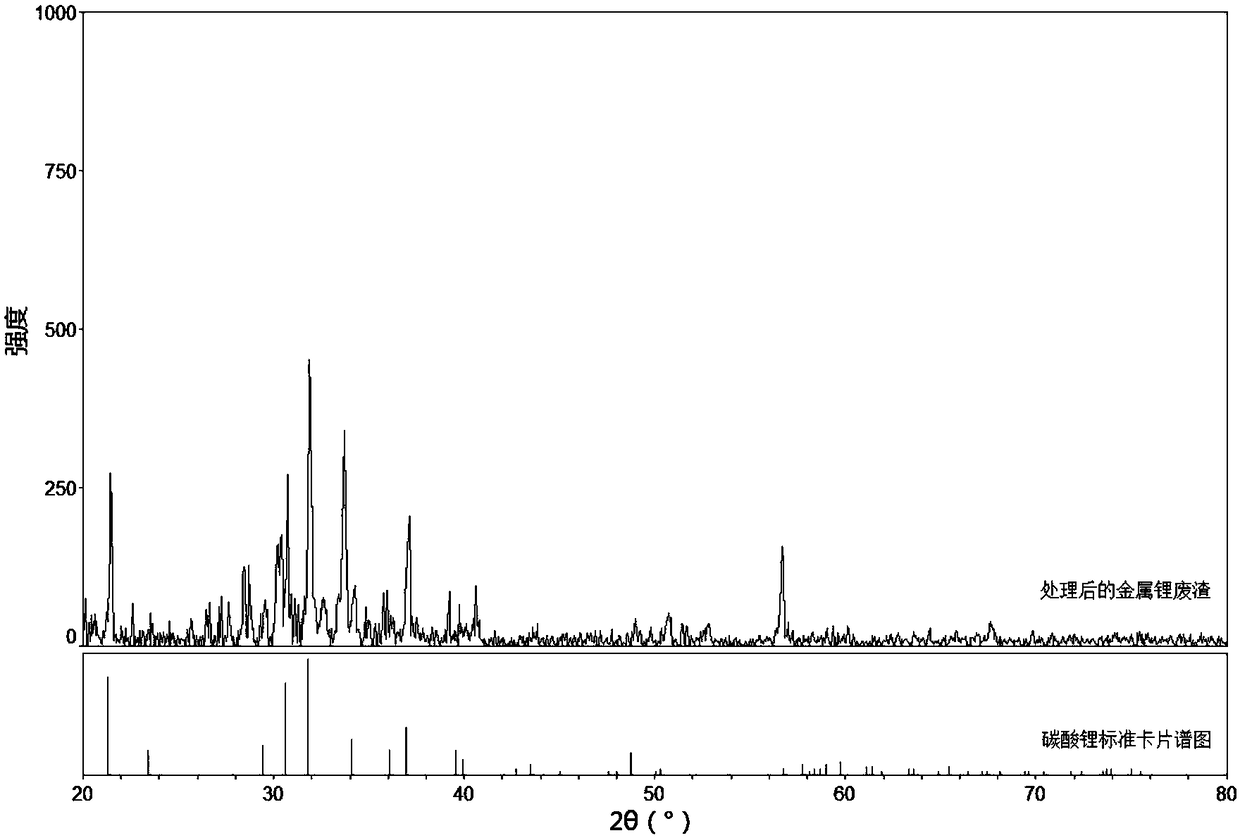

Embodiment 2

[0074] Follow the steps below to dispose of metal lithium waste:

[0075] 1. Take the metal lithium waste slag and test its composition. The content of Li element is 64.3%;

[0076] 2. Take 10g of metal lithium waste slag and place it in a tray with a layer of stainless steel mesh, and then put it into a closed heater;

[0077] 3. After placing the metal lithium waste slag, seal the heater;

[0078] 4. Pour industrial-grade carbon dioxide (purity ≥99.2%) into the closed heater at a flow rate of 2L / min, and discharge the air in the closed heater to the gas collecting tank for recovery;

[0079] 5. After introducing carbon dioxide for 5 minutes, start to heat up the enclosed heater at a temperature increase rate of 10°C / min;

[0080] 6. Raise the temperature of the enclosed heater to 500℃ and keep it for 30min;

[0081] 7. Perform natural cooling. Increase the flow rate of industrial-grade carbon dioxide to 3L / min during the cooling process to prevent outside air from entering;

[0082] 8. A...

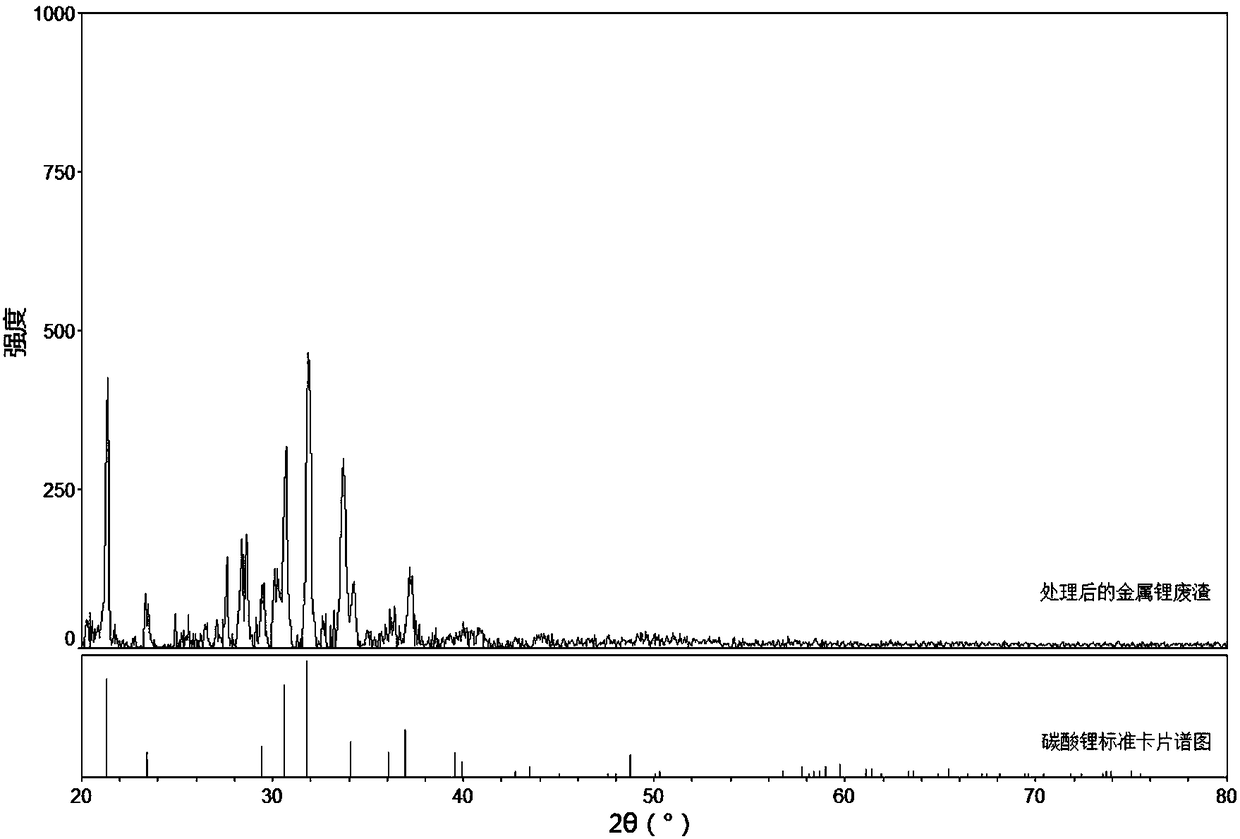

Embodiment 3

[0088] Follow the steps below to dispose of metal lithium waste:

[0089] 1. Take the metal lithium waste slag and test its composition. The content of Li element is 63.7%;

[0090] 2. Take 100g of metal lithium waste slag and place it on a tray with a layer of stainless steel mesh, and then put it into a closed heater;

[0091] 3. After placing the metal lithium waste slag, seal the heater;

[0092] 4. Pour industrial-grade carbon dioxide (purity ≥99.2%) into the closed heater with a flow rate of 10L / min, and discharge the air in the closed heater to the gas collecting tank for recovery;

[0093] 5. After introducing carbon dioxide for 10 minutes, start heating the closed heater at a heating rate of 10°C / min;

[0094] 6. Raise the temperature of the enclosed heater to 800°C and keep it warm for 60 minutes;

[0095] 7. Perform natural cooling. Increase the flow rate of industrial-grade carbon dioxide to 12L / min during the cooling process to prevent outside air from entering;

[0096] 8. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com