Regular quadrangular prism nickel vanadate nanomaterial and preparation method thereof

A technology of nanomaterials and square prisms, which is applied in the field of square prism nickel vanadate nanomaterials and its preparation, to achieve the effects of novel structure, good electron conduction and ion diffusion ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 0.2g nickel nitrate, 0.04g vanadium pentoxide, and 0.3g PEG10000 into 25mL aqueous solution and stir to mix evenly to obtain a mixed solution;

[0031] (2) Put the mixed solution obtained in step (1) into a 45mL hydrothermal kettle, place it in an oven, and react at 180°C for 18h;

[0032] (3) After the reaction described in step (2), the hydrothermal kettle is naturally cooled to room temperature, and then the product is collected by centrifugation, washed with water three times, and then dried to obtain the square prism nickel vanadate nanomaterial.

[0033] figure 1 It is the SEM photo of the regular tetragonal prism nickel vanadate nanomaterial obtained in Example 1 at a multiple of 5 um. It can be seen from the figure that the length of the columnar body is about 5 μm.

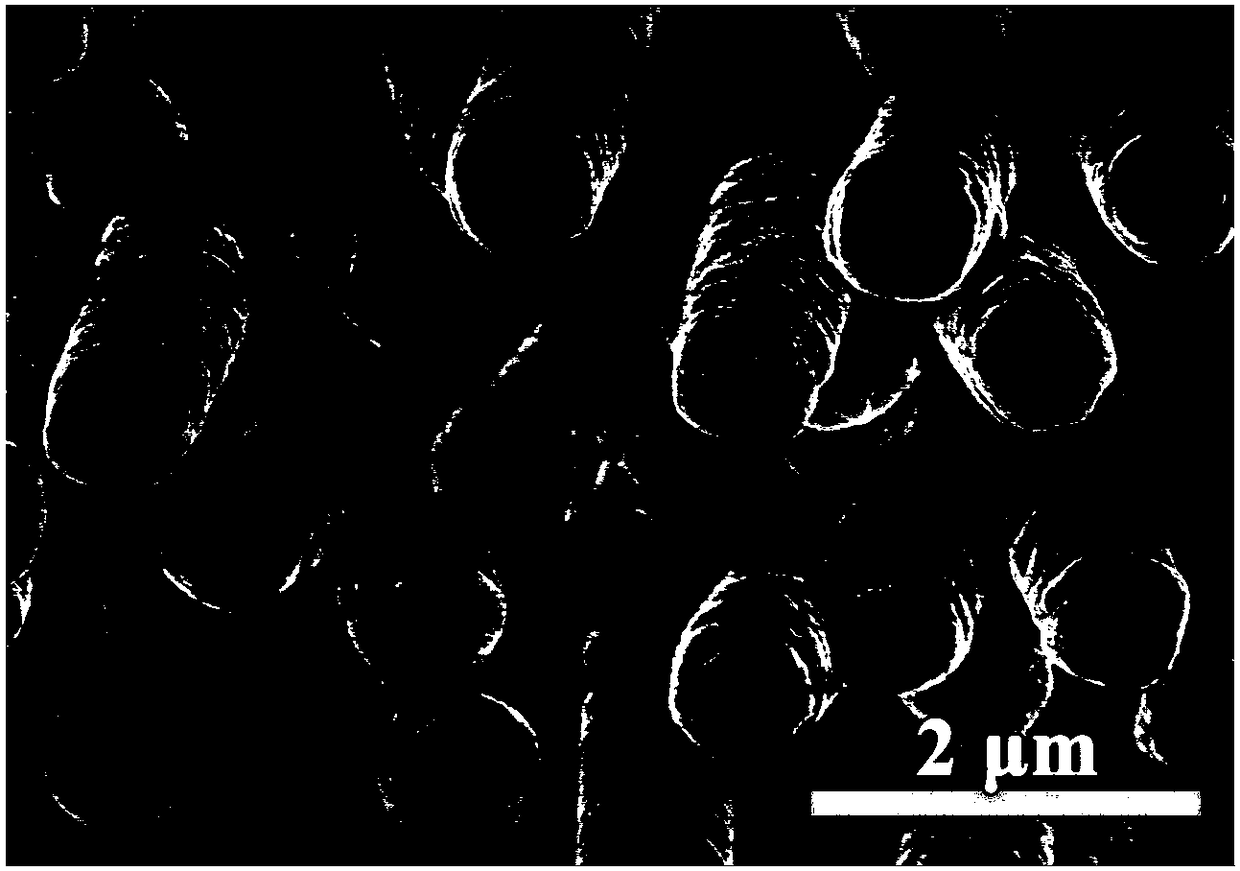

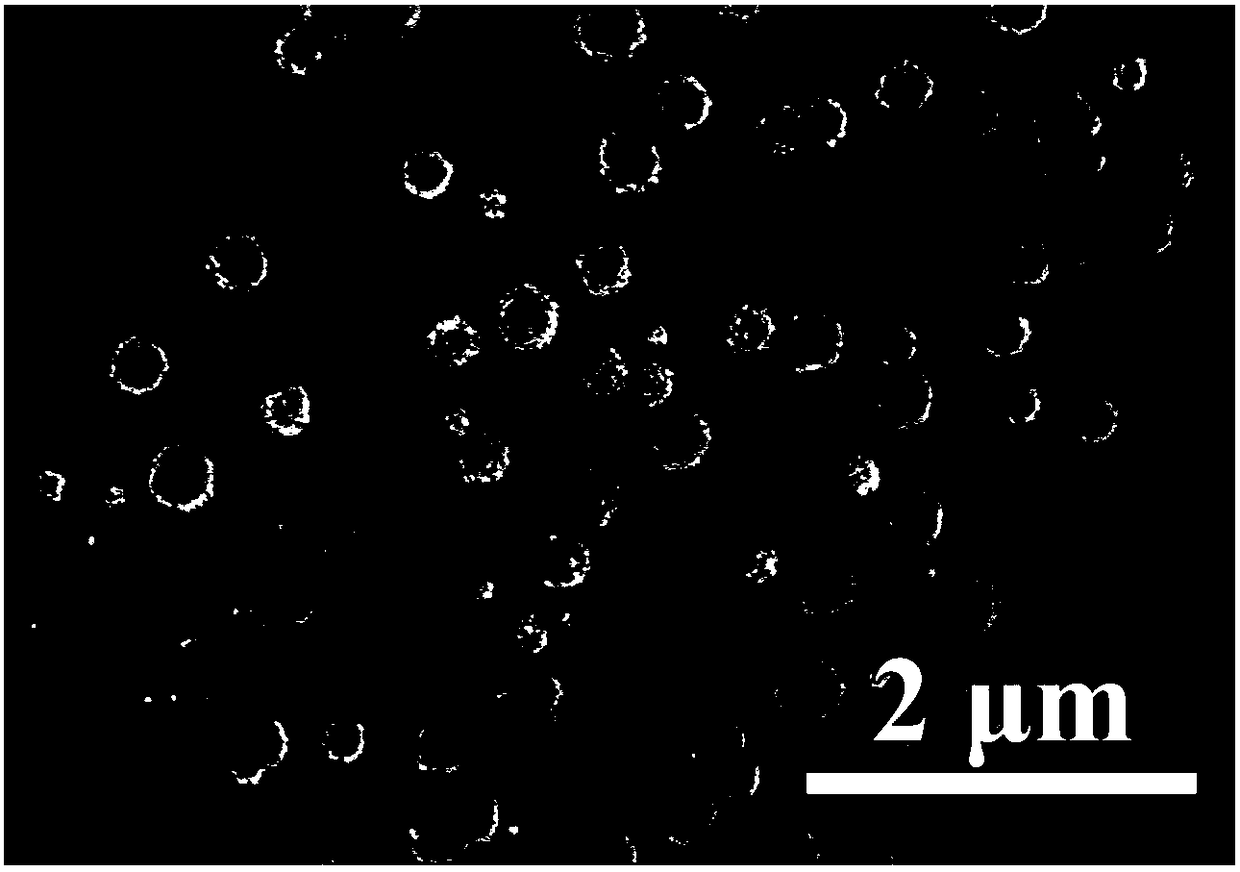

[0034] figure 2 It is the SEM photo of the regular tetragonal prism nickel vanadate nanomaterial obtained in Example 1 at a multiple of 2um. It can be seen from the figure that the bot...

Embodiment 2

[0039] (1) Add 0.3g of nickel nitrate, 0.06g of vanadium pentoxide, and 0.4g of PEG10000 into 25mL of aqueous solution and stir to mix evenly to obtain a mixed solution;

[0040] (2) Put the mixed solution obtained in step (1) into a 45mL hydrothermal kettle, place it in an oven, and react at 200°C for 12h;

[0041] (3) After the reaction described in step (2), the hydrothermal kettle is naturally cooled to room temperature, and then the product is collected by centrifugation, washed with water three times, and then dried to obtain the square prism nickel vanadate nanomaterial.

Embodiment 3

[0043] (1) Add 0.5g of nickel nitrate, 0.1g of vanadium pentoxide, and 0.4g of PEG10000 into 25mL of aqueous solution and stir to mix evenly to obtain a mixed solution;

[0044] (2) Put the mixed solution obtained in step (1) into a 45mL hydrothermal kettle, place it in an oven, and react at 160°C for 24h;

[0045] (3) After the reaction described in step (2), the hydrothermal kettle is naturally cooled to room temperature, and then the product is collected by centrifugation, washed with water three times, and then dried to obtain the square prism nickel vanadate nanomaterial.

[0046] The reagents used in the present invention are all purchased from Sinopharm Chemical Reagent Co., Ltd.; wherein, nickel nitrate, AR (Shanghai test), purity ≥ 98%; vanadium pentoxide, GR (Shanghai test), purity ≥ 99.5%; PEG10000, color Solid (Woke), relative molecular mass 8500-11500. The instrument used in the present invention is a conventional chemical instrument.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com