Sludge carbonization device and comprehensive utilization method

A sludge drying and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Ingenious and compact structure design and high energy recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described:

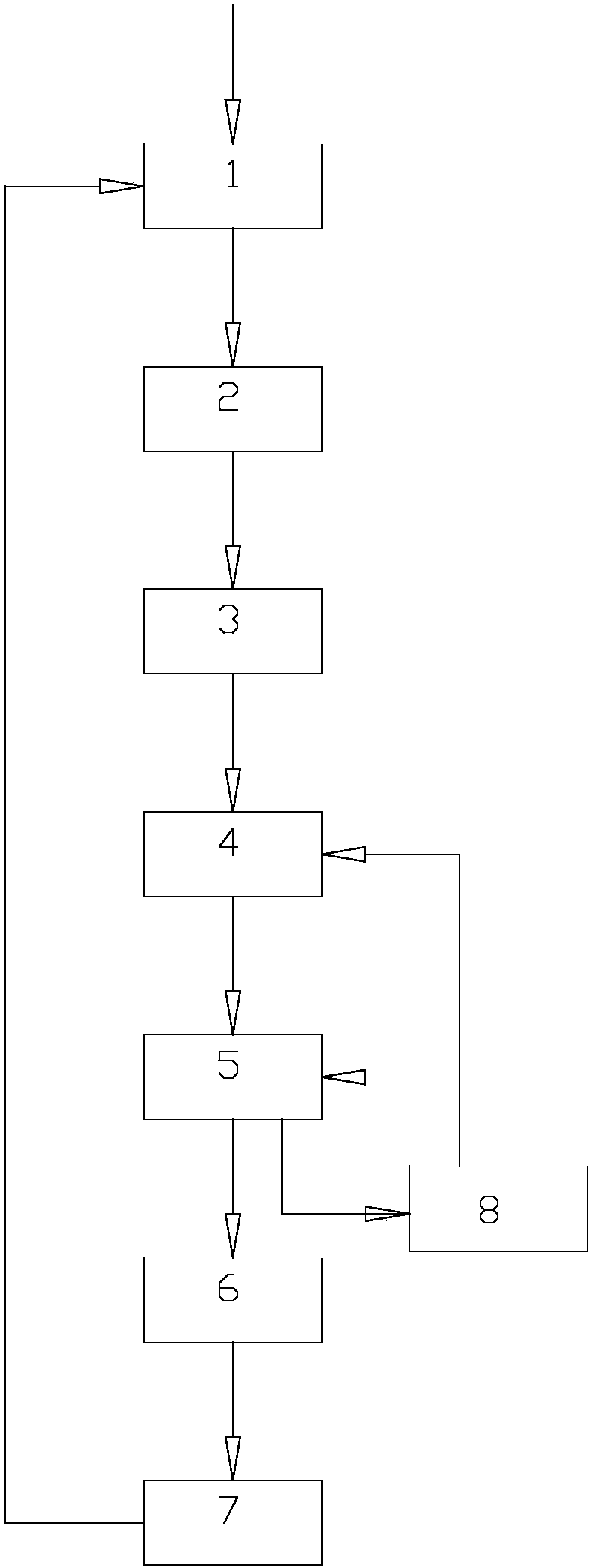

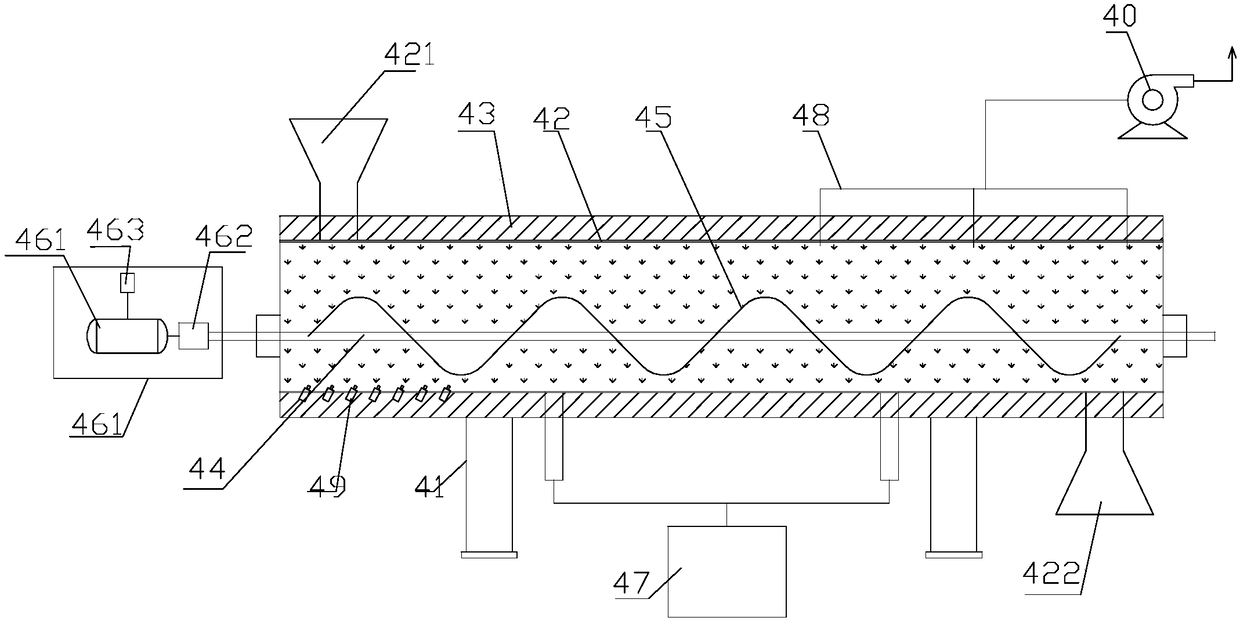

[0016] A method for sludge carbonization disposal and comprehensive utilization, such as figure 1 As shown, it includes the following steps: (A) After the concentrated sludge of the sewage treatment plant is collected, it first enters the sludge conditioning system 1 to add organic additives to the sludge and stir to adjust the calorific value of the sludge. The concentrated sludge The moisture content in the sludge is above 95%; (B) Dewater the conditioned sludge in the sludge plate and frame dewatering system 2, so that the moisture content in the sludge is reduced to below 70%; (C) The sludge after dehydration Crushing is carried out in the sludge crushing system 3; (D) the crushed sludge is dried in the sludge drying system 4, so that the moisture content of the sludge is reduced to below 25%, and the sludge material is dried in the sludge drying system. The residence time in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com